Broken nail extractor

A technology of extractor and hollow ring, which is applied in the field of medical devices, can solve the problems of screw breakage, large bone damage, prolonging operation time, etc., and achieve the effect of avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

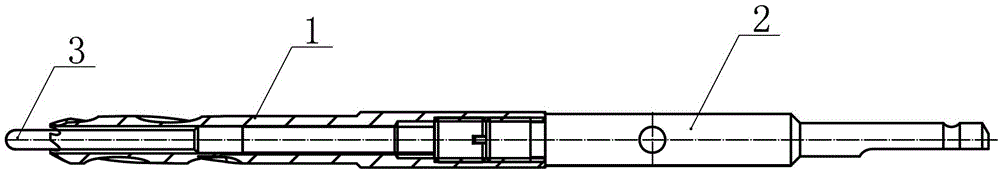

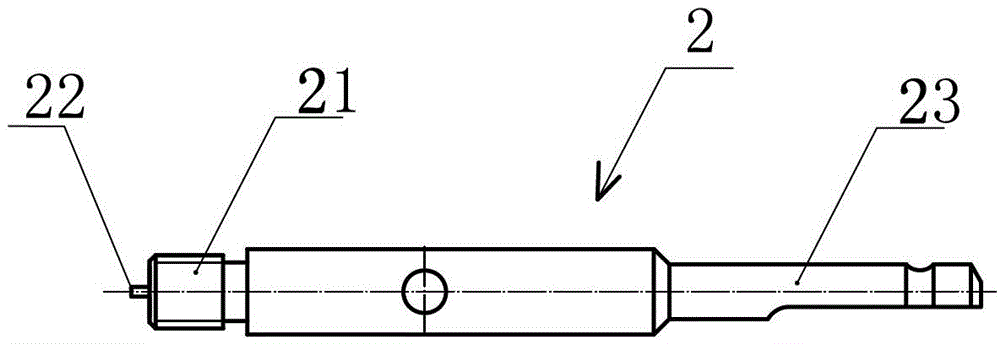

[0031] see Figure 1-Figure 7 Shown: a broken nail extractor, it includes a hollow trephine 1, a threaded needle 3, a connecting rod 2, the ring end of the head of the hollow trephine 1 is provided with a plurality of end teeth 15, this example is provided with 5 end teeth 15, the rear portion of the end teeth 15 is provided with a helical tooth 12, the center of the end teeth 15 is provided with a trephine inner hole 11, the outer rear portion of the end teeth 15 is tapered, and at the tapered rear end A drill-type spiral groove 16 is provided; an internal thread 13 is provided at the rear of the hollow trephine 1, and a threaded needle 3 is arranged in the hollow trephine 1, and the front end 33 of the threaded needle extends out of the trephine inner hole 11, and the thread The rear end of the needle 3 is provided with a connecting rod 2, and the rear part of the connecting rod 2 is a connecting handle 23.

[0032] The threaded needle rear end 31 is arranged in the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com