Peptide product for promoting calcium absorption and manufacture method thereof

A calcium absorption and peptide technology, applied in the field of peptide products, can solve the problems of complicated steps, insufficient hydrolysis reaction, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Promoting the manufacture of calcium absorption soybean peptide

[0020]Using defatted soybean meal as raw material, inoculate Aspergillus sojae (Aspergillus sojae), wherein, the inoculum amount of Aspergillus is 0.013% of the total weight of soybean raw material, and the concentration is 0.25% by weight of CH 3 COONa / 0.25%HNaSO 3 , pH = 5.8 buffer solution to adjust the water content to 55%, and cultured for 2 days at 25-30° C. and a relative humidity of 95% or more.

[0021] Then carry out the hydrolysis reaction, mix soybean koji with water, wherein the ratio of soybean koji to water is 1:2, the hydrolysis time is 6 hours, and the hydrolysis temperature is 45°C, then increase the temperature to 90-95°C and keep it for 10 minutes. Inhibits enzyme activity.

[0022] Next, carry out the clarification treatment of the hydrolyzate, first use the press machine, put the soybean hydrolyzate in the filter bag, spread it on the press tank, and separate the solid a...

Embodiment 2

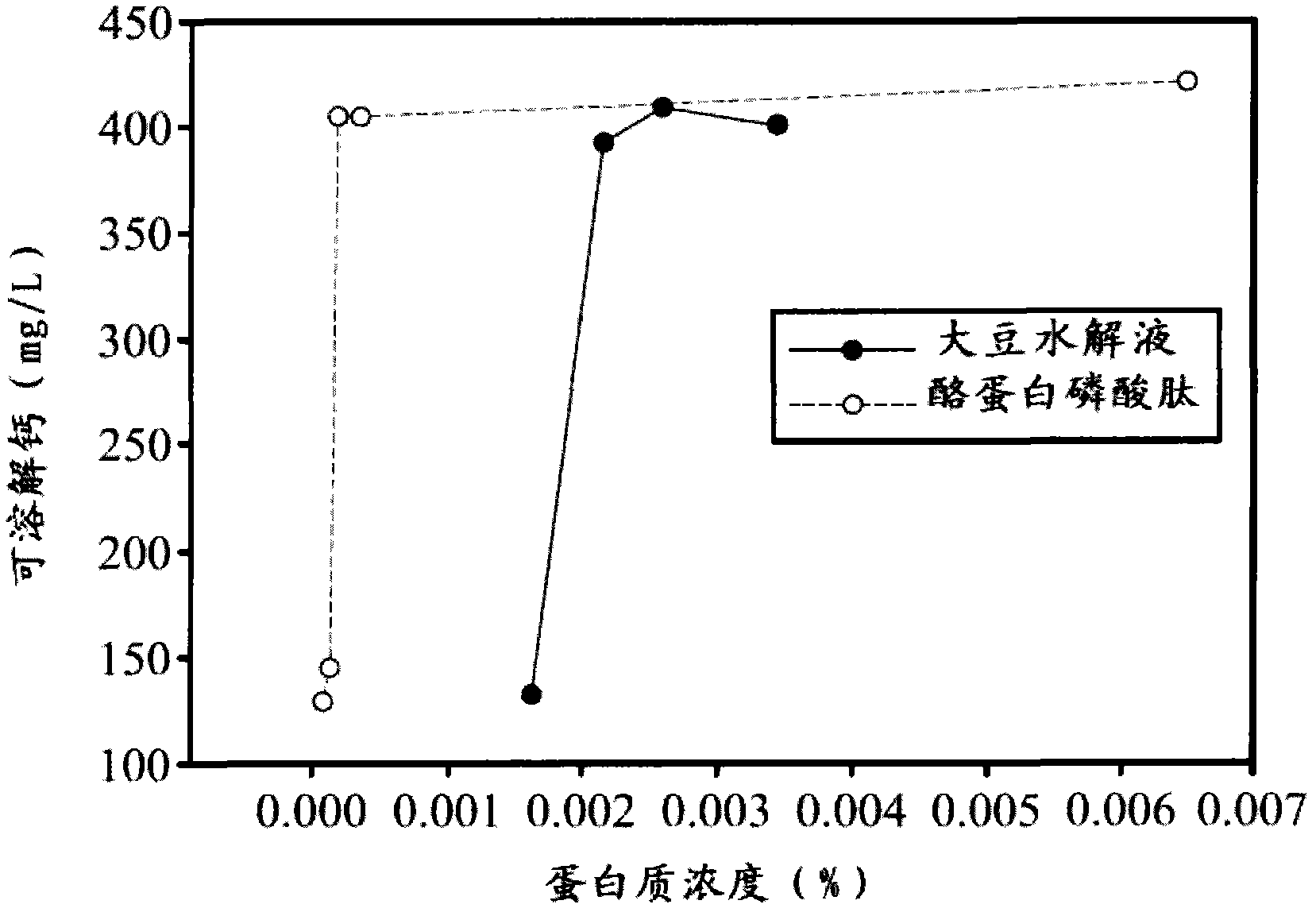

[0023] Embodiment 2. Soybean hydrolyzate inhibits the effect of calcium carbonate precipitation

[0024] According to Jin et al. (J.Agnc.Food Chem.2000) calcium carbonate crystallization experiment slightly modified, 1mL sample was mixed with 1mL 40mM calcium chloride and 1.2mL distilled water, then added 0.8mL 40mM sodium bicarbonate to react 1 hour and titrate with 0.1N NaOH to maintain pH = 8.5. The mixed solution that finishes reaction is centrifuged (centrifugal force is 2000g), gets supernatant and uses calcium measuring reagent group (Taiwan Merck company product) to measure calcium concentration, and this is soluble calcium content.

