Mixed culture method of microorganism containing oil

A mixed culture and microbial technology, applied in the biological field, can solve the problems of slow accumulation of microbial cells, high cost, and low oil content, and achieve the effects of enhanced mutual compatibility, reduced production costs, and increased accumulation content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

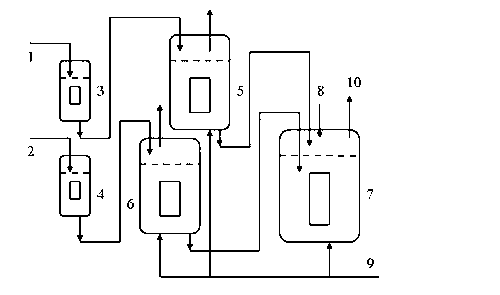

Embodiment 1

[0032] Rhodotorula viscosus and Chlorella were cultured separately in shake flasks using their respective media to obtain seed liquids with OD values of 10 and 6, respectively. The cultured Rhodotorula viscosus seed solution and Chlorella seed solution were respectively inserted into 10L bioreactors according to the inoculum volume (V / V) of 10%, and mixed culture medium was added to expand the culture. The specific culture conditions are as follows: Fermentation temperature is 30°C, ventilation volume (air) is 0.4 vvm, stirring speed is 200 rpm, pH is 7.0, and the mass concentration of organic carbon source is 1.5%. When the OD value of the fermentation broth was 2.0, the two fermentation broths were transferred to a 20L photobioreactor for mixed culture. The culture conditions were the same as those of the expanded culture, and the fermentation process was completed by continuing to culture for 5 days. Collect microbial cells, measure the dry weight and oil content, and obt...

Embodiment 2

[0034] When it is detected that the OD value of the Rhodotorula viscosus fermented liquid of expanded culture is 5.0, and when the OD value of the Chlorella fermented liquid is 10.0, the two fermented liquids are transferred to a 20L photobioreactor for mixed culture, and all the other conditions are the same as in Example 1. . Collect microbial cells, measure the dry weight and oil content, and obtain the harvested oil; measure the consumption of organic carbon sources, and calculate the carbon oil conversion rate index according to the amount of organic carbon sources consumed during the cultivation process.

Embodiment 3

[0036]When it is detected that the OD value of the Rhodotorula viscosus fermented liquid of the expanded culture is 10.0, and when the OD value of the Chlorella fermented liquid is 2.0, the two fermented liquids are transferred to a 20L photobioreactor for mixed culture, and all the other conditions are the same as in Example 1. . Collect microbial cells, measure the dry weight and oil content, and obtain the harvested oil; measure the consumption of organic carbon sources, and calculate the carbon oil conversion rate index according to the amount of organic carbon sources consumed during the cultivation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com