Rotation type foam fire suppression device

A foam fire extinguishing and rotating technology, which is applied in fire rescue and other fields, can solve the problems that the fire cannot be effectively controlled and spread, and achieve the effects of stable pressure, flexible and convenient use, and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

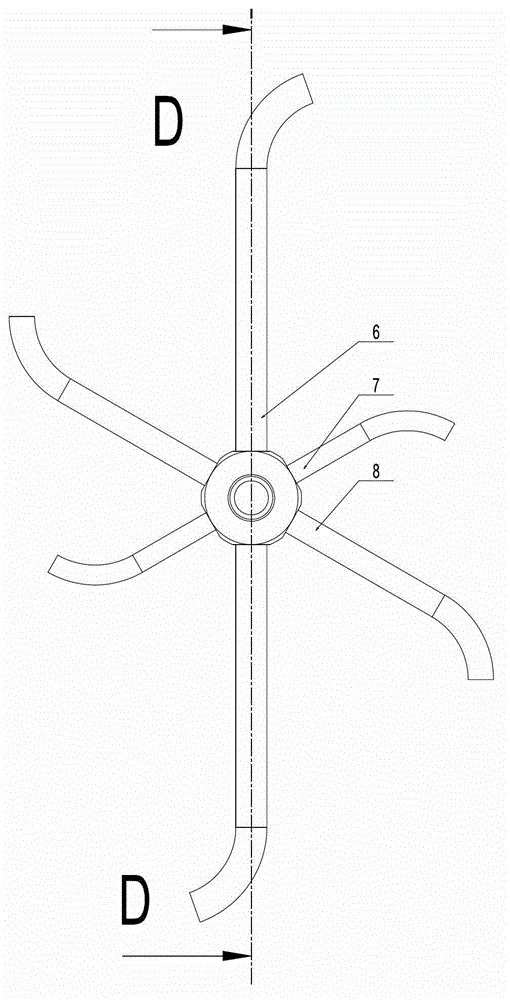

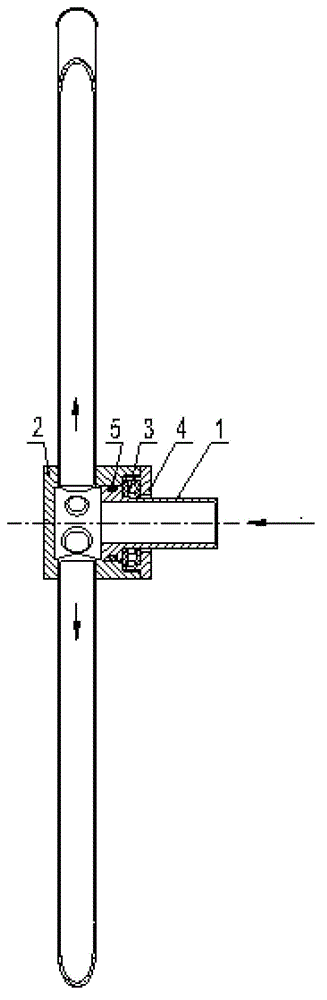

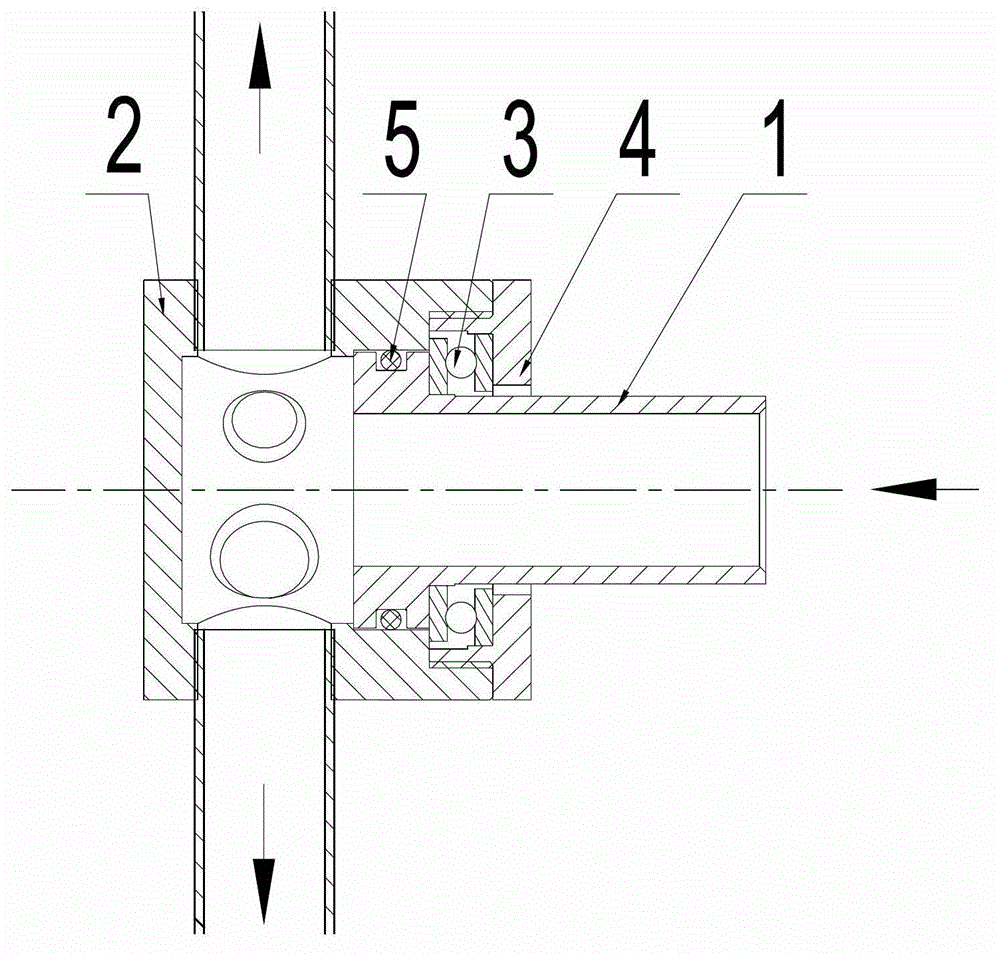

[0021] Referring to the accompanying drawings, a rotary foam fire extinguishing device includes a main cavity 2, and a plurality of outlet pipes 6, 7, 8 are arranged in a ring around the outside of the main cavity 2, and a water inlet pipe 1 is connected to the central hole of the main cavity 2, and the inlet The water pipe 1 communicates with each outlet pipe 6, 7, 8, the water inlet pipe 1 and the main cavity 2 are rotated through the plane thrust ball bearing 3, and the inner ring of the lower cover of the plane thrust ball bearing is in transition fit with the wall of the water inlet pipe, and the upper cover The outer ring and the inner cavity of the gland are transitionally fit; the flat thrust ball bearing 3 is pressed together with the gland 4, and the upper opening of the water inlet pipe 1 is provided with a groove, and the O-ring 5 is set in the groove, and the main cavity 2 A threaded hole is provided on the side wall, and the outlet pipe is connected with the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com