High-frequency and high-voltage oil tank with single bed and single tube

A high-frequency, high-voltage, fuel tank technology, applied in X-ray equipment, electrical components, etc., can solve problems such as large ripples, easy ignition of fuel tanks, and unstable output of high-frequency and high voltage, so as to achieve less soft rays and not easy to burn out , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

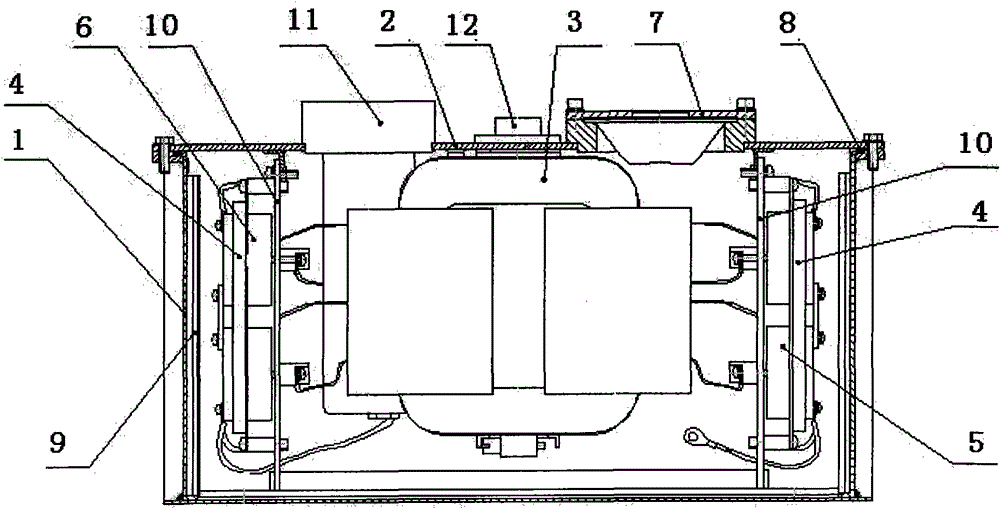

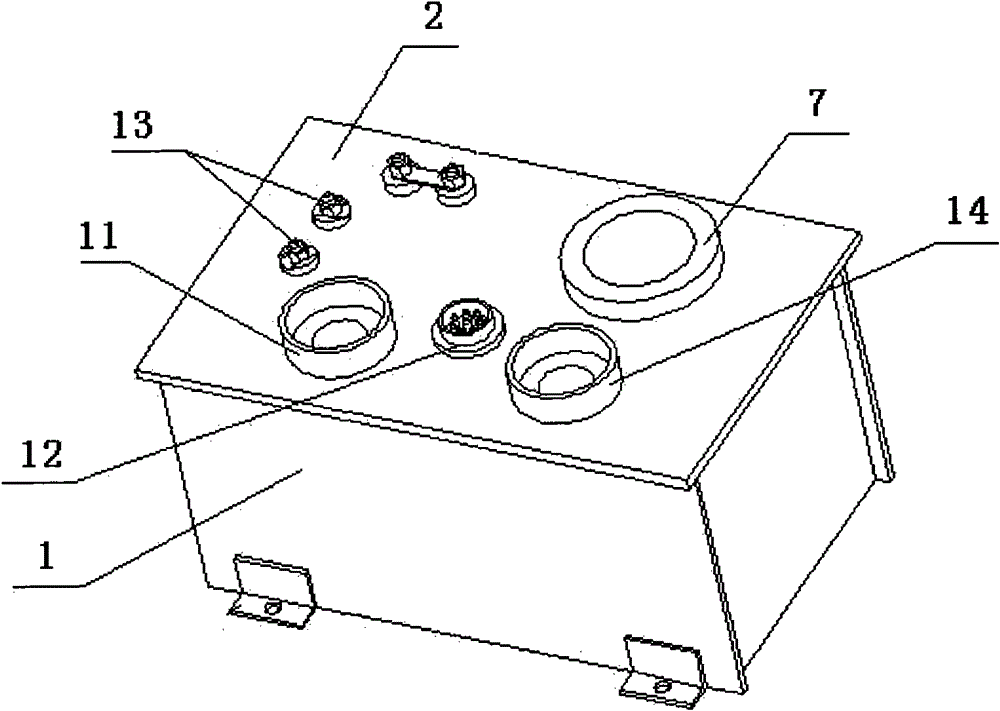

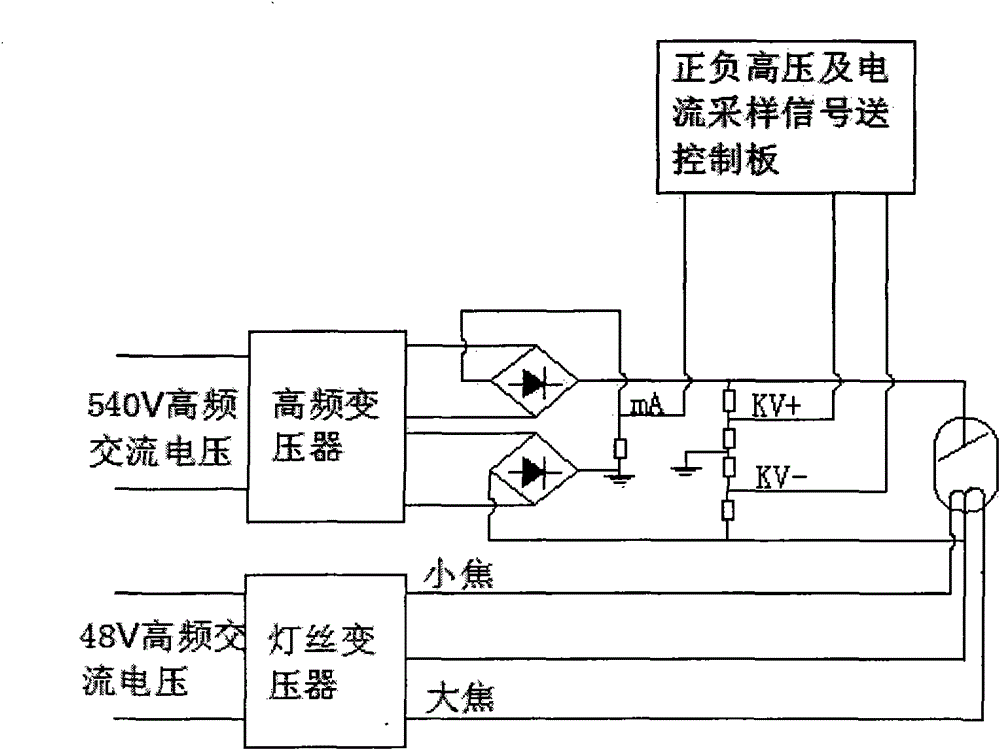

[0009] like figure 1 As shown, the single-bed single-tube high-frequency and high-voltage oil tank includes a fuel tank body 1, a fuel tank cover 2, a high-frequency high-voltage transformer 3, a positive and negative high-frequency high-voltage voltage sampling circuit 4, and rectifying silicon stacks 5 and 6. The high-frequency transformer 3 is installed on In the tank body 1, a sealing rubber pad 8 is installed in the groove directly above the tank body, an insulating plate 9 is installed on the inner bottom of the tank body 1 and both sides of the rectifying silicon stack, a high-frequency high-voltage transformer 3, and an expansion valve 7. The epoxy board 10 and the positive and negative high-voltage sockets 14 and 11 are fixedly installed on the fuel tank cover, the silicon rectifier stack and the voltage sampling circuit are installed on the epoxy board 10 in parallel, and the silicon rectifier stacks at the positive and negative terminals are respectively installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com