TiO2 photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high cost and difficult preparation of activated carbon fibers, and achieve increased contact reaction opportunities, combined with The effect of high intensity and strong enrichment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

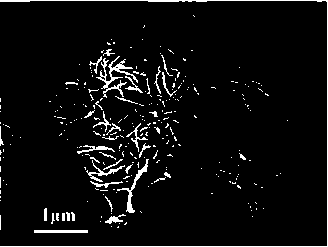

Image

Examples

Embodiment 1

[0033] Porous carbon materials were prepared using glucose as carbon precursor. Glucose was dissolved in distilled water successively, so that the concentration of the glucose aqueous solution was 15 wt%, and the solution was shaken. Immerse 1 gram of MCM-22 zeolite with a particle size of about 3 μm in 20 ml of glucose solution for 20 minutes, then pour out the excess liquid, and use filter paper to suck up the solution that cannot be poured out. The mixture was placed in an oven at 65°C for 3 hours, then slowly raised to 130°C for 5 hours. During the heating and constant temperature process, with the evaporation of water, the colorless glucose solution gradually polymerized and carbonized, and finally turned into a black C / MCM-22 complex. To increase the filling rate, repeat the above steps 3 times. Finally the complex was placed in N 2Under the protection of the atmosphere, the temperature was raised to 800° C. and kept at a constant temperature for 12 hours. After natu...

Embodiment 2

[0037] Porous carbon materials were prepared by using water-soluble phenolic resin as carbon precursor. A water-soluble phenolic resin solution with a concentration of 7wt% was prepared, and 1 g of calcined MCM-22 zeolite with a particle size of about 5 μm was immersed in 20 mL of the water-soluble phenolic resin solution. After the adsorption was saturated, the excess liquid was poured out. The mixture was placed in an oven at a constant temperature of 80°C for 2 hours, then slowly raised to 150°C and kept at a constant temperature for 2 hours. To increase the filling rate, repeat the above steps 3 times. Finally the complex was placed in N 2 Under the atmosphere, the temperature was raised to 900° C., and the temperature was kept constant for 6 hours. After naturally cooling to room temperature, the carbonized material was soaked in 20wt% HF solution for 24 hours. Then wash with distilled water and filter until the pH value of the washing solution is close to neutral. Fi...

Embodiment 3

[0041] Porous carbon was prepared from furfuryl alcohol. Disperse 3mL of furfuryl alcohol evenly in 10mL of ethanol, impregnate 1 gram of calcined MCM-22 zeolite with a particle size of about 10μm in 20mL of the above solution, after the adsorption is saturated, then pour out the excess liquid. The mixture was placed in an oven and the temperature was directly raised to 100° C. for 6 hours without segmenting. To increase the filling rate, repeat the above steps once. Finally the complex was placed in N 2 Under the atmosphere, the temperature was raised to 1000° C., and the temperature was kept constant for 1 hour. After the complex was naturally cooled to room temperature, the complex was soaked with 30wt% NaOH solution to remove MCM-22, and then washed with distilled water and filtered until the pH of the washing solution was close to neutral. Finally, the sample was dried to obtain a porous carbon material, named C3, and the relevant properties are listed in Table 1.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com