Continuous cracking process of waste rubber and device thereof

A waste rubber and equipment technology, which is applied in the continuous cracking process of waste rubber and the equipment field for realizing the process, can solve the problems of low oil yield, increased production energy consumption, incomplete cracking, etc., and achieve low sulfur content and low oil content , reduce production energy consumption, and avoid internal coking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

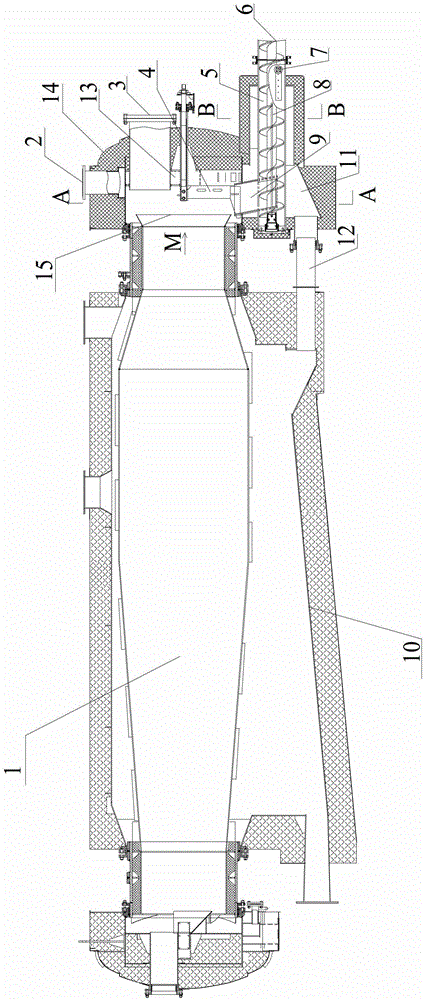

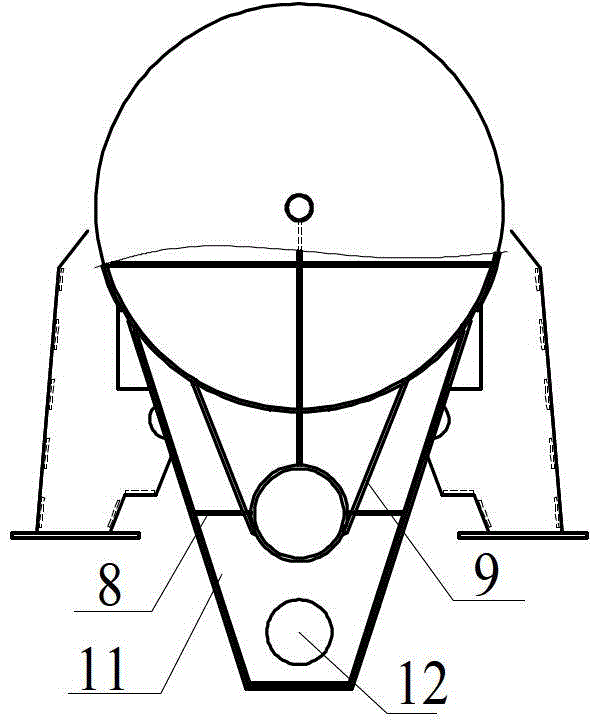

[0027] A continuous cracking process for waste rubber, including the following process: the pretreated waste rubber block first undergoes primary cracking at 380°C, and the oil and gas produced after the primary cracking is discharged from the oil and gas outlet; the solid product obtained by the primary cracking is directly Enter the secondary cracking process for secondary cracking, the temperature of the secondary cracking is 450°C, the carbon black after the secondary cracking is discharged from the carbon black outlet, and the oil and gas generated by the secondary cracking are returned to the primary cracking chamber again, and the same level The oil and gas produced during the fracturing process are discharged together.

Embodiment 2

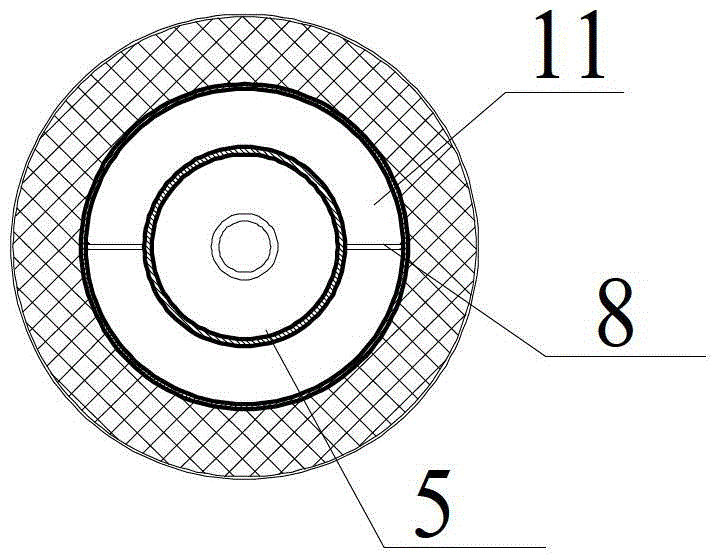

[0029] A continuous cracking process of waste rubber, including the following process: the pretreated waste rubber block first undergoes primary cracking at 410°C, and the oil and gas generated after the primary cracking is completed are discharged from the oil and gas outlet; the solid product obtained from the primary cracking is directly Enter the secondary cracking process for secondary cracking, and pass water vapor along the opposite direction of solid material movement during the secondary cracking process of solid products. The temperature of the secondary cracking is 500 ° C, and the carbon black after the secondary cracking The black outlet is discharged, and the oil and gas produced by the secondary cracking process, the gas generated by the reaction of water vapor and the sulfur in the carbon black, and the oil on the surface of the carbon black are all returned to the primary cracking chamber, and the oil and gas generated during the same primary cracking process ar...

Embodiment 3

[0031] A continuous cracking process for waste rubber, including the following process: the pretreated waste rubber block first undergoes primary cracking at 400°C, and the oil and gas generated after the primary cracking is completed are discharged from the oil and gas outlet; the solid product obtained by the primary cracking is directly Enter the secondary cracking process for secondary cracking, and pass water vapor along the opposite direction of solid material movement during the secondary cracking process of solid products. The temperature of the secondary cracking is 480 ° C. After the secondary cracking, the carbon black The black is discharged from the outlet, and the gas generated by the reaction of the oil gas and water vapor in the secondary cracking with the sulfur in the carbon black and the oil on the surface of the carbon black are all returned to the primary cracking chamber, and together with the cracked gas generated in the same primary cracking process disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com