Clamping fixture

A fixture and the same technology, applied in the field of fixtures, can solve the problems of low work efficiency, complicated processing technology, time-consuming and money-consuming, etc., and achieve good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

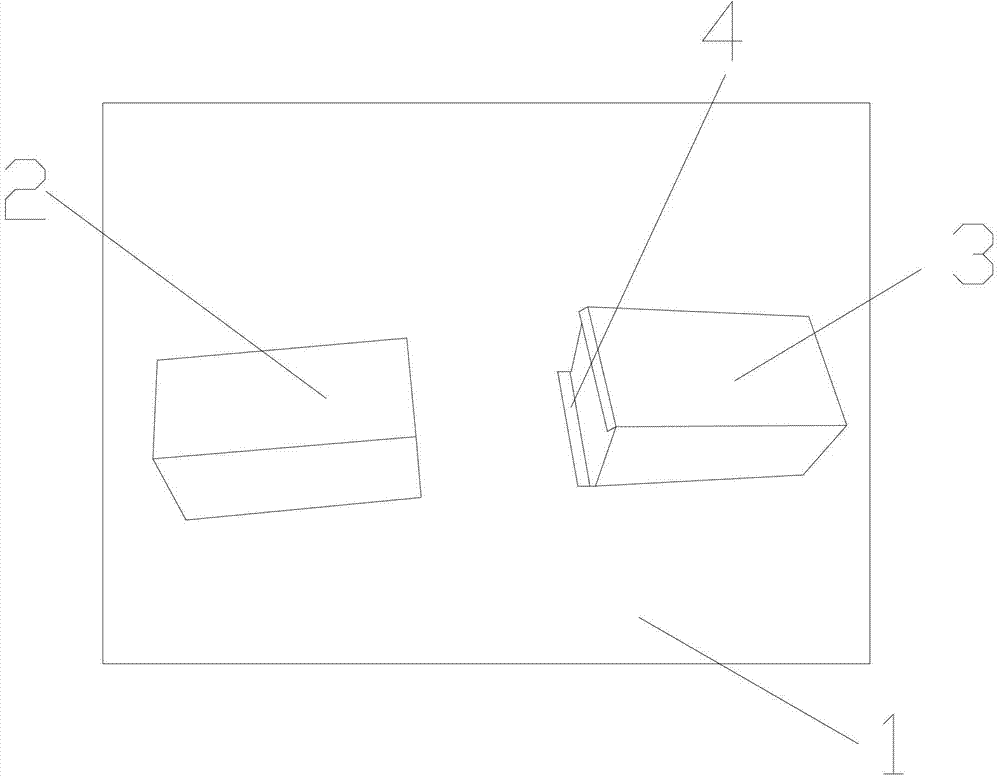

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] like figure 1 As shown, a clamping jig includes a square seat 1, a fixed claw 2 and a horizontally movable claw 3, the fixed claw 2 is arranged on the square seat 1, and a slideway 4 is arranged on the square seat 1, The bottom of the horizontally moving jaw 2 is inserted into the slideway 4, and can move horizontally along the slideway 4, the fixed jaw 2 and the horizontally moving jaw 3 are located on the same straight line, and the fixed jaw 2 and the horizontally moving jaw The bayonet openings of the jaws 3 are arranged oppositely, and the length of the horizontally movable jaw 3 is greater than that of the fixed jaw 2 .

[0011] In the present invention, the product is placed between the two jaws, the position of the fixed jaw 2 remains fixed, the horizontally movable jaw 3 can move forward along the slideway 4, and the bayonets of the fixed jaw 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com