Method for preparing small solid carbon ball and carbon ball prepared thereby

A small-scale, solid technology that can be used in carbon preparation/purification, nanotechnology for materials and surface science, nanotechnology, etc., and can solve problems such as low specific surface area, confinement of carbon spheres, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

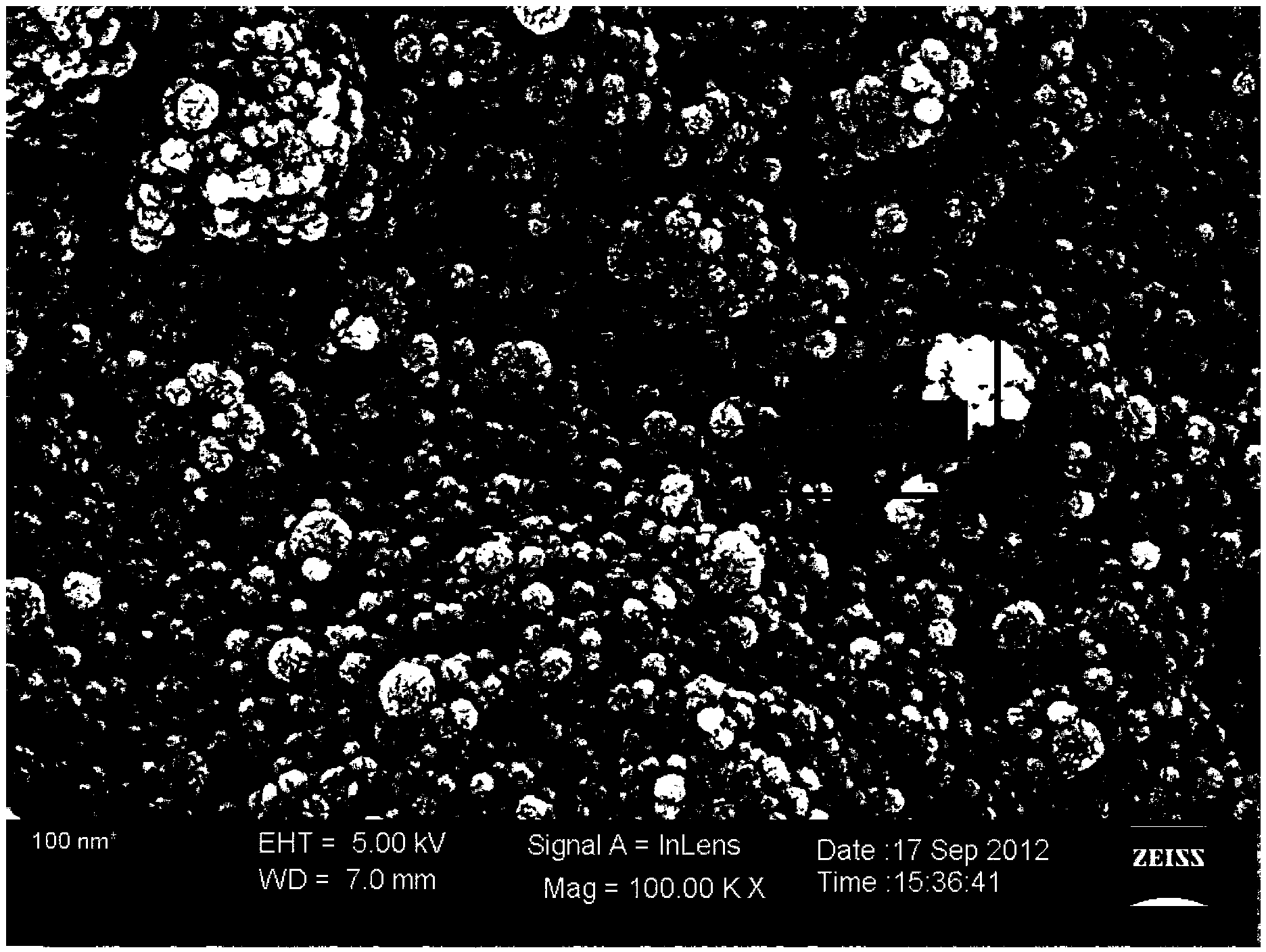

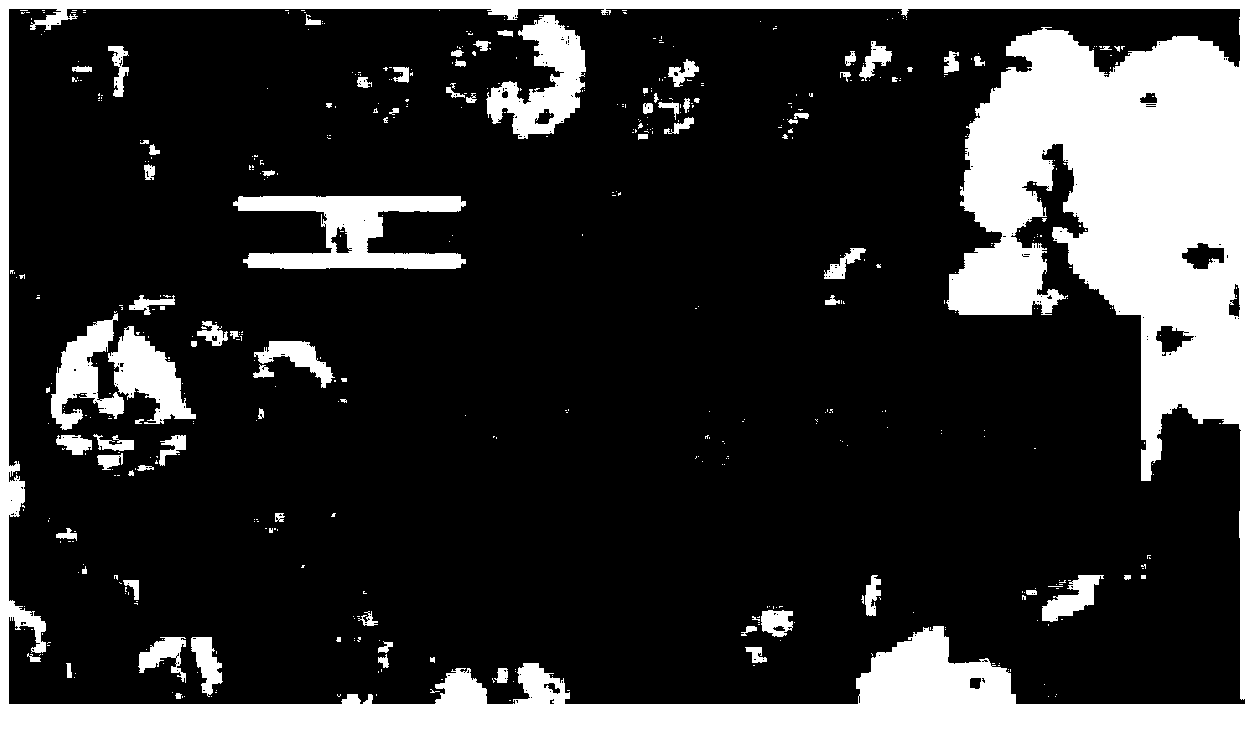

[0027] Add 6g of glucose and 45ml of deionized water into a 50ml beaker, stir to dissolve. Then add 1 g of polymeric ionic liquid PIL-a (shown in the structure below), and dissolve in the above glucose solution. The resulting solution was transferred to a reaction kettle, heated to 150°C, and reacted for 16 hours. After the reaction is finished, the product is washed with distilled water, then suction filtered, and the small-sized carbon spheres are obtained after drying. The scanning electron microscope image of the obtained carbon spheres is shown in figure 1 and figure 2 shown. According to the results of electron microscopy, the size of carbon spheres is in the range of 30-55nm. figure 2 The distance between the two straight lines in is 32.33 nm, which is the diameter of one of the representative carbon spheres prepared.

[0028] The preparation steps of PIL-a are as follows: monomer 1-vinyl-3-propyl imidazole chloride 8g, free radical initiator azobisisobutyronitri...

Embodiment 2

[0031] Add 10g of sucrose and 50ml of deionized water into a 50ml beaker, stir to dissolve. Then add 1 g of polymeric ionic liquid PIL-b (shown in the structure below), and dissolve in the above sucrose solution.

[0032]

[0033] The resulting solution was transferred to a reaction kettle, heated to 230 degrees, and reacted for 32 hours. After the reaction is finished, the product is washed with distilled water, then suction filtered, and the small-sized carbon spheres are obtained after drying. The size of the carbon spheres was analyzed from the electron microscope results in the range of 34-66nm.

