Clamping device and levelling method for slice carrying table of ultrasonic scanning microscope

A technology of ultrasonic scanning and clamping device, which is used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. It can solve the problem of corrosion and rust of parts and fastening screws, loss of reliability, loss of operational flexibility and other problems to achieve the effect of preventing parts from rusting, simple operation and easy leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

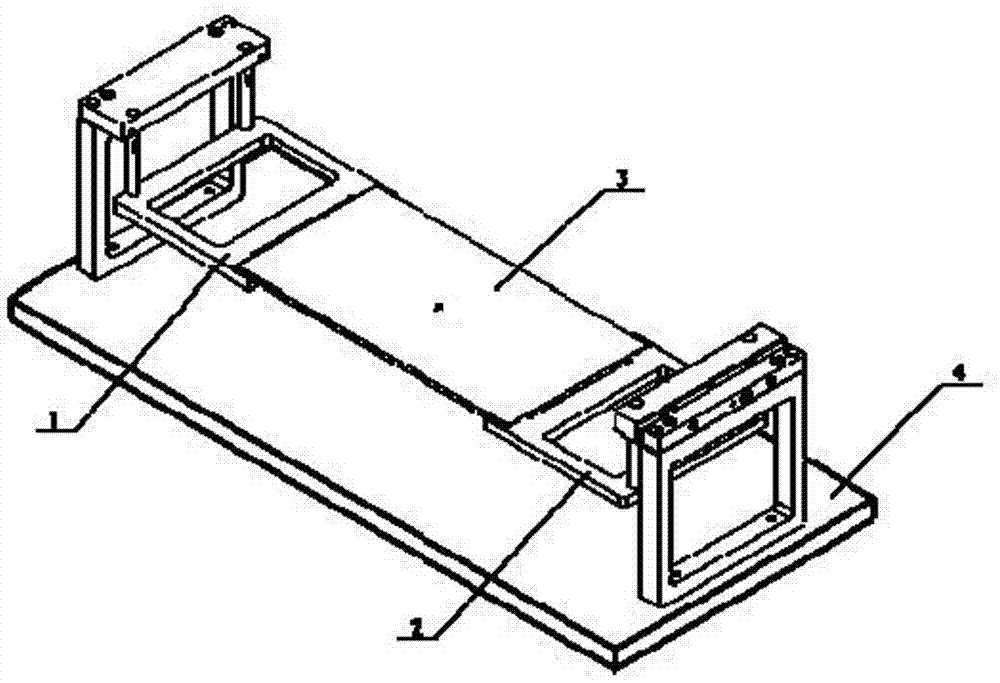

[0028] Such as figure 1 , Figure 8 As shown, the wafer stage clamping device of the ultrasonic scanning microscope of the present invention includes a base 4 and the wafer stage 3 or a standard magazine 24, and the wafer stage clamping device of the ultrasonic scanning microscope of the present invention is characterized in that: the base 4 A fixed bracket structure 1 and a movable bracket structure 2 are respectively fixed at both ends of the bracket, the fixed bracket structure 1 and the movable bracket structure 2 hold and clamp the wafer stage 3 or Standard cartridge 24.

