Graphene nanomaterial wire splicing fitting and splicing method

A technology of nanomaterials and splicing fittings, applied in the direction of connection, cable joint, line/collector parts, etc., can solve the problem of less research on splicing fittings, and achieve the effect of stable and reliable construction technology, mature technology, and guaranteeing power transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with example the present invention is described in detail.

[0036] The invention provides a splicing fitting and splicing method applied to an attached graphene nano material wire.

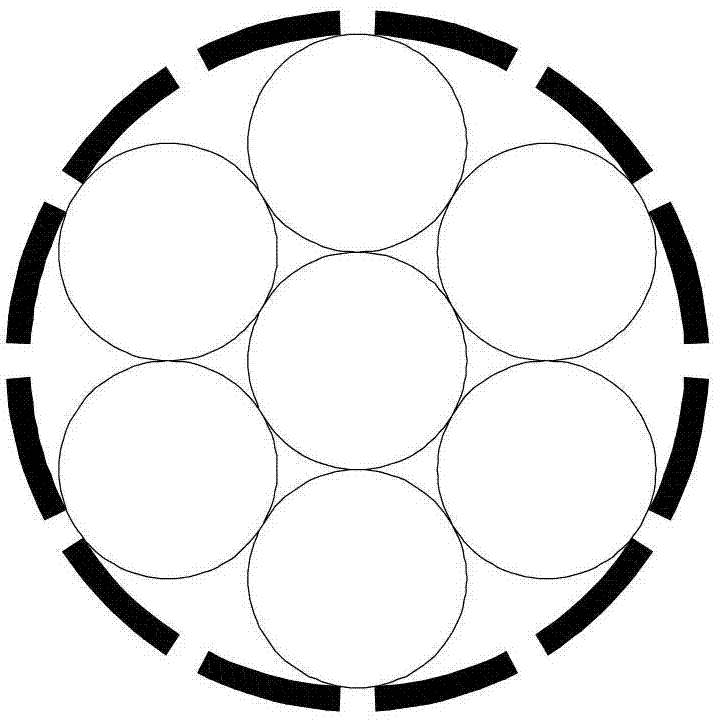

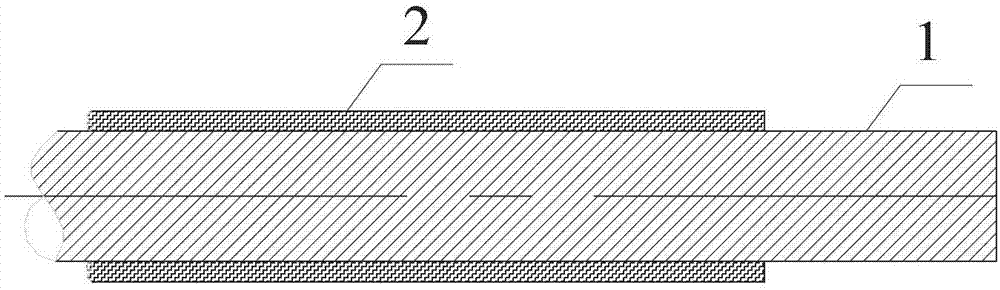

[0037] The structure of the attached graphene nanomaterial wire is as follows figure 1 As shown, the wire includes an inner layer 1 and an outer layer 2. The inner layer 1 is a circular tube of carbon fiber composite material, which is mainly used as a load bearing. Form a regular tubular structure. The outer layer 2 is a uniformly attached graphene nanomaterial sheet, which is arranged on the periphery of the inner layer. The graphene nanomaterial sheet has an arc-shaped structure and is the conductive part of the overhead transmission line conductor.

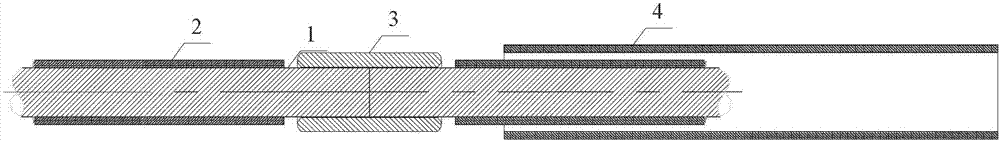

[0038] The connecting hardware includes a carbon fiber crimping connecting tube 3 and a graphene film connecting sleeve 4, which are respectively used for connecting the inner layer 1 and the outer layer 2.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com