Concentrated filtering device and cleaning method of filter elements

A filtration device and filter element technology, which is applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of reduced porosity of membrane materials, inability to remove blockages, and high device operating costs, and achieves reduced operating costs and backwashing. Better results, lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

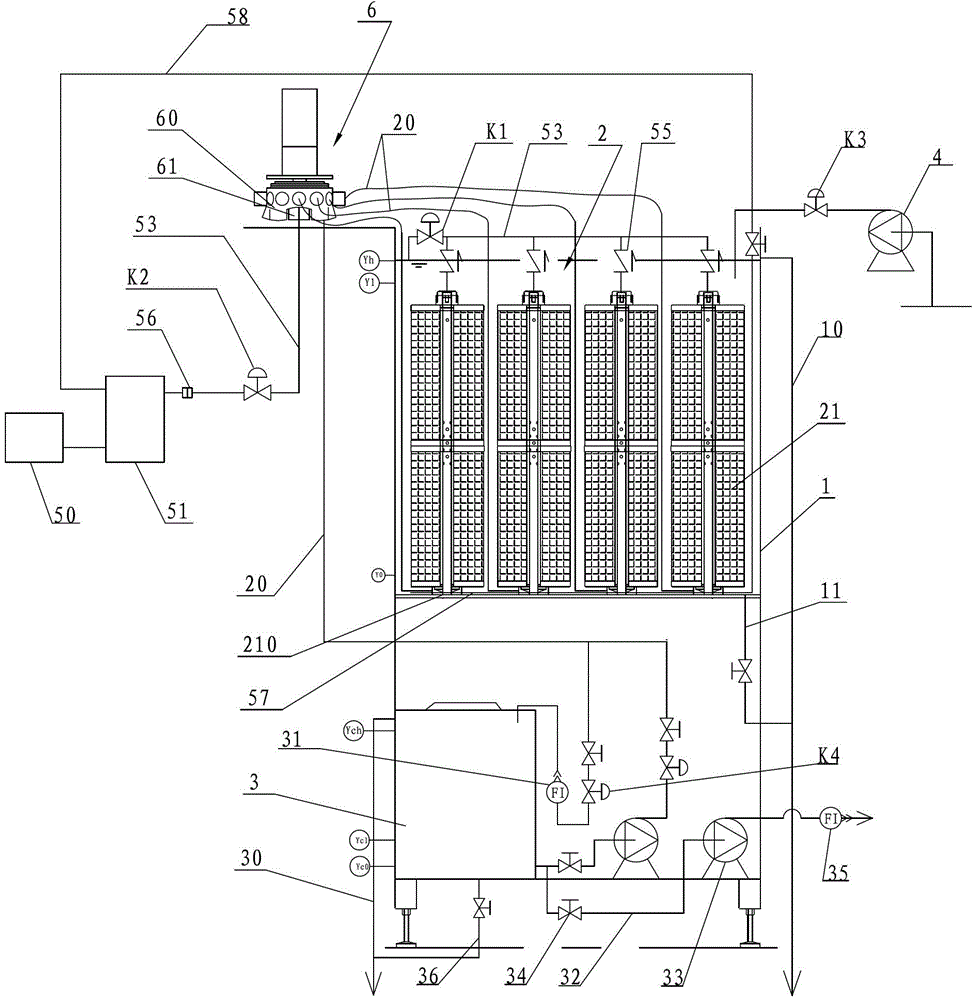

[0032] like figure 1 As shown, the concentrated filter device according to this embodiment mainly includes a filtered water tank 1, a filter element 2 (16 parallel filter elements 21) arranged in the filtered water tank, a produced water tank 3, a water inlet pump 4, a backwashing device, and a connection Auxiliary components such as pipes, switches, valves, etc.

[0033] The filter water tank 1 is located above the whole device, and its upper part is provided with the first liquid level point, the first liquid level point switch Yh, the second liquid level point and the first liquid level point switch Y1; its lower part is provided with the third liquid level point point and the third liquid level point switch Y0. The filter water tank overflow pipe 10 is connected to the upper part of the filter water tank 1, and the sewage discharge pipe 11 is connected to the bottom. 16 cylindrical filter elements 21 (see Chinese invention patent ZL201120063461.5 for the specific str...

Embodiment 2

[0047] like figure 2 As shown, the concentrated filtration device provided in this embodiment is basically the same as that in Embodiment 1, the difference is that the control valve 6 is located above the filtered water tank 1, and the water production pipe 20 is connected from the inside of the filtered water tank 1 to the installation base 210 at the bottom of the filter element 21 with control valve 6. The water production method of the filter element 21 is a siphon type. This method of water production also does not require electromechanical drive, and the working pressure is ≤0.02Mpa. The colloidal substances, microorganisms and suspended solids in the wastewater are only adsorbed on the surface of the membrane material and are easy to fall off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com