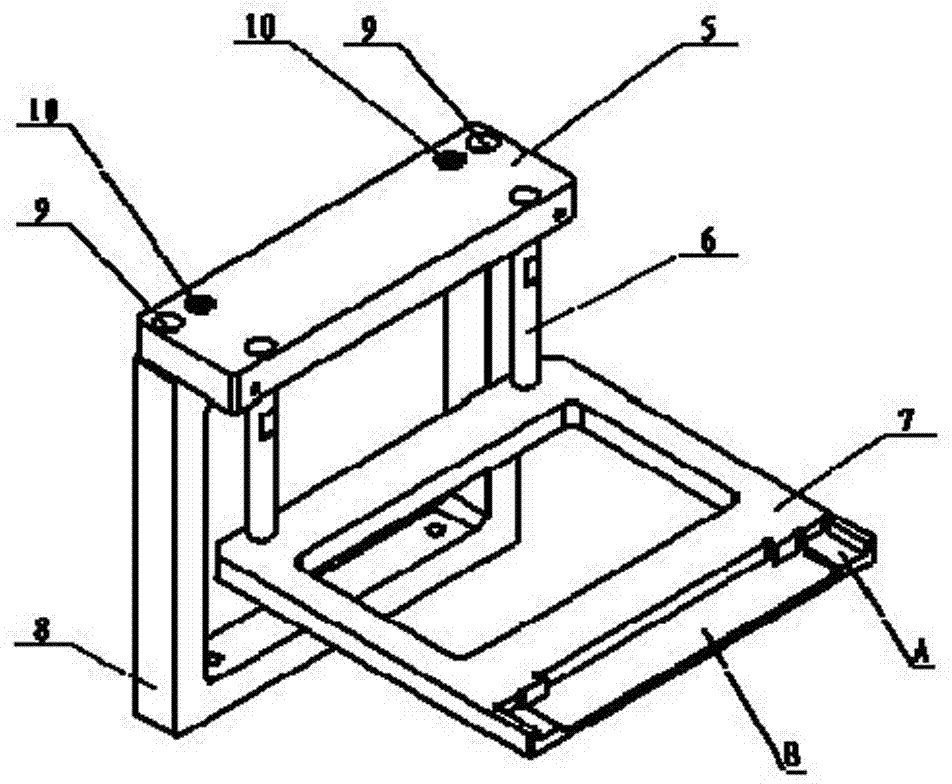

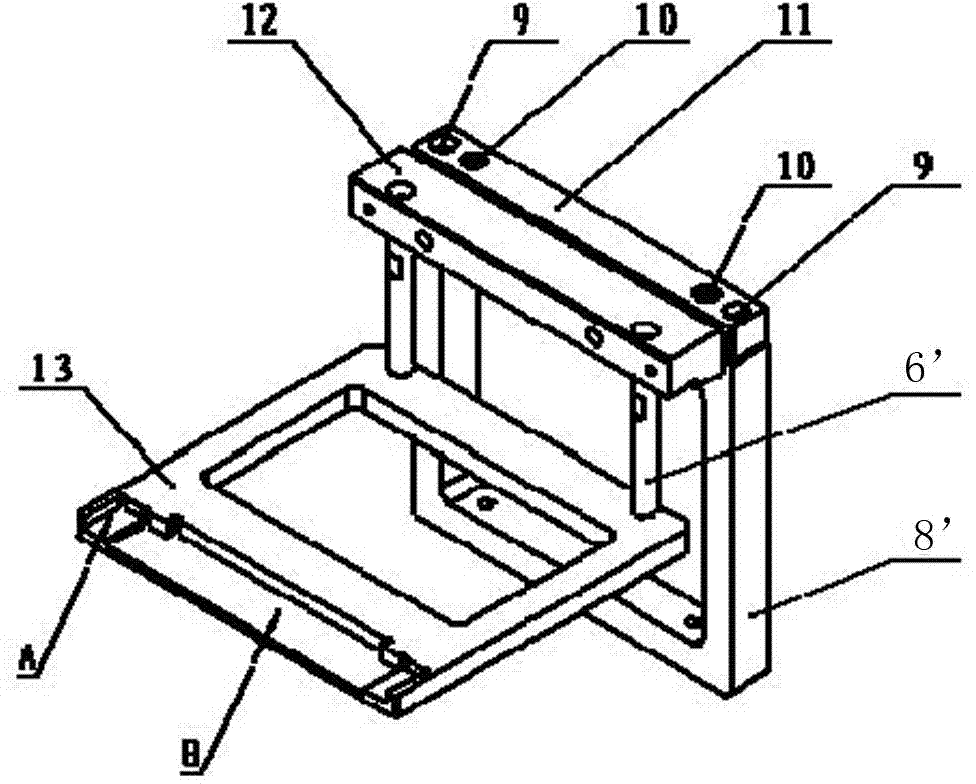

[0029] Such as figure 2 As shown, the fixed bracket structure 1 is composed of a left column 8, a left upper seat 5, a left column 6 and a left bracket 7. The bottom end of the left column 8 is fixed on the base 4 by screws, and the upper end is fixed by two The locking screw 9 and the two adjustment screws 10 are connected to the outside of the left upper seat 5, and the inner two ends of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com