Manufacture and installment method of cleaning room fire window and cleaning room fire window

An installation method and technology for fireproof windows, which are applied in the field of clean rooms, can solve the problems of high cost, poor fire resistance and heat resistance of carbon steel materials, and affecting the fireproof performance of fireproof windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

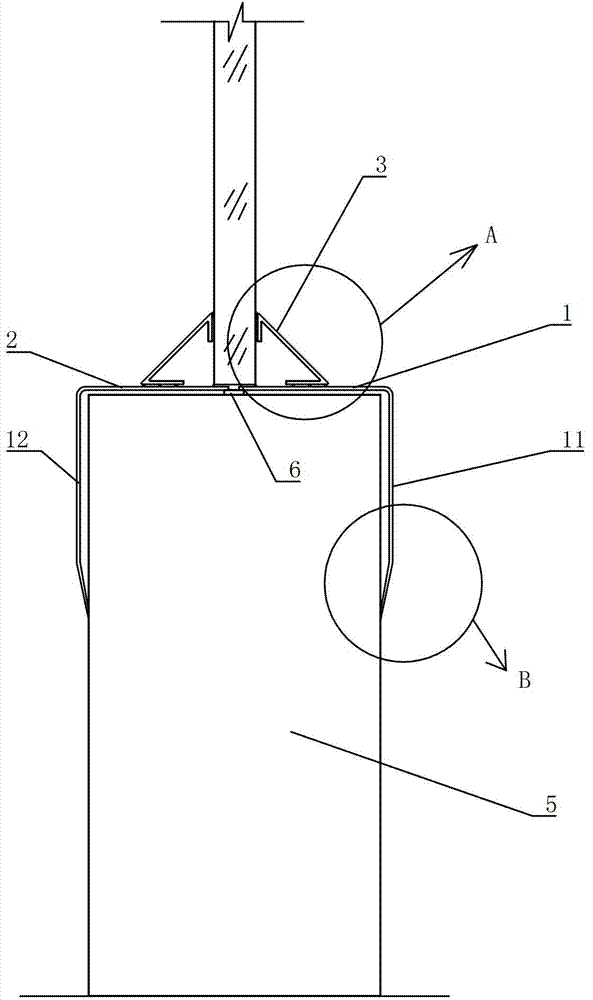

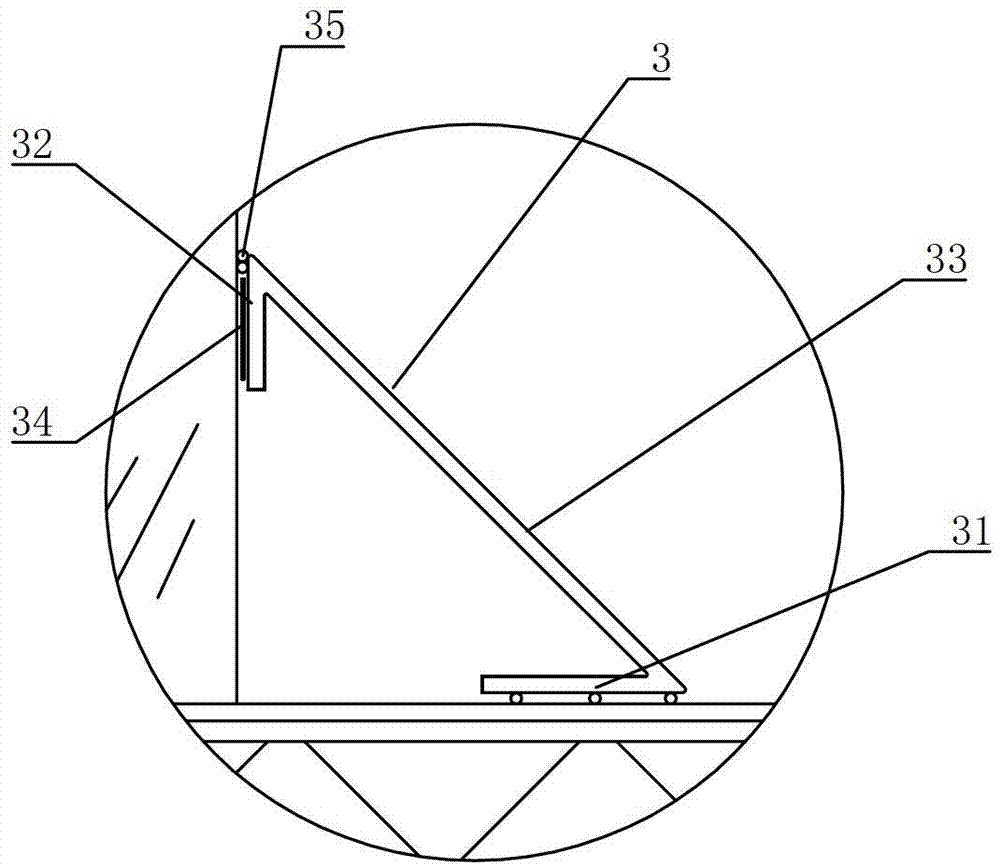

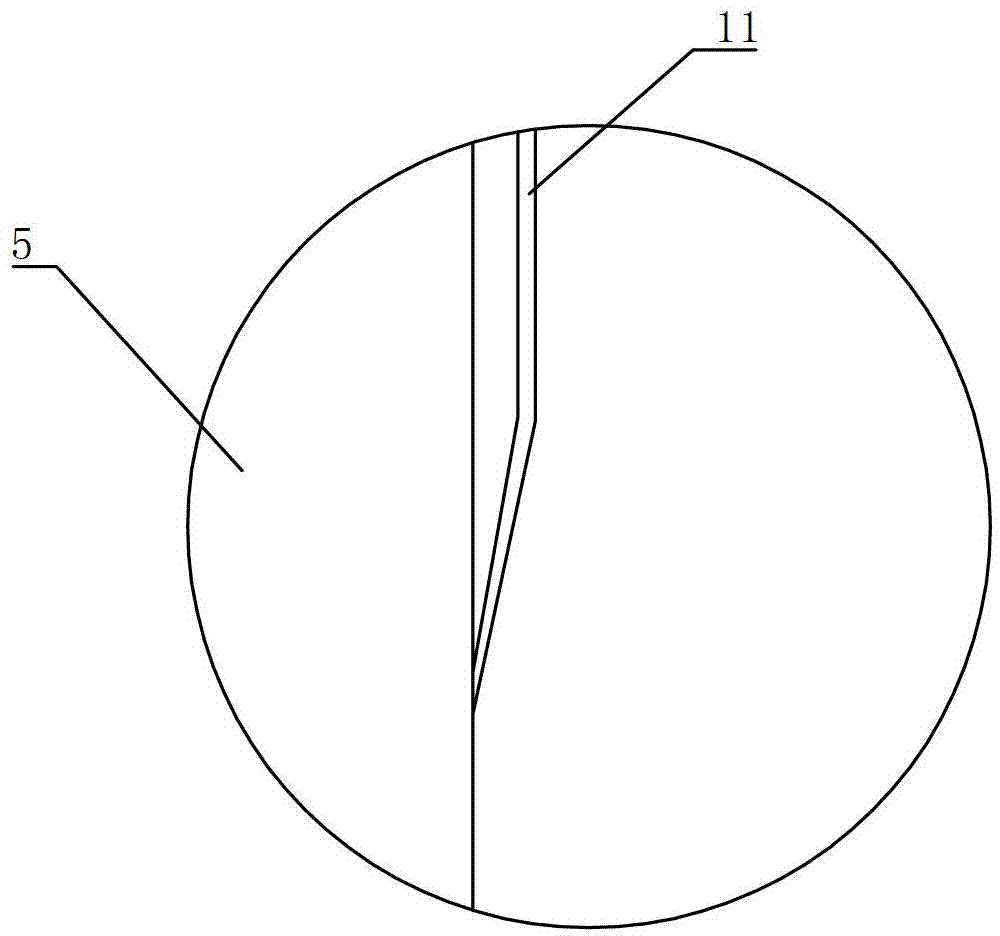

[0031] Such as Figure 1-Figure 7 As shown, a fireproof window in a clean room includes a window frame installed on the window hole of the wall 5, the window frame includes an integrally connected front sash 1 and an integrally connected rear sash 2, the main body of the front sash 1 Installed on the front of the window hole and contacting the edge of the window hole, the front window frame 1 is provided with a front covering edge 11, the front covering edge 11 is sealed and connected with the front of the wall body 5, the main body of the front window frame 1 and the front covering edge 11 Wrap the front end of the wall 5 on one side of the window hole, while the main body of the rear window frame 2 is installed at the rear of the window hole and contacts the edge of the window hole, and the rear window frame 2 and the rear window frame 2 are used to seal the connecting wall The rear edge 12 on the back side of the body 5 wraps the rear end of the wall body 5 on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com