Steel wire mesh netting machine for coal mine anchor rod supporting

A bolt support and steel wire mesh technology, applied in the mechanical field, can solve the problems of uncontrollable tension force, affecting the overall bearing capacity, affecting aesthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

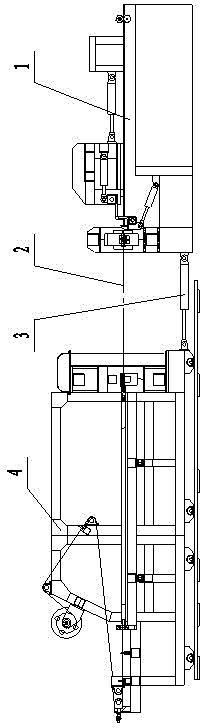

[0135] Example: figure 1 Shown, present embodiment comprises main frame 1 and follower 4, and main frame 1 is fixed on the foundation, and follower 4 moves back and forth on its own track, is connected with hydraulic cylinder 3 between two machines and pulls follower to move. All the meshes pass through the shuttle row of the main machine and the follower, and the hydraulic cylinder is used to push the follower to tension the mesh so that the mesh has tension.

[0136] The main machine is the mechanism for weaving the net, and the follower is the mechanism for unwinding and storing the mesh. Each working mechanism and each step of the network machine are automatically controlled by the PLC automatic control system.

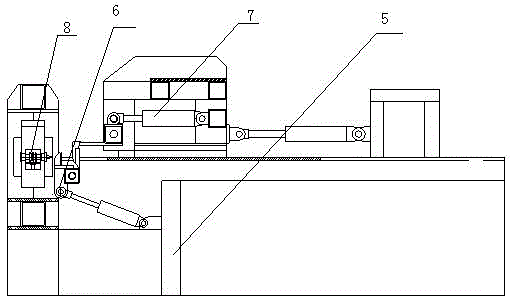

[0137] figure 2 As shown, the main frame 1 includes a main frame 5, a shuttle mechanism 7, a mesh comb mechanism 6, a net pulling mechanism 8, and a net pressing mechanism. The shuttle row mechanism 7 is arranged on the front of the net comb mechanism 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com