[0025] In the experiment of inhibiting calcium carbonate crystallization, the soybean protein hydrolyzate obtained by embodiment 1 has an inhibitory effect on calcium carbonate crystallization, and the evaluation of this effect is under alkaline conditions (pH=8.5), completely inhibiting the minimum sample concentration of calcium carbona...

Embodiment 3

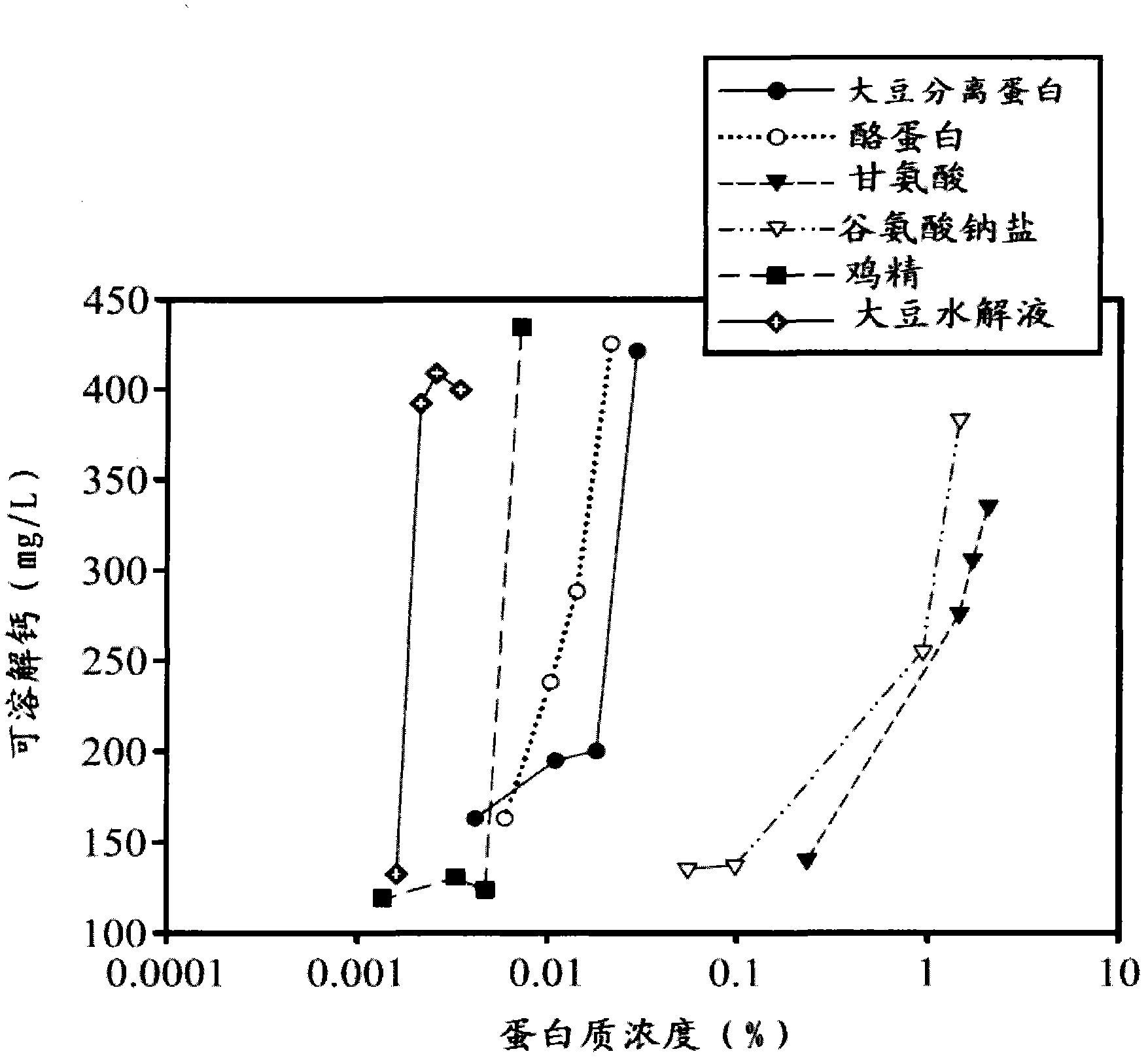

[0026] Example 3. Effect of Soybean Hydrolyzate Inhibition

[0027] In this example, different protein sources were selected for comparison, 1 mL of sample was mixed with 1 mL of 40 mM calcium chloride and 1.2 mL of distilled water, and then 0.8 mL of 40 mM sodium bicarbonate was added to react for 1 hour, and 0.1 N hydrogen Titrate with sodium oxide to maintain pH = 8.5. The mixed solution that finishes reaction is centrifuged (centrifugal force is 2000g), gets supernatant and uses calcium measuring reagent group (Taiwan Merck company product) to measure calcium concentration, and under alkaline condition (pH=8.5), suppress carbonic acid completely The lowest sample concentration of calcium crystallization was used as an evaluation criterion for soluble calcium content.

[0028] figure 2 Inhibitory effect of calcium carbonate crystallization for different protein source substances. Among them, free amino acids such as sodium glutamate (monosodium glutamate, MSG) and glyci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com