Coil panel and assembling method of coil panel and coil panel support and electromagnetic range

An assembly method and a coil disk technology, which are applied in the field of electromagnetic cookers, can solve the problems of harmful smell of glue, affecting the heat dissipation of coil windings, increasing the length and area of coil windings, etc., and achieve the effects of avoiding electrical interference, increasing thermal efficiency, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

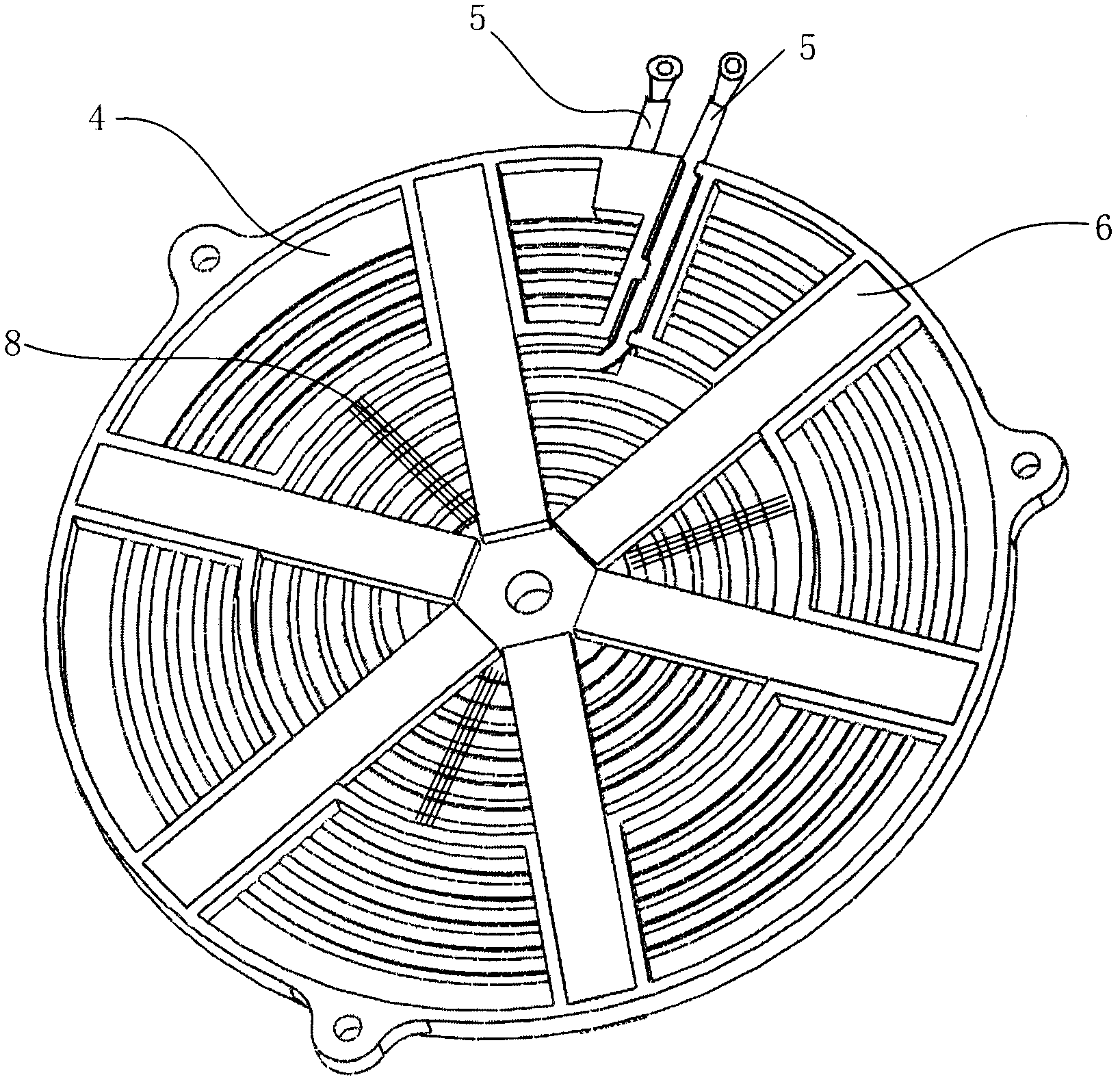

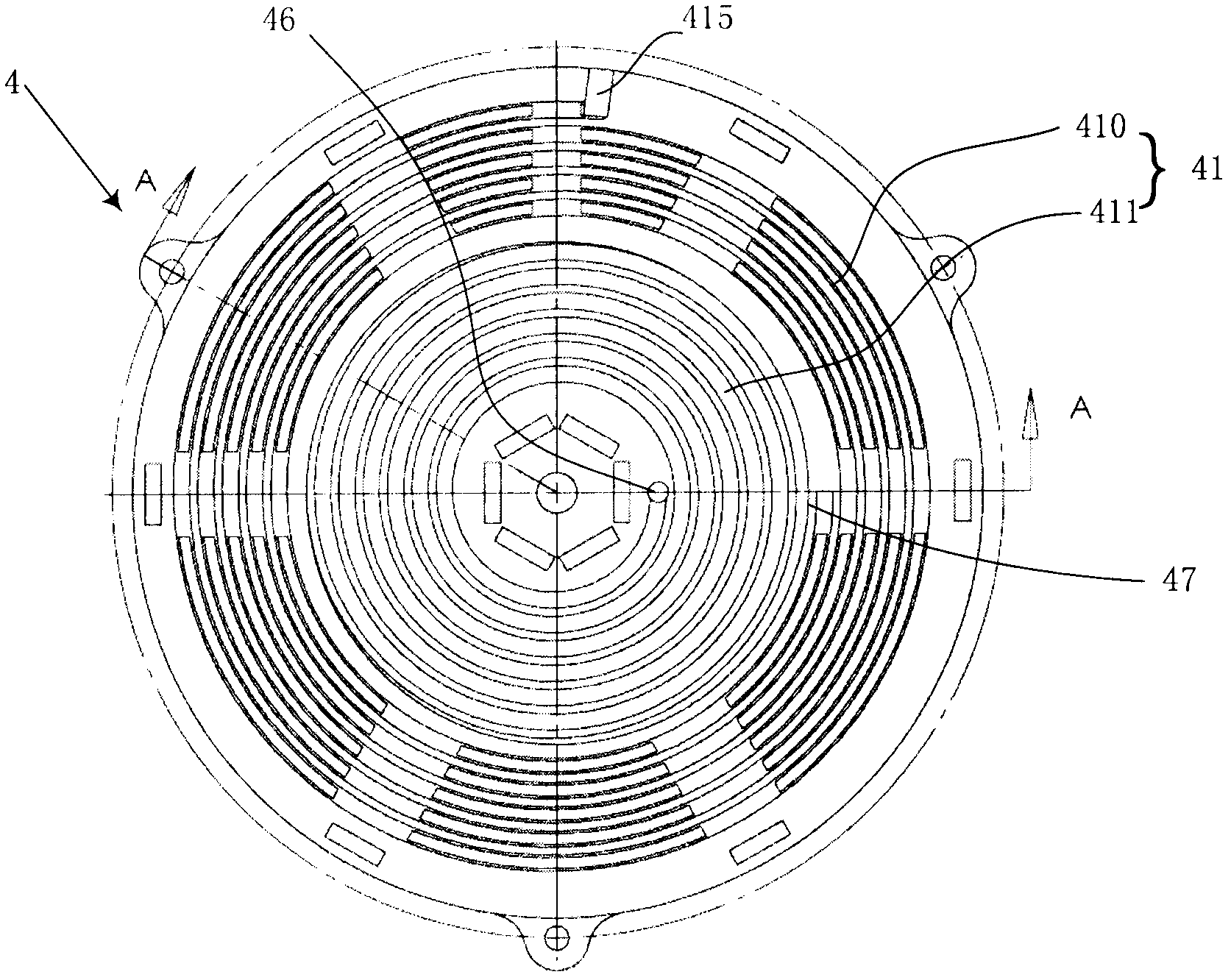

[0058] The double-layer electromagnetic cooker coil disk provided by the first embodiment of the present invention, such as Figure 1 to Figure 2As shown, it is generally composed of a coil disk support 4, a coil 5, a magnetic strip 6, and the like. The coil disc support has a first surface ( figure 1 The upper surface in the application, also referred to as the upper surface) and the second surface ( figure 2 The surface where the magnetic strip 6 is located is also referred to as the lower surface in this application), and the coil 5 is coiled on the first surface and the second surface of the coil disk support 4 . Because the coil 5 is wound on the two surfaces of the coil disc support 4, compared with the existing single-layer coil structure, the length of the coil 5 in the same area is doubled, and accordingly, the thermal efficiency of the coil disc and the electromagnetic range using the coil disc will increase substantially. In addition, since the coils 5 on the up...

no. 2 example

[0069] The coil disk provided by the second embodiment of the present invention, such as Figure 7 to Figure 12 shown. The structure of the coil plate of the second embodiment is substantially the same as that of the first embodiment, the main difference is that the second embodiment uses alternating slots 70 or 75 to replace the coil via holes 46 in the first embodiment, as the channel between the first surface and the second surface . For the convenience of description, the names and reference numerals of the first embodiment will be used here for the same or substantially the same structures, and will not be described in detail in the specification.

[0070] Alternating slots 70 or 75 penetrate the first surface and the second surface of the coil disk support 4 to communicate with the coil slots (including the outer coil slot 410, the inner coil slot 411 and the second coil slot 42) located on the first and second surfaces, It facilitates the winding of subsequent coils. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com