Preparation method of energy-saving moisture-absorption-resisting xylooligosaccharide powder

A xylooligosaccharide and solution technology, applied in the field of functional sugar alcohols, can solve the problems of easy moisture absorption into lumps, moisture absorption and high energy consumption, and achieve strong moisture absorption resistance, easy storage, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

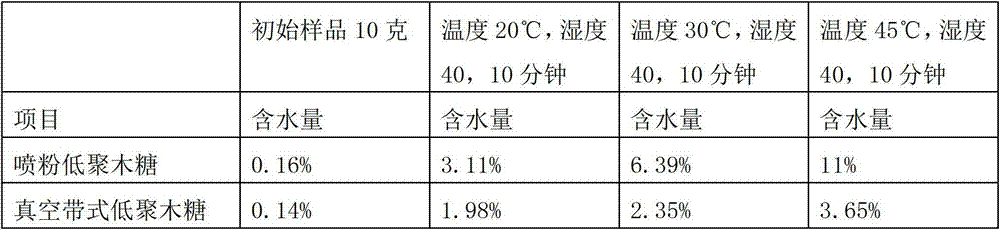

Embodiment 1

[0017] Embodiment 1: get the xylo-oligosaccharide syrup 1500kg that solution refraction 35%, xylo-oligosaccharide content are 96% in the dry matter, add gac by 5% of dry matter, stir and decolorize at 75 ℃, to remove the xylo-oligosaccharide in the solution Catalysts and other solid impurities, the stirring speed is 400 rpm, stirring for 30 minutes, after decolorization, filter to obtain the decolorization liquid; add plasma water to the decolorization liquid, control the refractive index at 44-48%, and then pass through the cation (001× 7) - Yin (D301) - Yin (D296) - Yang (001×7) resin to remove anions, cations, colloids, pigments and other substances in the xylooligosaccharide decolorization solution, purify them, and send them to the evaporator Evaporate to obtain 950 kg of xylo-oligosaccharide solution with a refraction of 55% and a conductance≤10 μS / cm;

[0018] Using a plunger metering pump, put the above xylooligosaccharide solution into a vacuum belt dryer (MTVBD50-4-5...

Embodiment 2

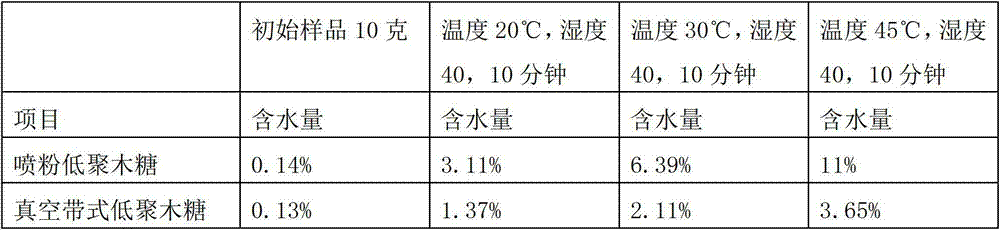

[0088] Embodiment 2: get the xylo-oligosaccharide syrup 1500kg that solution refraction 35%, xylo-oligosaccharide content are 96% in the dry matter, add gac by 5% of dry matter, stir and decolorize at 70 ℃, to remove the xylo-oligosaccharide in the solution Catalysts and other solid impurities, the stirring speed is 400 rpm, stirring for 25 minutes, after decolorization, filter to obtain the decolorization liquid; add plasma water to the decolorization liquid, control the refractive index at 44-48%, and then pass through the cation (001× 7) - Yin (D301) - Yin (D296) - Yang (001×7) resin, to remove anions, cations, colloids, pigments and other substances in the xylooligosaccharide decolorization solution, purify them, and send them to the evaporator Evaporate to obtain 870 kg of xylo-oligosaccharide solution with a refraction of 60% and a conductance≤10 μS / cm;

[0089] Use a plunger metering pump to inject the above-mentioned xylo-oligosaccharide solution into a vacuum belt dry...

Embodiment 3

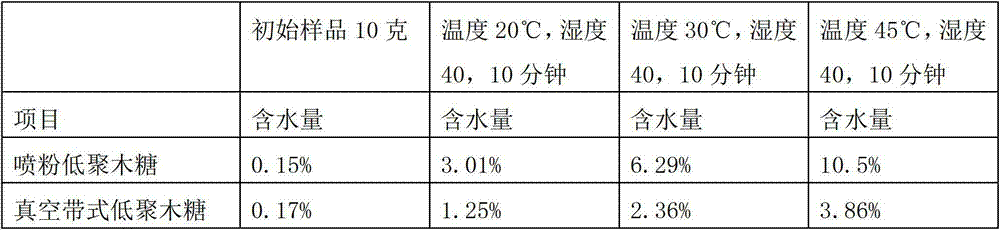

[0095] Embodiment 3: get solution refraction 50%, xylooligosaccharide content is 70% xylooligosaccharide syrup 1180kg in the dry matter, add gac by 5% of dry matter, stir and decolorize at 85 ℃, to remove the xylooligosaccharide in the solution Catalysts and other solid impurities, the stirring speed is 400 rpm, stirring for 30 minutes, after decolorization, filter to obtain the decolorization liquid; add plasma water to the decolorization liquid, control the refractive index at 44-48%, and then pass through the cation (001× 7) - Yin (D301) - Yin (D296) - Yang (001×7) resin, to remove anions, cations, colloids, pigments and other substances in the xylooligosaccharide decolorization solution, purify them, and send them to the evaporator Evaporate to obtain 805 kg of xylo-oligosaccharide solution with a refraction of 65% and a conductance≤10 μS / cm;

[0096] Use a plunger vacuum pump to pump the above xylooligosaccharide solution into a vacuum belt dryer, so that the syrup is eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com