Inner star wheel overrunning clutch

A technology of overrunning clutches and inner star wheels, which is applied to clutches, one-way clutches, mechanical equipment, etc., can solve the problems of affecting the bearing capacity of overrunning clutches, restrictions on the use of overrunning clutches, and the inability to arrange rolling elements along the axial direction, etc., to achieve reduction Effects of small size, volume reduction, and reduction in processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

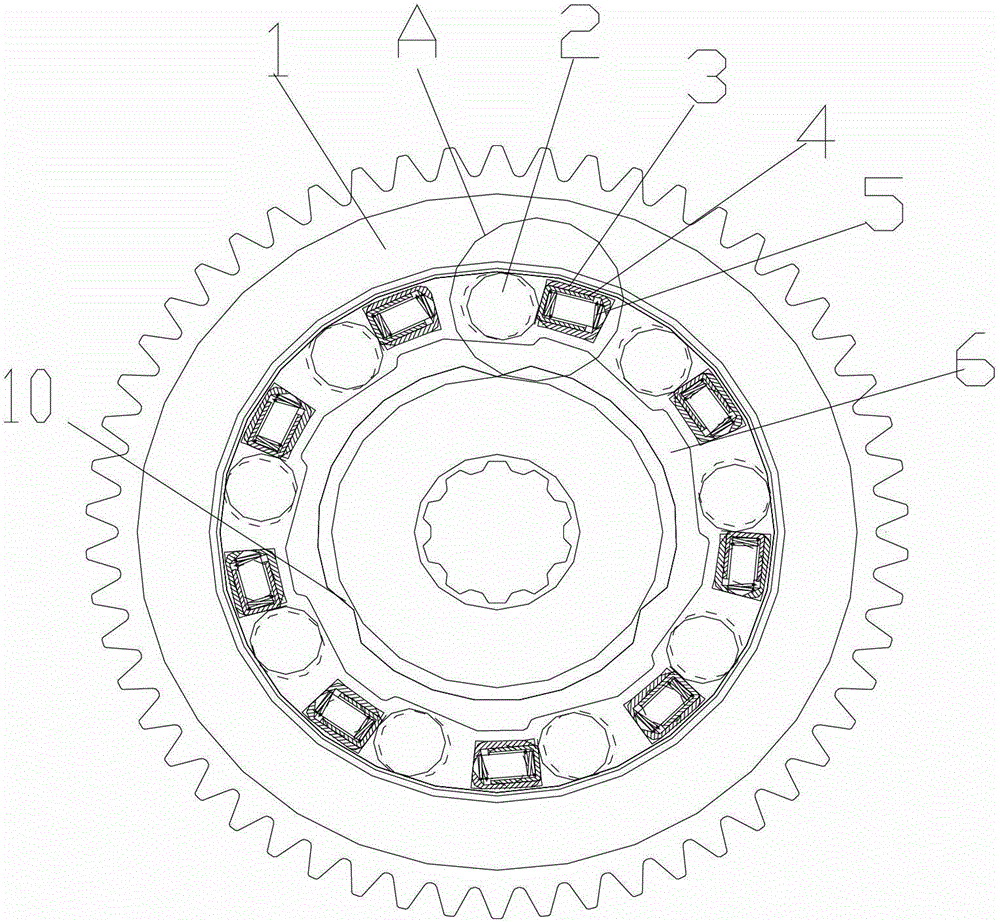

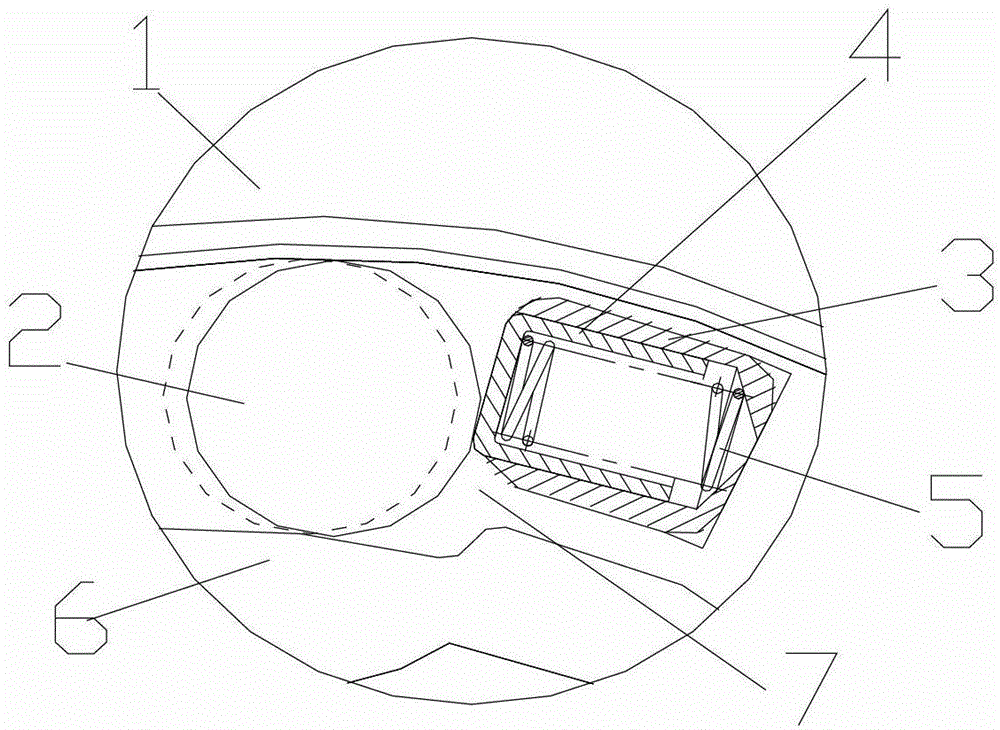

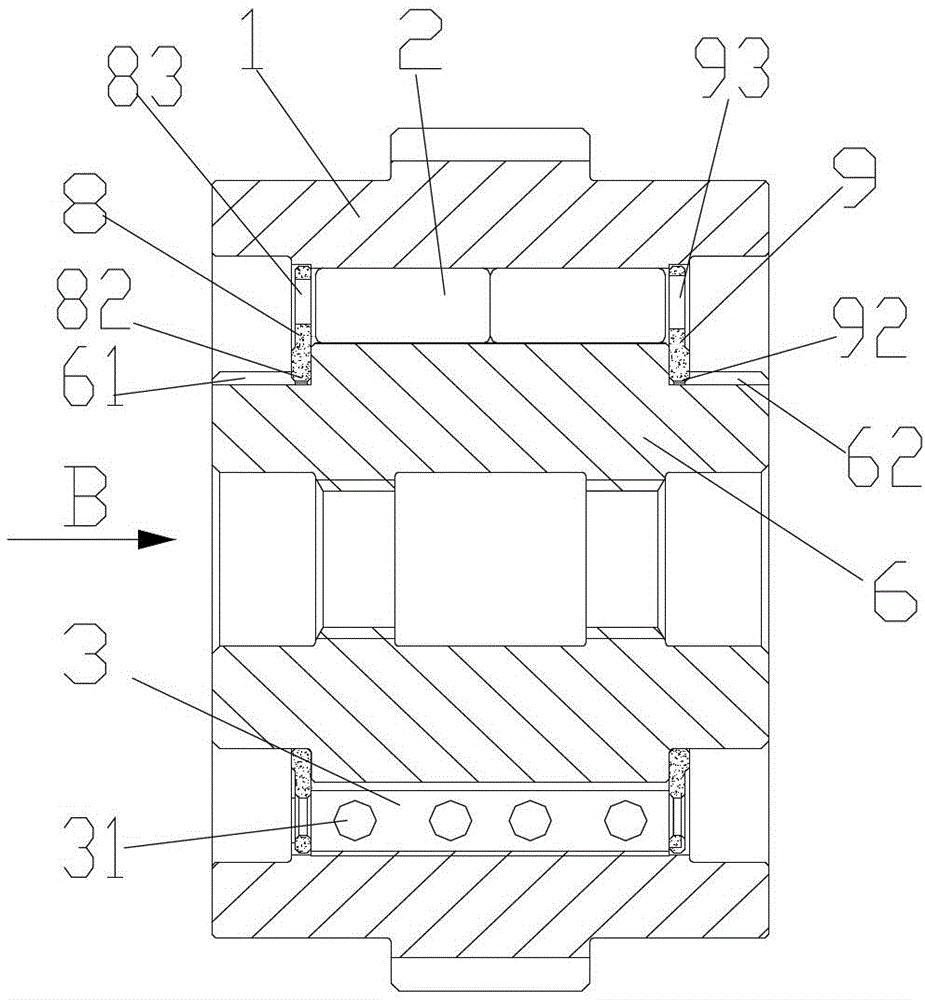

[0024] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 It is an axial sectional view of the present invention, Figure 4 for image 3 View along direction B, Figure 5 is the support shaft structure diagram, Image 6 for Figure 5 C direction view, as shown in the figure: the inner star wheel overrunning clutch of this embodiment includes an outer ring 1, an inner ring 6 and a roller 2, and the outer circle of the inner ring 6 is provided with a wedge-shaped groove, and the wedge-shaped groove and the outer The inner circle of the ring 1 jointly forms a wedge-shaped engagement space 7 for engaging or separating from the roller; it also includes a support shaft 3 that is arranged in a one-to-one correspondence with the roller 2 in the circumferential direction, and the support shaft 3 is at least circumferentially relative to the inner ring. The direction is detachably fixed, and the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com