Algal biological feed and preparation method thereof

A seaweed and feed technology, which is applied in animal feed, animal feed, application, etc., can solve the problems of inconspicuous breeding effect, long cycle, high production cost, etc., and achieve the improvement of alanine aminotransferase activity, fast absorption of animals, and immunity enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

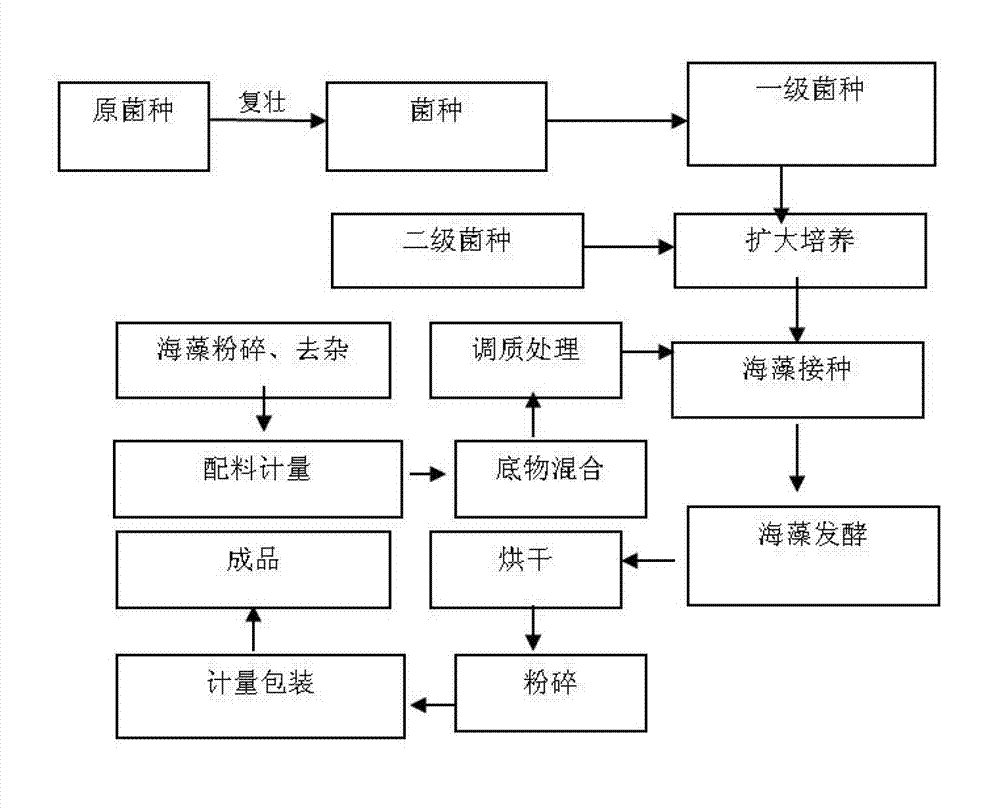

[0031] As shown in Figure 1, the present invention provides a kind of preparation method of seaweed fermentation biological feed, comprises the following steps: Step 1, use 15~25 parts of actinomycetes by weight, 15~25 parts of saccharomycetes, 30~45 parts of subtilis Two or more of Bacillus, 20-35 parts of Lactobacillus casei and 20-35 parts of lactic acid bacteria are used to prepare a composite bacterial agent; step 2, using the composite bacterial agent prepared in the first step to ferment seaweed.

[0032] In the preparation method of the seaweed fermented biological feed, the preparation process of the composite bacterial agent includes the following steps: (1) Weigh the selected bacterial strains according to the weight ratio of the first step, and separately weigh each bacterial strain Cultivate; (2) According to the ratio of the above step (1), mix the respective bacterial liquids obtained from the separate culture.

[0033] In the preparation method of the seaweed f...

Embodiment 1

[0048] step one

[0049] Production of production strains: transfer the screened actinomycetes, Bacillus subtilis, Lactobacillus casei, and lactic acid bacteria into eggplant bottles filled with nutrient agar medium, and transfer the yeast into yeast extract malt juice agar for cultivation In the base eggplant bottle, cultivate it at 35°C for 45 hours, take it out when the surface of the eggplant bottle is covered with bacterial lawn, and turn white with a yellowish color, and then put it in a refrigerator at 2-6°C for storage;

[0050] Nutrient agar medium: beef extract 3g, peptone 10g, NaCl 5g, agar 15-20g, water 1000ml, pH 7.0-7.2. Sterilize at 121°C for 20min.

[0051] Starch medium: peptone 10g, NaC 15g, beef extract 5g, soluble starch 2g, distilled water, agar 15-20g, sterilized at 121°C for 20min.

[0052] Liquid culture of beneficial strains:

[0053] (1) Weigh each strain according to the following percentages by weight: 15g of actinomycetes, 15g of yeast, 30g of B...

Embodiment 2

[0080] step one

[0081] Production of production strains: transfer the screened actinomycetes, Bacillus subtilis, Lactobacillus casei, and lactic acid bacteria into eggplant bottles filled with nutrient agar medium, and cultivate them at 35°C for 45 hours. It can be taken out when the lawn is covered with white and yellowish, and then stored in a refrigerator at 2-6°C;

[0082] Nutrient agar medium: beef extract 3g, peptone 10g, NaCl 5g, agar 15-20g, water 1000ml, pH 7.0-7.2. Sterilize at 121°C for 20min.

[0083] Starch medium: peptone 10g, NaC 15g, beef extract 5g, soluble starch 2g, distilled water, agar 15-20g, sterilized at 121°C for 20min.

[0084] Liquid Culture of Beneficial Bacteria

[0085] (1) Weigh each strain according to the following weight percentages: 15g of actinomycetes, 45g of Bacillus subtilis, 20g of Lactobacillus casei, and 20g of lactic acid bacteria.

[0086] (2) Liquid culture of actinomycetes

[0087] Same as Example 1

[0088] (3) Liquid cult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com