Novel cubic combination hydraulic machine

A combined structure and six-sided roof technology, which is applied in the field of diamond hydraulic presses, can solve problems such as the inability of man and machine to coordinate, and the inability to adapt to the operation requirements of operators and maintenance personnel, and achieve the effect of facilitating maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

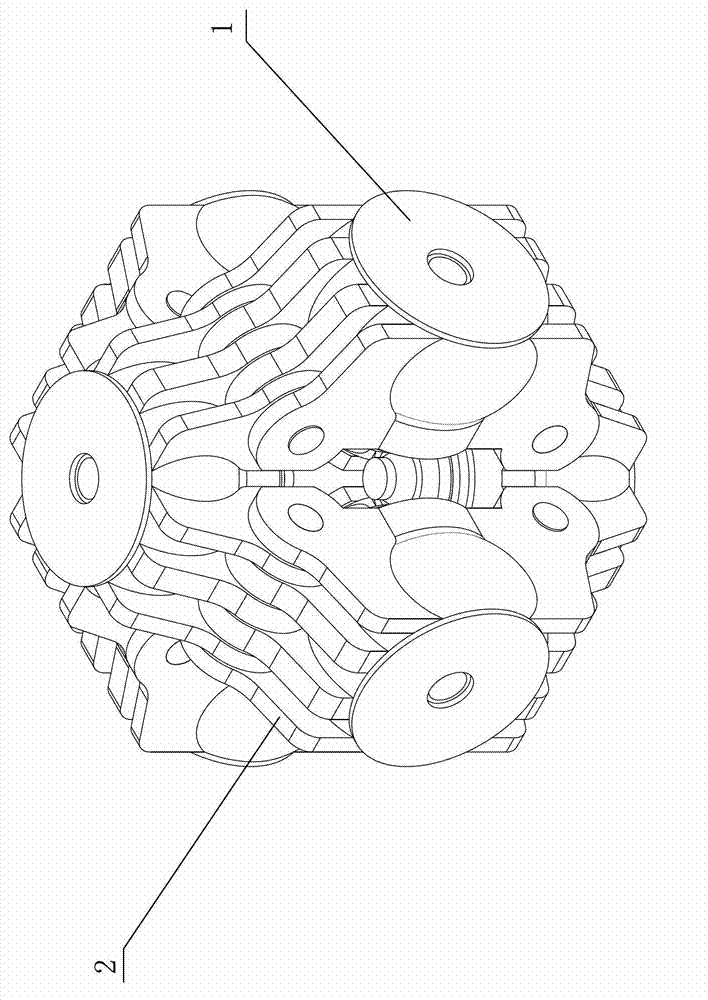

[0015] The upper, lower, front, rear, left and right six hinged beams 1 of the novel six-sided roof combined structure hydraulic press of the present invention are spatially symmetrically arranged.

[0016] The upper and lower hinge beams 1 have respectively downward and upward front, rear, left and right four groups of longitudinal connecting lugs 2, and each group of connecting lugs 2 is three pieces; the front, rear, left and right Hinge beam 1 has two groups of longitudinal connecting lugs 2 up and down without transverse connecting lugs 2, and each group of connecting lugs 2 is four pieces, as figure 1 shown.

[0017] The connecting lugs 2 of the upper and lower hinged beams 1 are hinged with the connecting lugs 2 of the front, rear, left and right hinged beams 1, and the upper and lower hinged beams 1 and the middle hinged beam 1 (front or rear) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com