Plastic screw plug for attaching a rail to a sleeper

A technology of screw pins and sleepers, applied in the field of plastic screw pins, can solve the problems of weakening and destruction of plastic pins, and achieve the effect of optimizing the thread geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

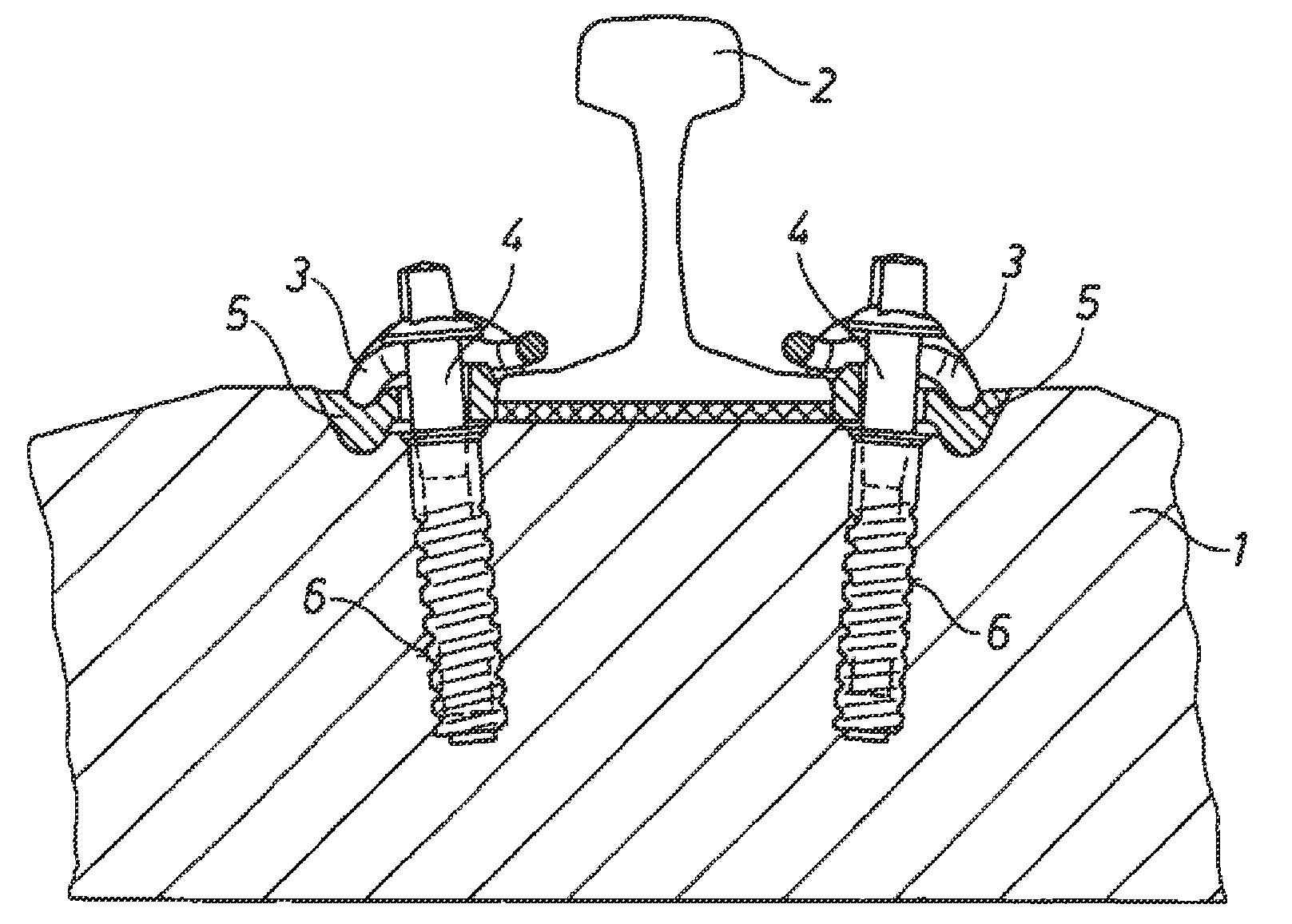

[0030]1 and 2 show a common rail fastening system, in which the basic rail (Backenschiene) 2 laid on the concrete sleeper 1 is fixed by means of tensioning clamps 3 and sleeper bolts 4, which are connected in the middle of the angle guide plate Next, the central loop of the tensioning clamp 3 is screwed into the plastic screw pin 6 of the concrete sleeper 1 .

