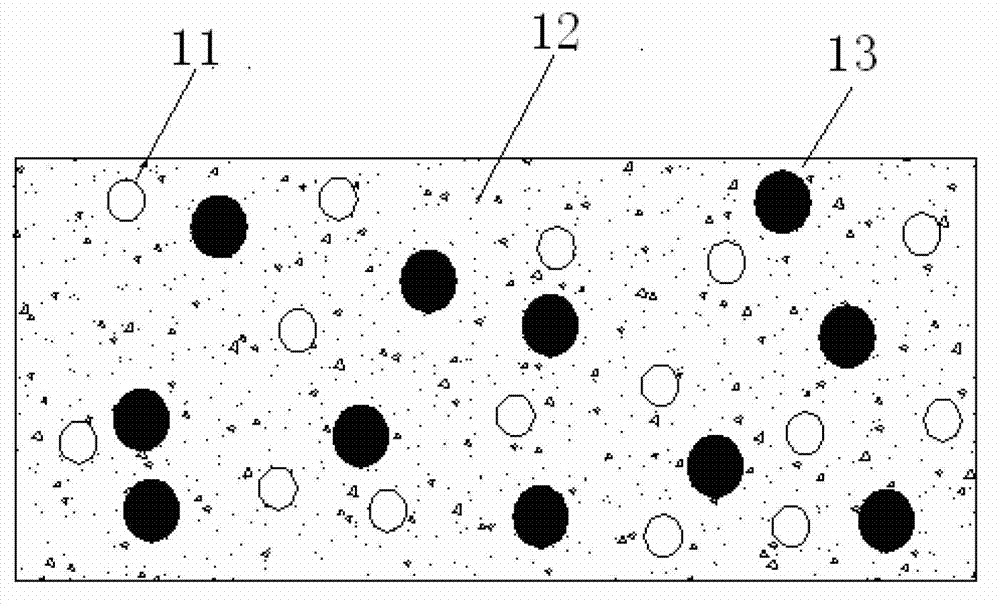

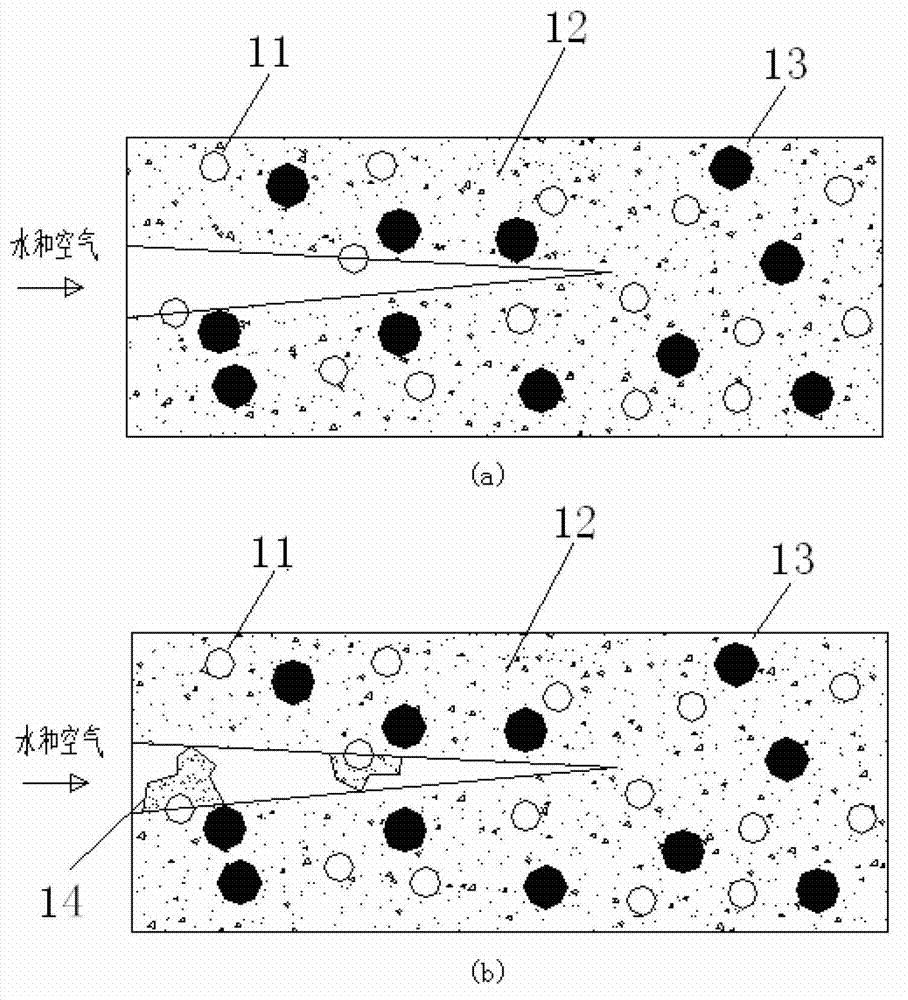

Compound capsule underground structure concrete self-repairing system provided with aerobic microorganisms inside

