Lengthened glass cutter

A glass knife and knife bar technology, which is used in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of parallel line deviation, inconvenient operation, large line straightness error, etc., and achieves increased length and convenient operation. , the effect of accurate parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

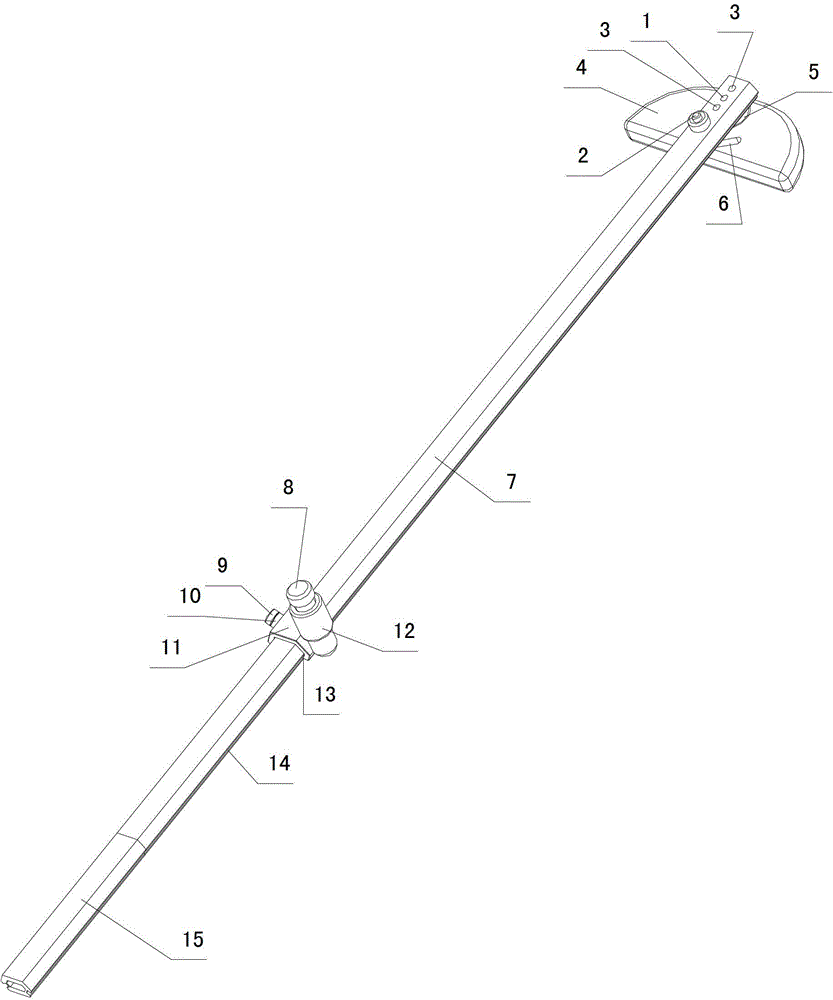

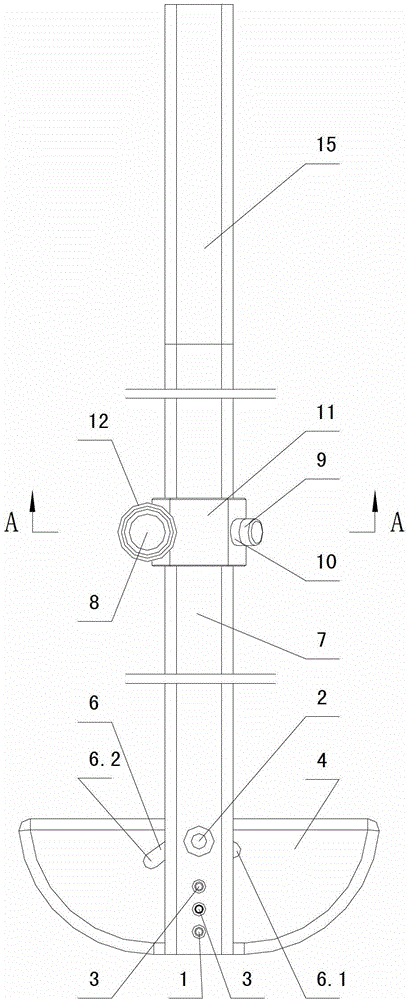

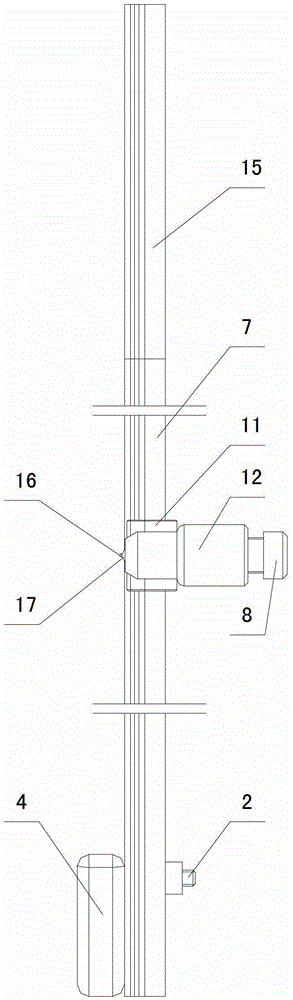

[0032] Depend on Figure 1 to Figure 8 The shown schematic diagram of the structure of the extended glass knife of the present invention can be seen that it includes a cutter head 16 and a knife bar 17, and the said knife head 16 is located at one end of the knife bar 17, and it also includes a backing plate 4, a ruler 7 and a slide device, one end of the ruler 7 is rotatably connected to the backing plate 4 and locked by a locking device, the sliding device is slidably connected to the ruler 7, and the knife bar 17 is connected to the sliding device and is perpendicular to the ruler 7 and abuts against the A plane on the glass surface; the end of the ruler 7 away from the backing plate 4 is detachably connected with an extension ruler 15 .

[0033] Described ruler 7 inside is hollow along the length direction, and extension ruler 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com