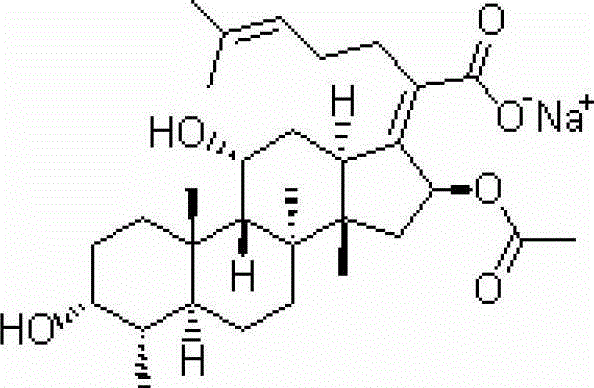

Sodium fusidate lipidosome injection

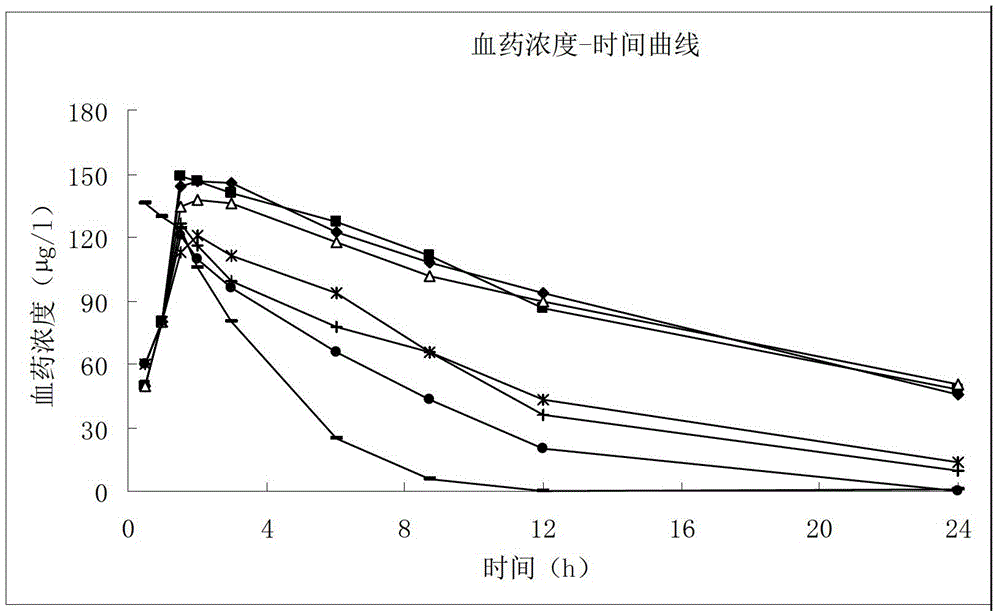

A technology of sodium fusidate and injection, applied in the field of pharmaceutical preparations, can solve the problems of easy aggregation, fusion, and leakage of encapsulated drugs of liposomes, and achieve the effects of improving bioavailability, delaying release, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 sodium fusidate liposome injection

