Carrousel oxidation ditch process optimized control method

A process optimization, oxidation ditch technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of limited experimental plan, high cost, high cost, etc., to save Labor and time costs, reducing operating costs, and saving computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with specific examples, but the present invention is not limited to the following examples.

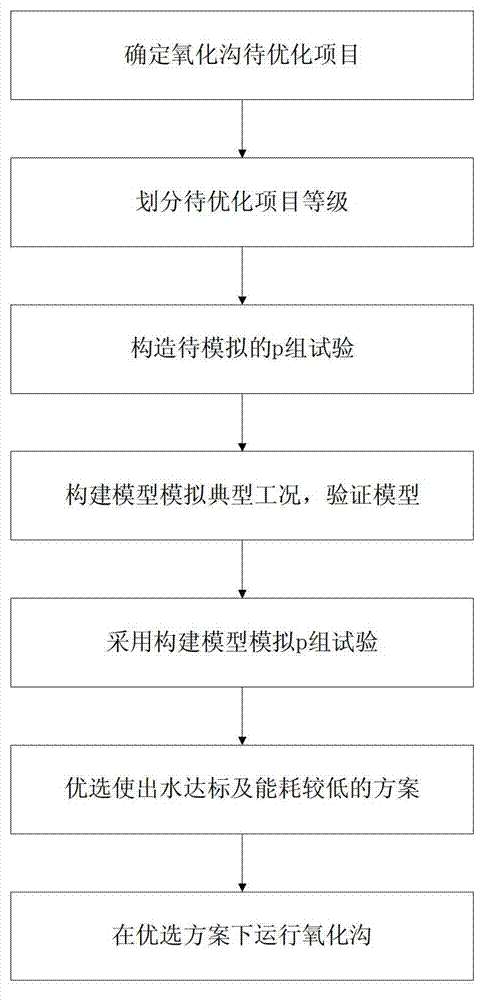

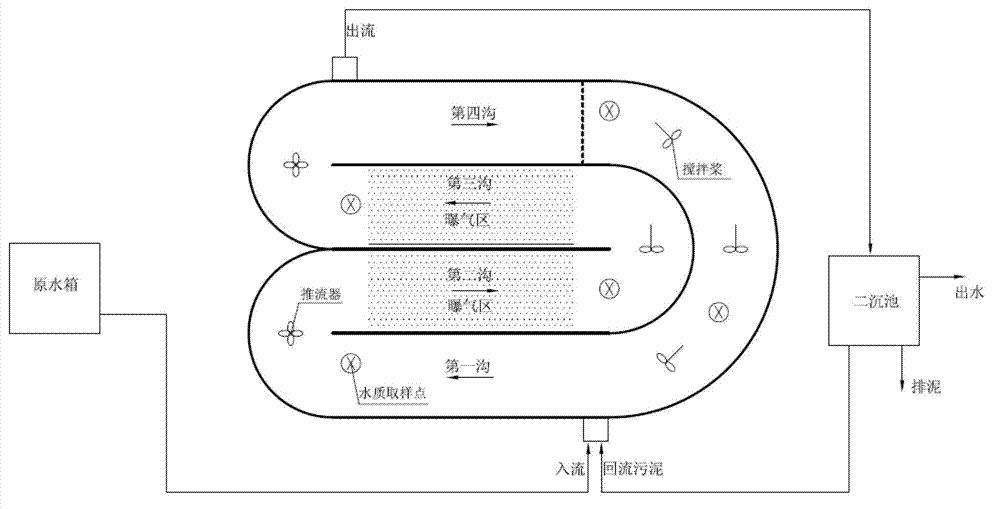

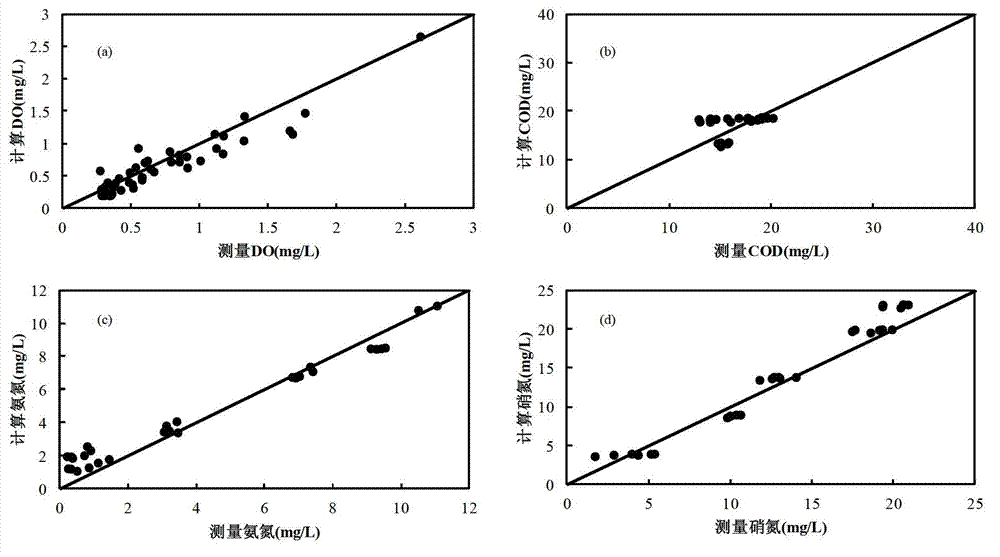

[0025] figure 1 It is a schematic flow chart of optimization and regulation of a Canusel oxidation ditch process of the present invention. The simulation object of this example is a four-corridor Kanusel oxidation ditch at the pilot scale, such as figure 2 shown. The total length of the oxidation ditch is 2.2m, the width is 1.4m, the effective water depth is 0.5m, and the effective volume is 1.4m 3 ; The length of the straight ditch is 1.05m, the radii of the big and small bends are 0.35m and 0.7m respectively, and the width of the single ditch is 0.35m. The water inlet section of the oxidation ditch is a rectangle with a length of 200mm and a width of 50mm; 3 The flow rate per hour flows into the oxidation ditch, and the water quality indicators of the sewage flowing into the oxidation ditch are: COD=250mg / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com