Voltage-multiplying-type high-voltage rectifying oil tank

A high-voltage rectifier and fuel tank technology, applied in X-ray equipment, electrical components, etc., can solve the problems of large high-voltage ripple, large volume, and high cost, and achieve the effects of small high-voltage ripple, high imaging clarity, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

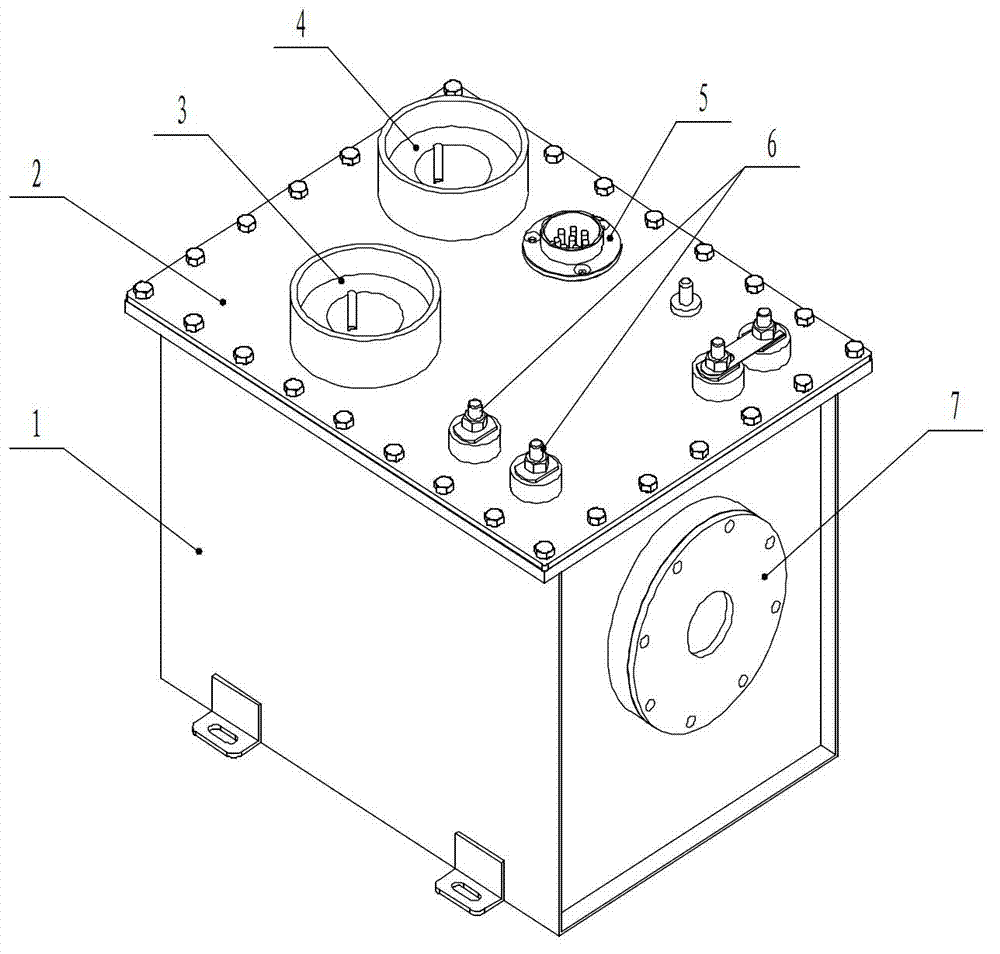

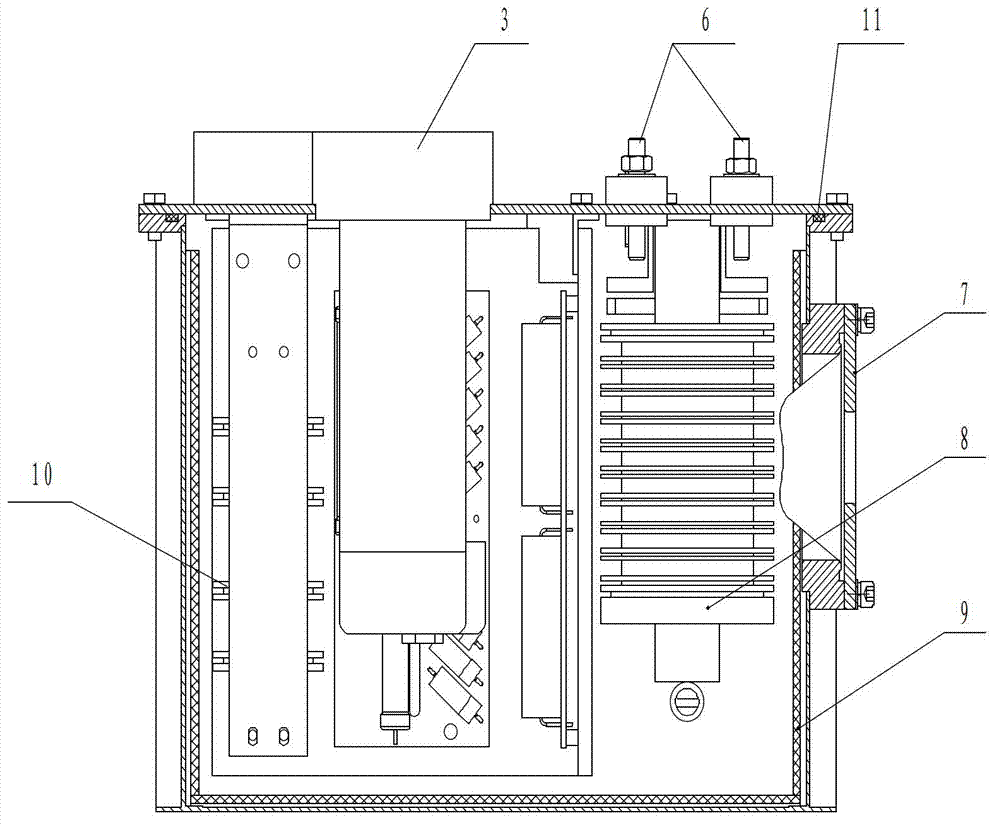

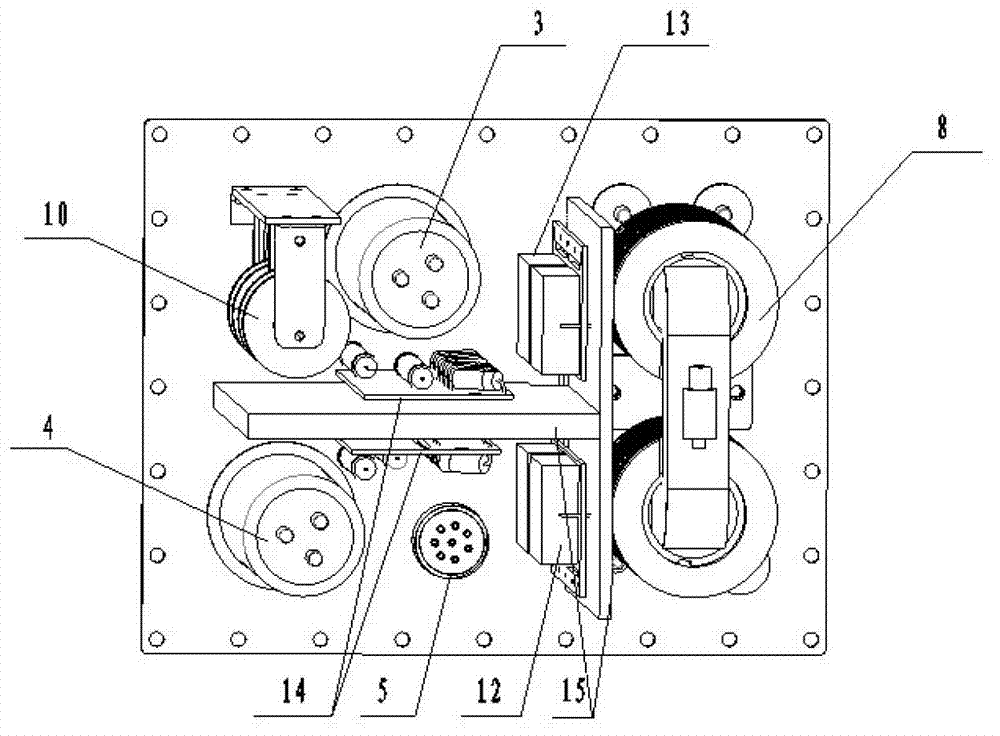

[0025] like figure 1 , figure 2 ,and image 3 As shown, the 20kw pressure doubler high-voltage fuel tank includes fuel tank body 1, tank cover 2, high-frequency high-voltage transformer 8, filament transformer 10, sampling circuit 14, positive terminal voltage doubler rectifier 12, negative terminal voltage doubler rectifier 13, fixedly installed on The bottom of the box cover with brackets, the high-frequency high-voltage transformer 8 and the filament transformer are respectively installed on a well-made bracket under the box cover, the sampling circuit and the positive terminal voltage doubler rectifier are installed on the epoxy board fixed with the bracket, and the sealing ring 11 Surround is placed on the junction of box body and box cover, and insulating plate 9 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com