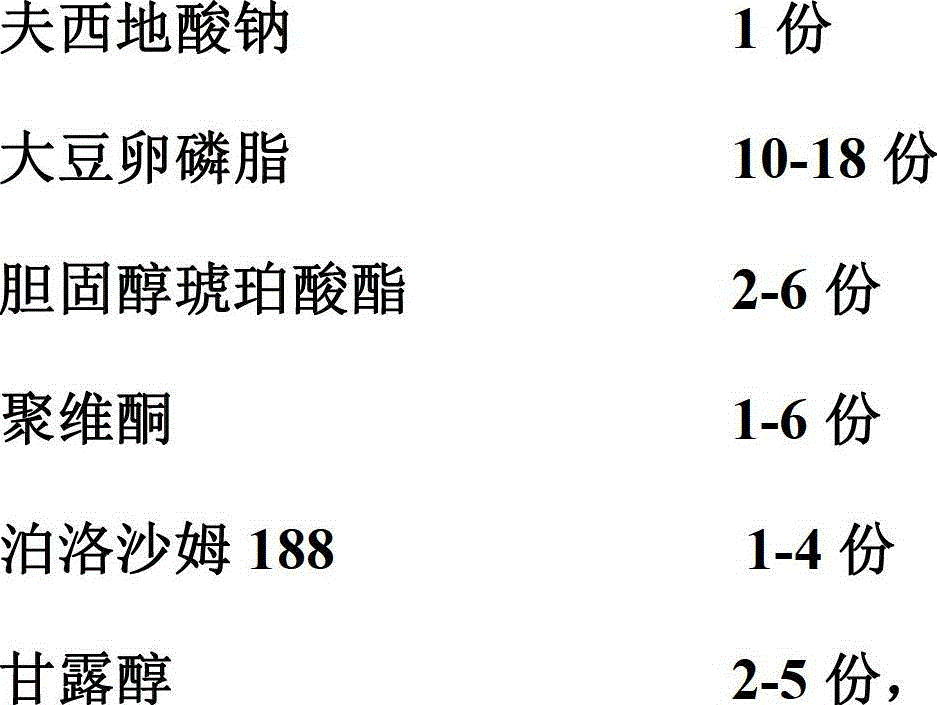

[0060] Prescription: (100 bottles)

[0061]

[0062] making process:

[0063] (1) Dissolve 12.5g of sodium fusidate in 5000ml of phosphate buffer solution with a pH of 7.8, add 50g of povidone, and stir evenly to obtain an aqueous phase;

[0064] (2) Dissolve 200g of soybean lecithin, 50g of cholesterol succinate and 25g of poloxamer 188 in 500ml of a mixed organic solvent of tert-butanol and isopropanol with a volume ratio of 3:1, stir to dissolve; The solution is placed in an eggplant-shaped bottle, and the organic solvent is removed under reduced pressure in a 45°C water bath to form a uniform transparent film on the wall of the bottle;

[0065] (3) Under the protection of nitrogen, add the water phase of step 1 into the bottle; stir to elute the phospholipid film and fully swell and hydrate it, then do gradient homogenization at 300bar to 600bar for 5 times, filter with a 0.22μm microporous ...

Embodiment 2

[0067] The preparation of embodiment 2 sodium fusidate liposome injection

[0068] Prescription: (100 bottles)

[0069]

[0070] making process:

[0071](1) Dissolve 25g of sodium fusidate in 5000ml of phosphate buffer solution with a pH of 7.8, add 75g of povidone, and stir evenly to obtain an aqueous phase;

[0072] (2) Dissolve 350g of soybean lecithin, 87.5g of cholesterol succinate and 50g of poloxamer 188 in 800ml of a mixed organic solvent of tert-butanol and isopropanol with a volume ratio of 3:1, stir to dissolve; The above solution is placed in an eggplant-shaped bottle, and the organic solvent is removed under reduced pressure in a water bath at 45°C to form a uniform transparent film on the wall of the bottle;

[0073] (3) Under the protection of nitrogen, add the water phase of step 1 into the bottle; stir to elute the phospholipid film and fully swell and hydrate it, then perform gradient homogenization at 300bar to 600bar for 4 times, filter with a 0.22μm...

Embodiment 3

[0075] The preparation of embodiment 3 sodium fusidate liposome injection

[0076] Prescription: (100 bottles)

[0077]

[0078] making process:

[0079] (1) Dissolve 50g of sodium fusidate in 10,000ml of phosphate buffer solution with a pH of 7.8, add 100g of povidone, and stir evenly to obtain an aqueous phase;

[0080] (2) Dissolve 600g of soybean lecithin, 150g of cholesterol succinate and 100g of poloxamer 188 in 1200ml of a mixed organic solvent of tert-butanol and isopropanol with a volume ratio of 3:1, stir to dissolve; The solution is placed in an eggplant-shaped bottle, and the organic solvent is removed under reduced pressure in a 45°C water bath to form a uniform transparent film on the wall of the bottle;

[0081] (3) Under the protection of nitrogen, add the water phase of step 1 into the bottle; stir to elute the phospholipid film and fully swell and hydrate it, then do gradient homogenization at 300bar to 600bar for 6 times, filter with a 0.22μm micropor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com