Beating sieve cleaning mechanism of peanut rotary drum grader

A technology of cleaning mechanism and classifier, which is applied in the direction of sieving, solid separation, grille, etc. It can solve the problems of rough surface, potholes, and screen blockage of peanut pods, and achieve high cleaning rate and low crushing rate of peanut pods. , Improve the effect of speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

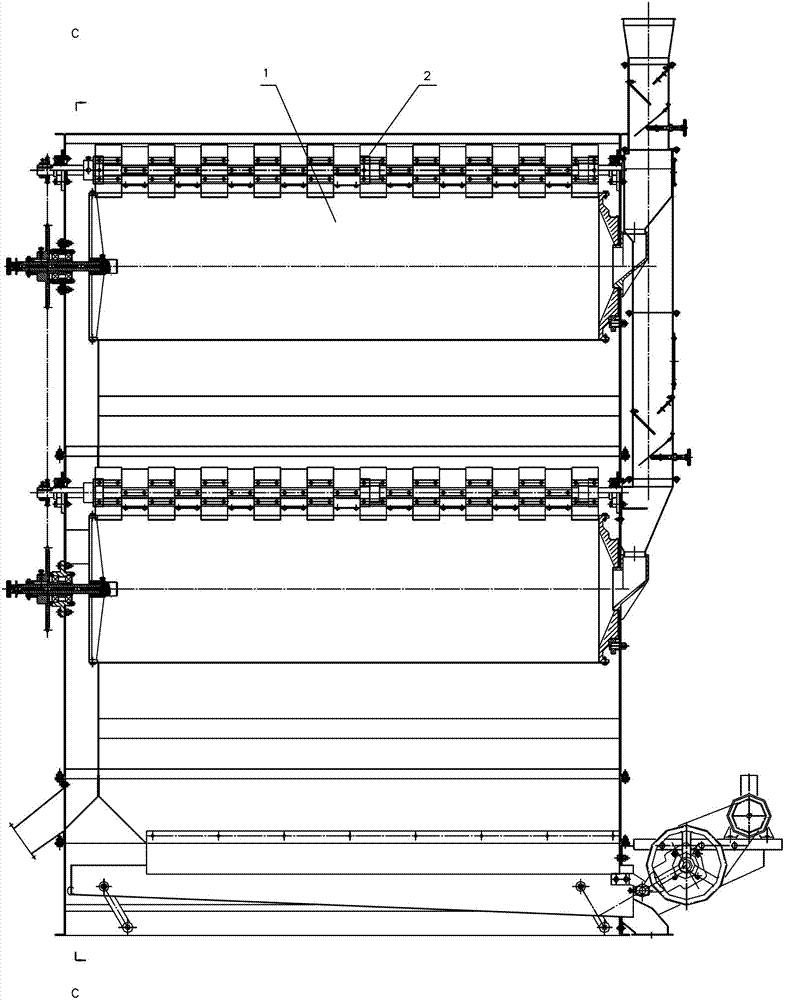

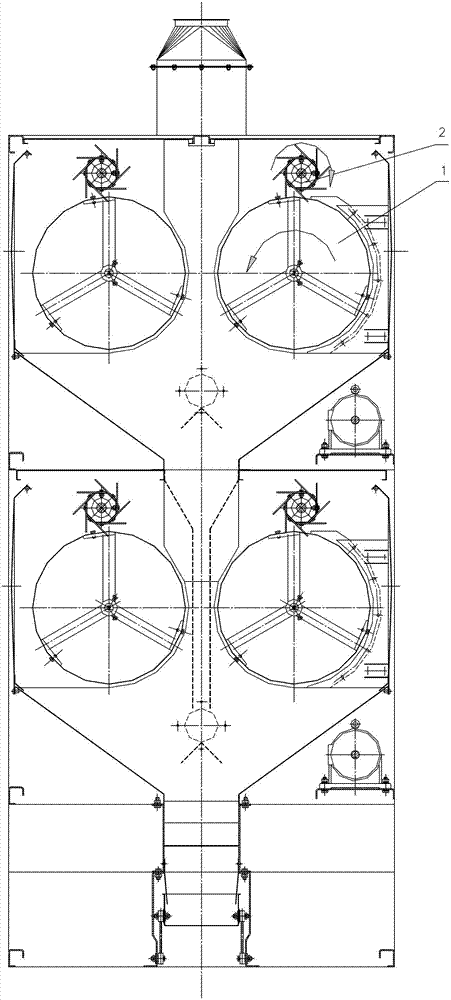

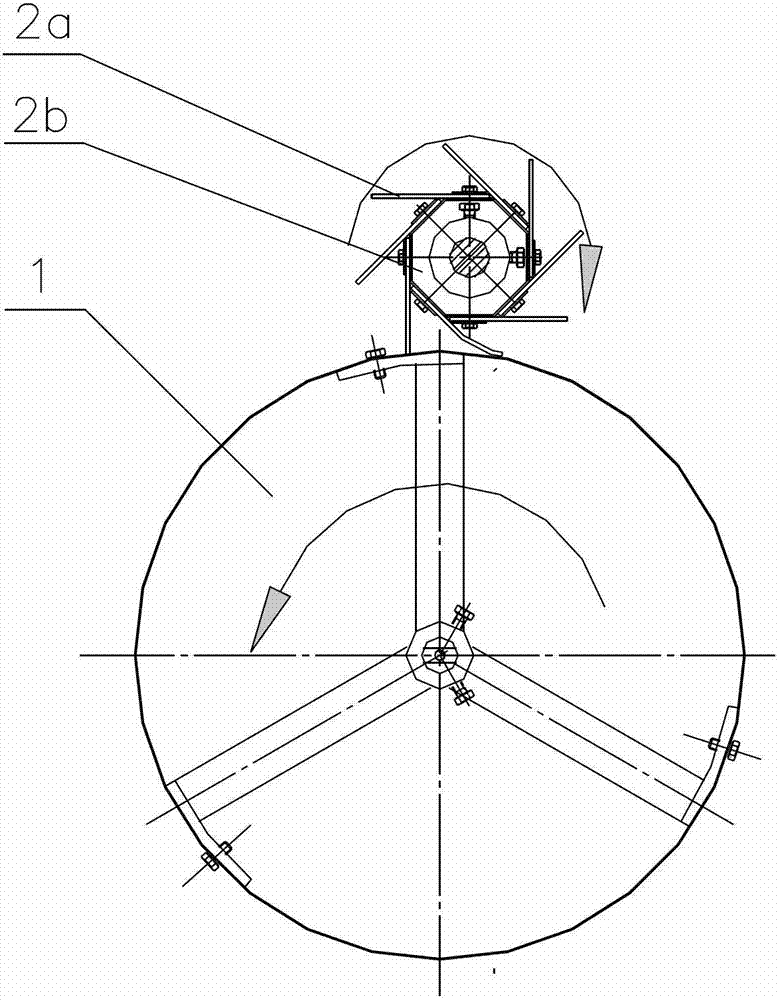

[0032] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] The beating and cleaning mechanism of the peanut roller classifier includes the grading roller 1 of the peanut roller classifier. On the outer side of the grading roller 1, a beating shaft 2b is arranged parallel to the axis of the grading roller 1. The beating shaft 2b is arranged along the length of the shaft. A number of beating rollers 2; the beating rollers 2 are wind wheel structures, that is, several rectangular beating pieces 2a are fixed in a cantilever manner on the outer peripheral wall of beating shaft 2b, beating piece 2a is a soft elastic plate, and one end of beating piece 2a is fixed On the outer wall of the beating shaft 2b, the beating sheet 2a forms an included angle with the radial line fixed on the outer wall of the beating shaft 2b, and the angle is positive or negative 90 to 150 degrees; when the beating roller 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com