Antiskid pile with hollow outer isosceles trapezoid cross section and in unequal interval arrangement

A technology of isosceles trapezoidal and cross-section, applied in sheet pile walls, excavation, construction, etc., can solve the problems of high cost, large pile body section, large concrete pouring volume, etc., to achieve enhanced structural strength, reduced quantity, and good sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

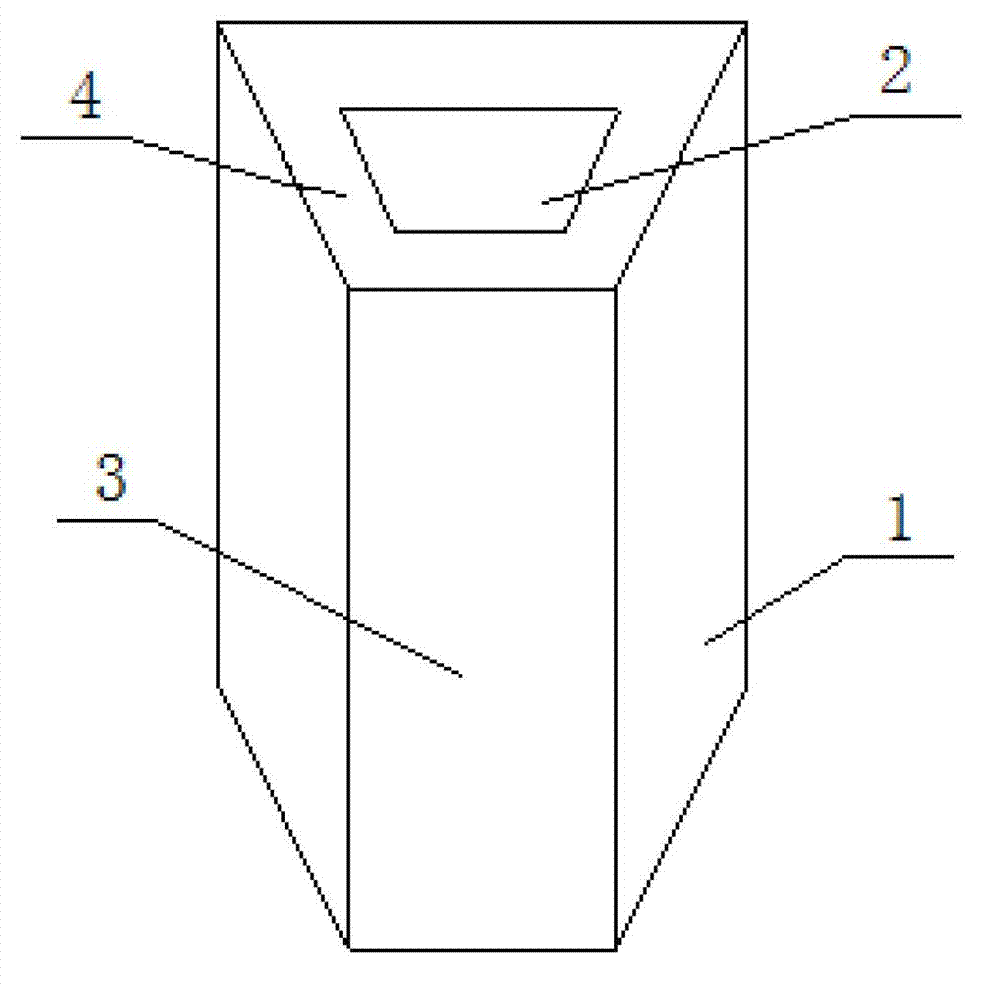

[0021] Embodiment 1: A kind of external isosceles trapezoidal hollow cross-section anti-slide pile 1 provided by the present invention, its structure is as follows figure 1 As shown, the poured reinforced concrete anti-slide pile has an outer isosceles trapezoidal hollow cross section 4, and the shape of the inner hollow hole 2 in the cross section is the same as that of the outer isosceles trapezoidal cross section.