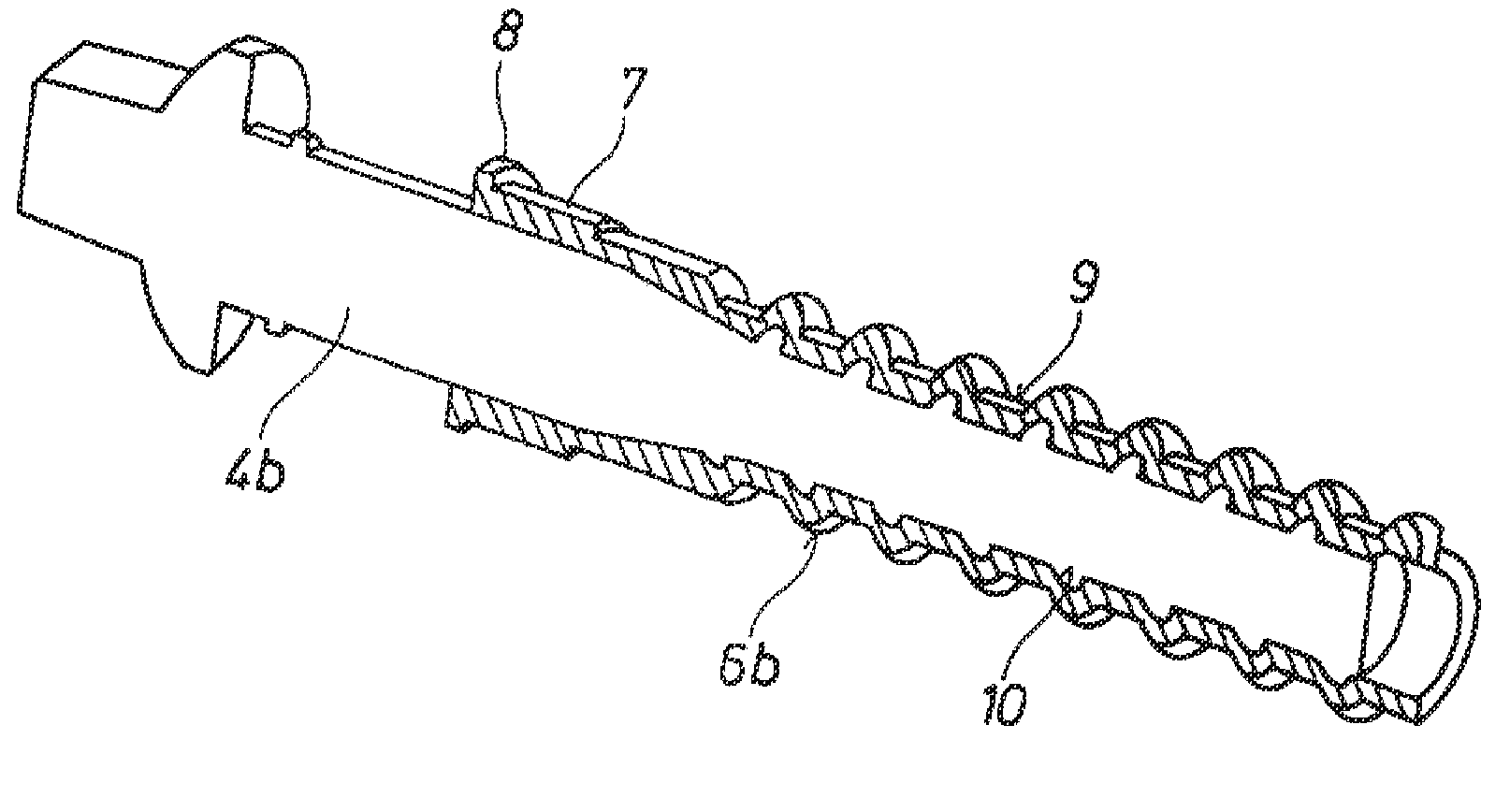

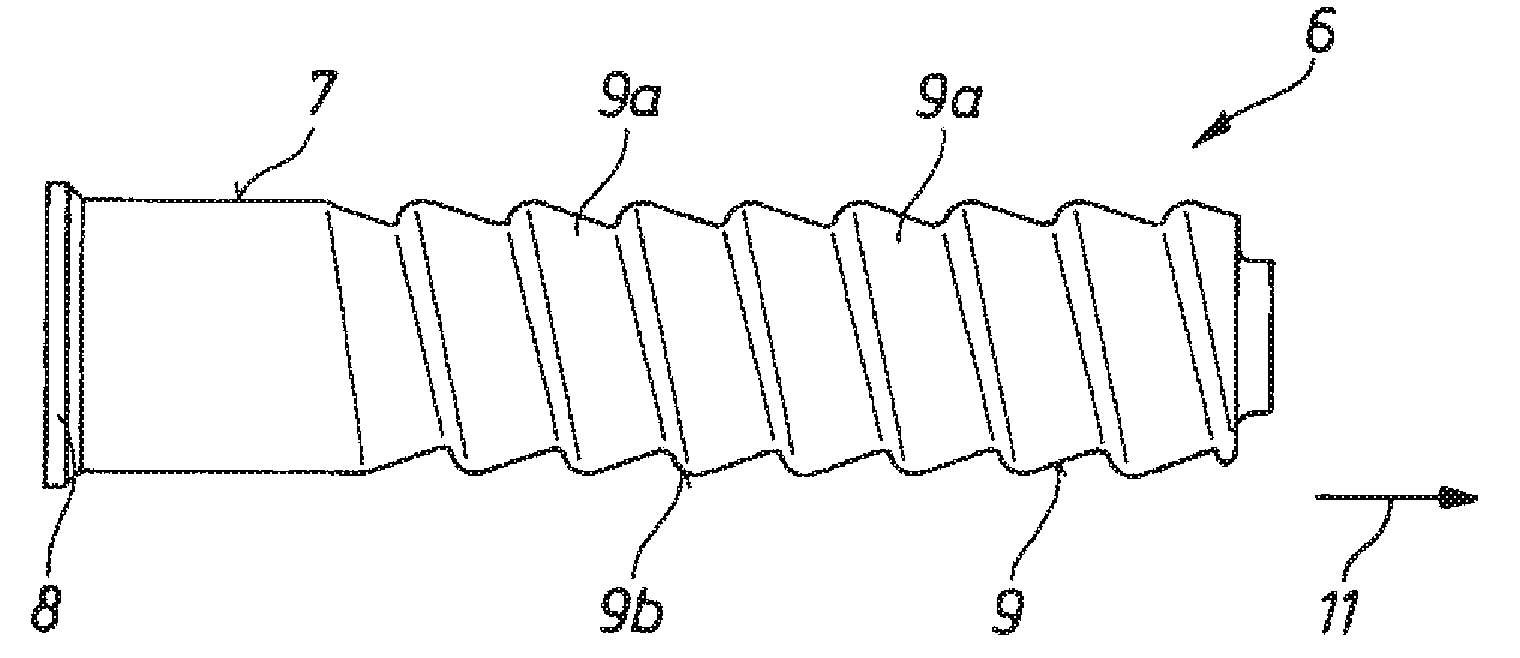

[0031] Here, a sharp-angled thread-crossie bolt 4a (see FIG. 3 ) or a round thread-crossie bolt 4b (see FIG. 4 ) is used, which is associated with a correspondingly matched sharp-angled thread-plastic screw pin 6a or round thread-plastic screw pin 6b. The plastic screw pin 6 or 6a, 6b has an approximately cylindrical pin body, which on the head side has a shank region 7 optionally with a pin crown 8 (see FIG. 4 ) and on the one hand has serrations in its continuation. An external thread 9 and on the other hand an internal thread 10 .

[0032] In the two embodiments of the plastic screw pin 6 shown in FIGS. 5 to 7 or 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com