Embodiment 3

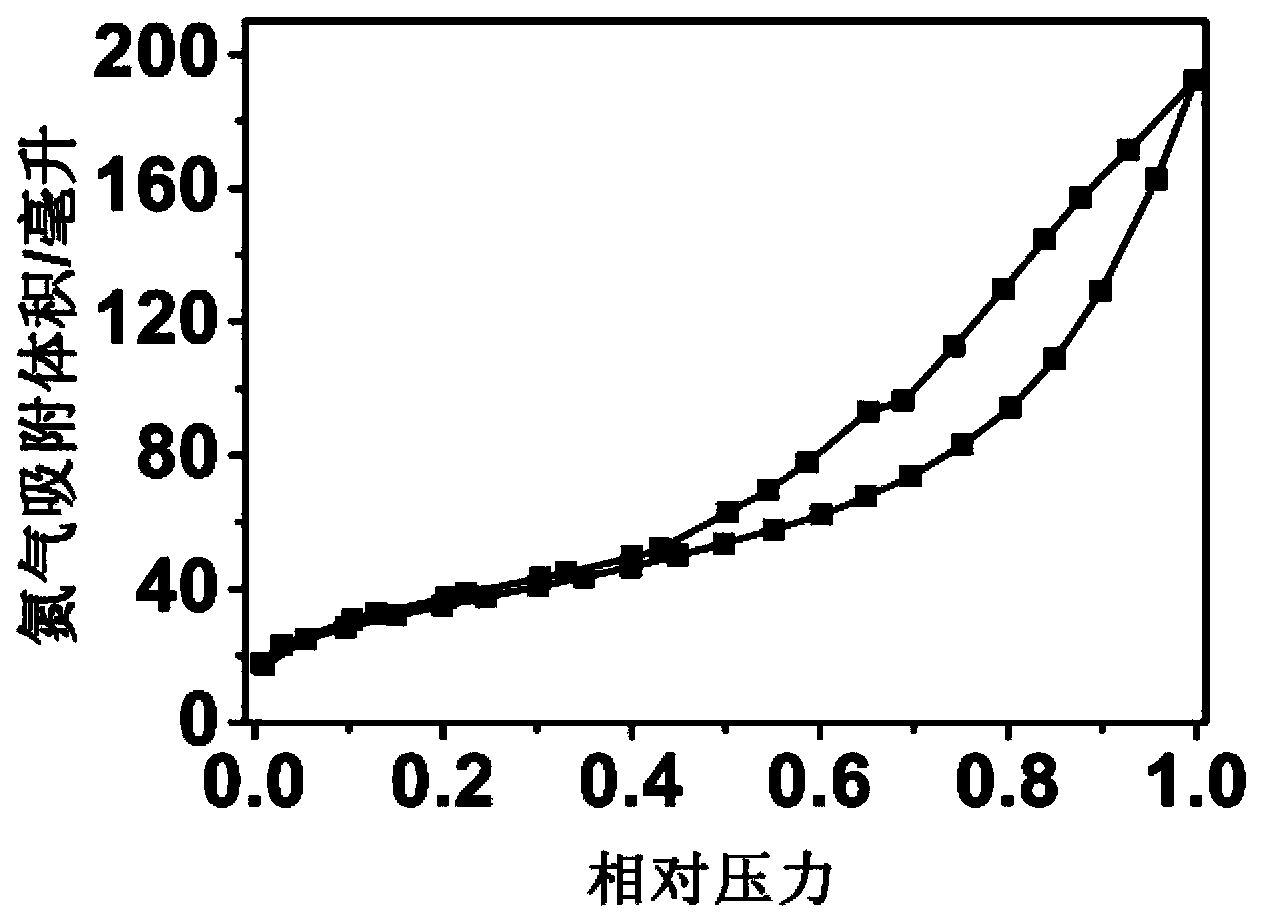

[0035] Add 6g of glucose and 45ml of deionized water into a 50ml beaker, stir to dissolve. Then 1 g of polymeric ionic liquid PIL-b (same as Example 2) was added and dissolved in the above glucose solution. The resulting solution was transferred to a reaction kettle, heated to 150°C, and reacted for 24 hours. After the reaction is finished, the product is washed with distilled water, then suction filtered, and the small-sized carbon spheres are obtained after drying. The size of the carbon spheres was analyzed from the electron microscope results in the range of 45-64nm. The low-temperature nitrogen adsorption test shows that the BET specific surface area of the obtained small-sized carbon spheres can reach 129m 2 / g, see below image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com