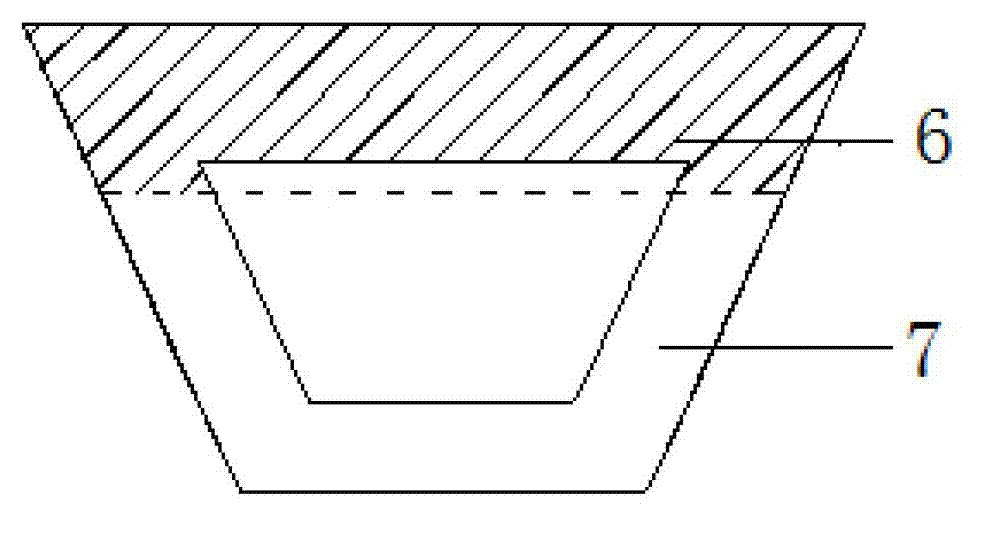

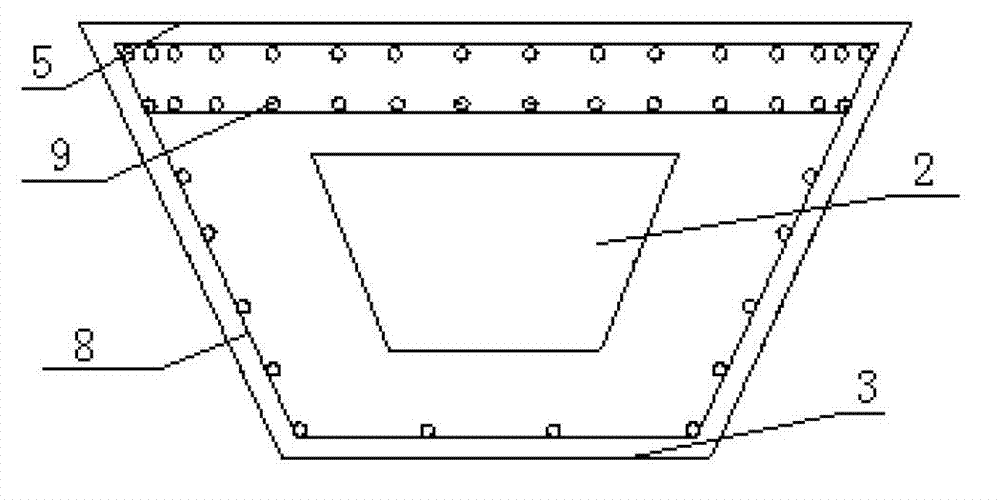

[0022] The stress distribution on the anti-slide pile cross section of the present invention is shown in figure 2 . One side of the longitudinal section of the long base of the outer isosceles trapezoid is used as the pile rear end 5 to bear the thrust 10 of the slope body, and the force on this side is tensile stress, which belongs to the tension area 6 . The rear end 5 of the pile is used as the arch foot of the soil arch behind the pile, and the slope body thrust 10 received at both ends is relatively large and complicated. One side of the longitudinal sec...

Embodiment 2

[0026] Embodiment 2: Apply the anti-slide pile 1 with outer isosceles trapezoidal hollow cross-section provided in Embodiment 1 of the present invention to carry out construction with unequal spacing. Because the engineering quantity of each pile of the anti-slide pile of the present invention is not large, the influence on the stability of the landslide body during construction is small, and the construction section of the anti-slide pile is small, and the construction can be carried out by means of mechanical construction. The specific construction steps are as follows:

[0027] ⑴ Level the site, measure and locate the center point where the anti-slide piles are located according to the design drawings, especially pay attention to the fact that the anti-slide piles are not equidistant, and the layout of the plane is characterized by "dense in the middle and sparse on both sides".

[0028] (2) Machines and tools are in place, including excavating equipment such as excavators,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com