Antiskid pile with T-shaped cross section

A technology of anti-sliding piles and cross-sections, which can be used in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of high cost and large amount of concrete pouring, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

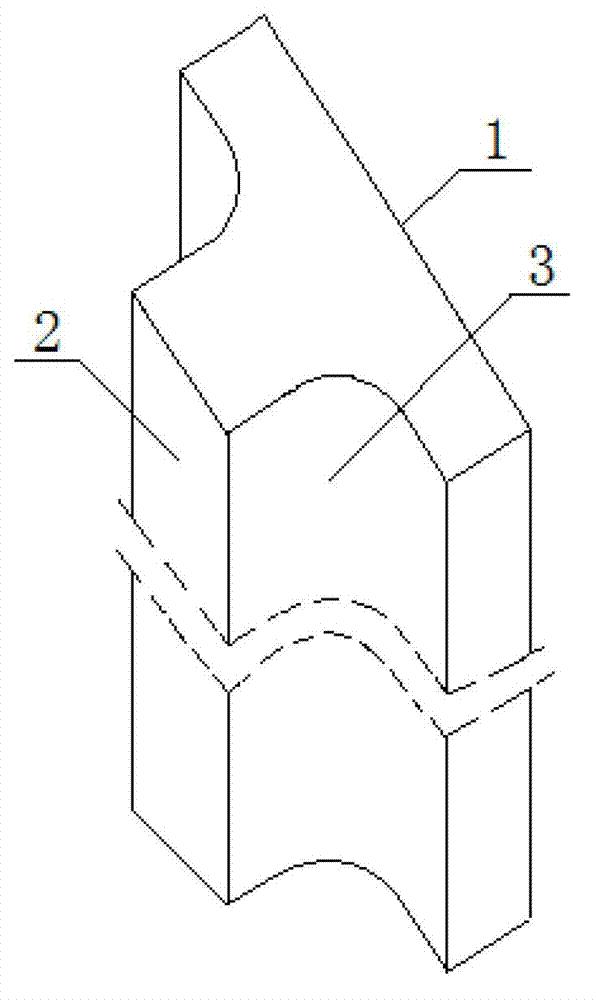

[0024] Embodiment 1: the anti-sliding pile 8 of a kind of T-shaped cross-section provided by the present invention, its structure is as follows figure 1 As shown, it is formed by pouring reinforced concrete. The cross-section of the poured reinforced concrete anti-slide pile is similar to a T shape. Between the pile front end 2 is an arc-shaped body part 3, and the transverse width of the pile rear end 1 is longer than the transverse width of the pile front end 2.

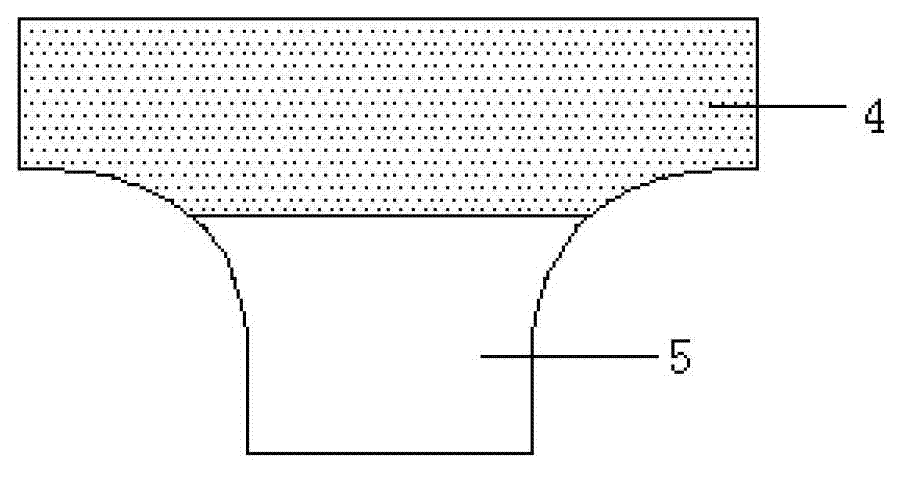

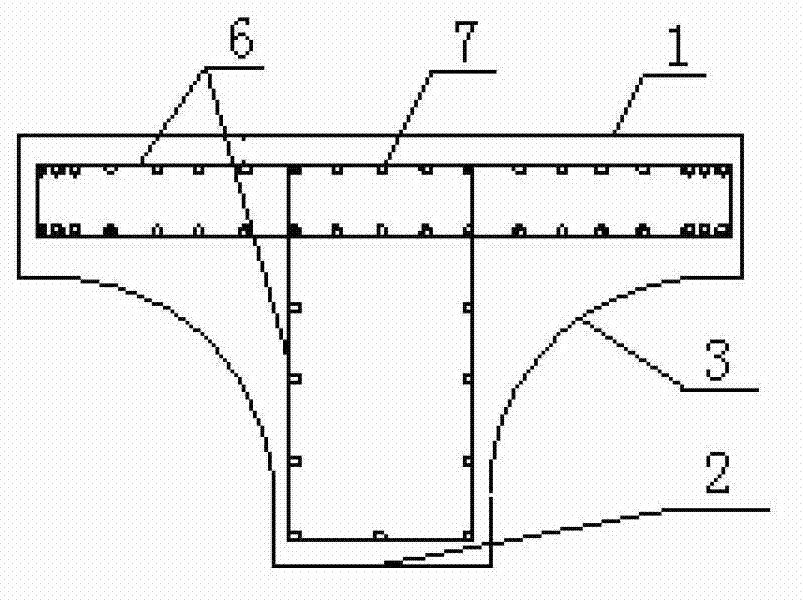

[0025] The stress distribution on the anti-slide pile cross section of the present invention is as follows: figure 2 As shown, the force on the rear end 1 of the anti-sliding pile is tensile stress, which belongs to the tension zone 4, and the force on the front end 2 of the pile and the front part of the arc body part 3 is mostly compressive stress, which belongs to the compression zone 5. In the reinforcement cage 6 installed inside the slide pile, denser steel bars 7 should be arranged at the pile rear end 1 o...

Embodiment 2

[0029] Embodiment 2: The anti-slide pile 8 with a T-shaped cross-section provided in Embodiment 1 of the present invention is used for construction. Since the construction section of the anti-slide pile is small, mechanical construction can be used for construction. The construction steps are as follows:

[0030] (1) Level the site, and measure and locate the center point of the anti-slide pile according to the design drawings. The distance between the centers of adjacent anti-slide piles is slightly larger than that of conventional rectangular anti-slide piles.

[0031] (2) Equipment in place, including digging equipment such as excavators, bulldozers, rock drills, safety equipment such as safety helmets, seat belts, and software, wall protection equipment such as formwork and support frames, electric welding machines, cranes, etc., steel bar processing and installation equipment, etc. Ready.

[0032] (3) Excavating holes, using excavators and rock drills to excavate the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com