A composite capsule and underground structure technology, applied in the field of concrete engineering, can solve problems such as insufficient storage time of restoration agents, insufficient sealing performance, and no theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

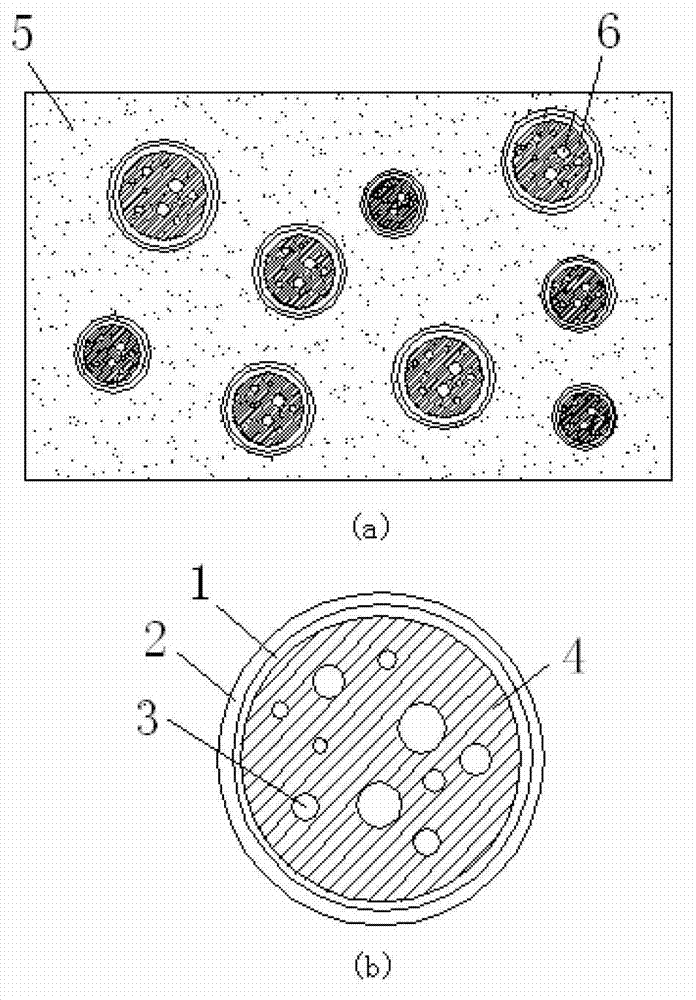

[0098] Microbial composite capsules were prepared by interfacial polymerization. First configure the culture medium containing alkalophilic bacillus, the concentration of alkalophilic bacillus is 10 9 cell / ml, add 6g / L sodium citrate, 5g / L peptone, 3g / L yeast extract, 0.2g / L ammonium chloride, 0.02g / L potassium dihydrogen phosphate, 0.225g / L calcium chloride, 0.2 g / L potassium chloride, 0.2g / L magnesium chloride hexahydrate.

[0099] At 30°C, 5g TDI (toluene diisocyanate), 1g PPG2000 (polypropylene glycol 2000) and different quality media were added to 200mL distilled water containing 1.5g emulsifier SMA (styrene maleic anhydride copolymer) and heated at 4500r / Continue to stir for 10min at the speed of min-5000r / min, and continue to stir for 5min at 400r / min-800r / min, then slowly add 20ml of aqueous solution containing 2gDETA (diethylenetriamine) to the above system, keep the reaction for 30min, continue Raise the temperature to 60°C and keep it warm for 3 hours to promote ...

Embodiment 2

[0104] Referring to the method in Example 1, experiments were carried out on Bacillus subtilis, Azotobacter sp., nitrifying bacteria, and Brevibacterium flavum. The specific experimental conditions are shown in Table 1.

[0105] Table 1

[0106]

[0107] Refer to the steps of Example 1 for the compound capsules of the obtained Bacillus subtilis, nitrogen-fixing bacteria, nitrifying bacteria, and Brevibacterium flavum to prepare the corresponding concrete containing microbial compound capsules, and then carry out the same initial damage test as in Example 1 After observing the experimental results, it was found that calcite crystals were produced on the surface of the concrete cracks in the composite capsules of the four microorganisms, and the longer the curing time, the more calcite crystals. The greater the initial damage, the more calcite crystals.

[0108] It can be seen that after the microbial composite capsule in the concrete is broken, the calcite precipitation gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com