Production method for black garlic with high amino acid content

A production method and high amino acid technology, applied in application, food preparation, food science and other directions, to achieve the effects of high-efficiency functional food, reduced production cost, and high-efficiency therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

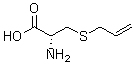

Image

Examples

Embodiment 1

[0038] Cleaning of raw materials: Select ungerminated garlic with a plump appearance, remove the soil and other impurities on the surface of the garlic, and ferment with the skin on.

[0039] Ultra-high pressure kinase: Vacuum-pack the cleaned and fermented garlic, put it into the ultra-high pressure chamber, set the pressure at 100Mpa, and take it out after 15 minutes of treatment.

[0040]Variable temperature fermentation: includes the following three stages:

[0041] High-temperature and high-humidity Maillard reaction: Remove the vacuum-packed garlic after ultra-high pressure treatment, put it in a fermentation box, keep the temperature at 70°C, and control the relative humidity at 90%RH for 120 hours.

[0042] Medium-temperature and medium-humidity stage: After the high-temperature and high-humidity reaction is completed, the garlic is cooled and dehumidified, and the temperature is kept at 60°C, and the relative humidity is controlled at 70%RH for 48 hours.

[0043] Nor...

Embodiment 2

[0048] Cleaning of raw materials: Select ungerminated garlic with a plump appearance, remove the soil and other impurities on the surface of the garlic, and ferment with the skin on.

[0049] Ultra-high pressure kinase: Vacuum-pack the cleaned and fermented garlic, put it into the ultra-high pressure chamber, set the pressure at 350Mpa, and take it out after 30 seconds of treatment.

[0050] Variable temperature fermentation: includes the following three stages:

[0051] High-temperature and high-humidity Maillard reaction: Remove the vacuum-packed garlic after ultra-high pressure treatment, put it into a fermentation box, keep the temperature at 85°C, and control the relative humidity at 70%RH for 48 hours.

[0052] Medium-temperature and medium-humidity stage: After the high-temperature and high-humidity reaction is completed, the garlic is cooled and dehumidified, and the temperature is kept at 75°C, and the relative humidity is controlled at 60%RH for 24 hours.

[0053] N...

Embodiment 3

[0058] Cleaning of raw materials: Select ungerminated garlic with a plump appearance, remove the soil and other impurities on the surface of the garlic, and ferment with the skin on.

[0059] Ultra-high pressure kinase: Vacuum-pack the cleaned and fermented garlic, put it into the ultra-high pressure chamber, set the pressure at 200Mpa, and take it out after 8 minutes of treatment.

[0060] Variable temperature fermentation: includes the following three stages:

[0061] High-temperature and high-humidity Maillard reaction: Remove the vacuum-packed garlic after ultra-high pressure treatment, put it into a fermentation box, keep the temperature at 80°C, and control the relative humidity at 80%RH for 60 hours.

[0062] Medium-temperature and medium-humidity stage: After the high-temperature and high-humidity reaction is completed, the garlic is cooled and dehumidified, and the temperature is kept at 65°C, and the relative humidity is controlled at 65%RH for 40 hours.

[0063] No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com