High-efficiency internal circulation evaporation separation tower

A technology of internal circulation and separation tower, applied in the field of hydrochloric acid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

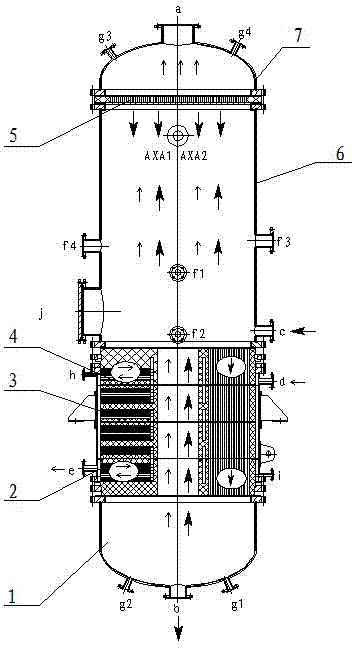

[0018] The present invention will be further described below using the accompanying drawings and examples.

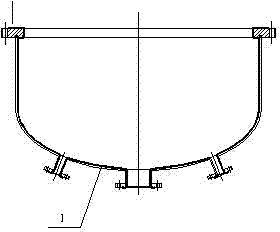

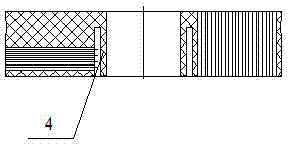

[0019] refer to Figure 1-11 , The high-efficiency internal circulation evaporation separation tower of the present invention includes a cylinder body 6, and the cylinder body 6 is composed of an upper cylinder and a lower cylinder. The upper end of the cylinder body 6 is fixedly connected with the upper head 7 , and the lower end of the cylinder body 6 is fixedly connected with the separator 1 . There are at least three circulation heating blocks accumulatively installed in the barrel 6, which are respectively the accumulated circulation heating lower block 2, circulation heating middle block 3 and circulation heating upper block 4, and are placed between the cylinder body 6 and the head 7. There is a demister 5. The lower end of the separator 1 is respectively provided with a first temperature measuring port g1, a sampling port g2, and a concentrated material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com