Coffee or cocoa composite particle filtering bar and manufacturing method thereof

A technology of composite particles and coffee, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problem of loss of tobacco taste, etc., achieve the effect of modifying the state and concentration of smoke, easy to remove, and improve the degree of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

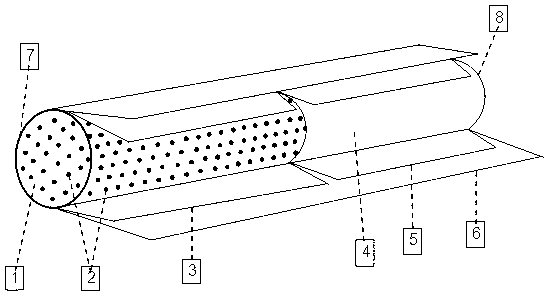

Image

Examples

Embodiment 1

[0032] S1. Granulation: Grinding commercially available coffee beans to a particle size of 40 mesh or purchased coffee powder with a particle size of about 40 mesh to obtain coffee granules;

[0033] S2. Dispersion: According to the ratio of the coffee particles after balancing moisture to 10% of the mass of the acetate fiber substrate, the particles obtained in S2 are evenly dispersed on the acetate tow (commercially available) for ordinary cigarettes after opening to obtain a composite granular tow;

[0034] S3. Molding: the composite particle filter rod is prepared by wrapping the solid particle tow with composite particle filter rod forming paper.

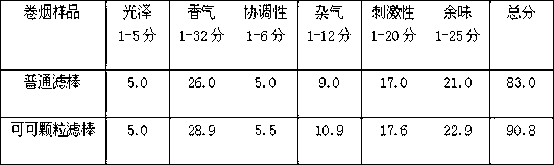

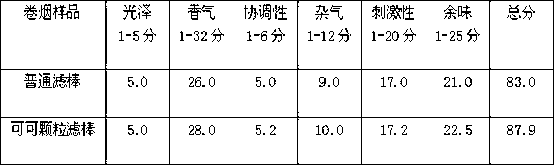

[0035] The smoke analysis of the filter rods by using the smoking machine method for conventional analysis in GB / T19609-2004 shows that the use of cigarettes containing coffee particle filter rods can effectively reduce the smoke The amount of tar in the gas is 5%, and the content of volatile aldehydes is red...

Embodiment 2

[0044] S1. Granulation: Grinding commercially available coffee beans to a particle size of 40 mesh or purchased coffee powder with a particle size of about 40 mesh to obtain coffee granules;

[0045] S2. Flavoring treatment: add coffee tincture (commercially purchased) accounting for 0.03% of the mass of coffee granules to the coffee granules described in S1, and mix evenly;

[0046]S3. Balance: put the granules obtained in S2 into a constant temperature and humidity box to balance the moisture for 48 hours, so that the moisture content is about 10%;

[0047] S4. Dispersion: according to the ratio of the coffee particles after balancing moisture to 10% of the mass of the acetate fiber substrate, the particles obtained in S3 are evenly dispersed on the acetate tow (commercially available) for common cigarettes after opening to obtain a composite granular tow;

[0048] S5. Forming: the composite particle filter rod is prepared by wrapping the solid particle to...

Embodiment 3

[0058] S1. Granulating: crush commercially available cocoa beans to a particle size of 40 mesh or purchase cocoa powder with a particle size of about 40 mesh to obtain cocoa granules;

[0059] S2. Dispersion: according to the proportion of cocoa particles accounting for 10% of the mass of the cellulose acetate base material, the particles obtained in S1 are evenly dispersed on the acetate tow (commercially available) for common cigarettes after opening, to obtain the tow containing composite particles;

[0060] S3. Molding: the composite particle filter rod is prepared by wrapping the solid particle tow with composite particle filter rod forming paper.

[0061] The smoke analysis of the filter sticks using the smoking machine test method for routine analysis of GB / T19609-2004 shows that the use of cigarettes containing cocoa particle filter sticks can effectively reduce the smoke The amount of tar in the gas is 3%. In the filter rod provided in this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com