Remote real-time control method for site mixed and loaded explosive truck and device thereof

A technology of on-site mixed explosives, remote management device, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc. Good effect, improved flexibility and security, high security and real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

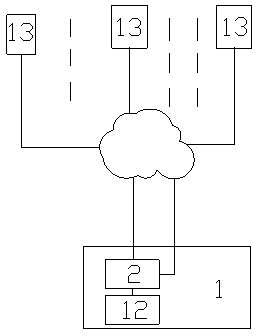

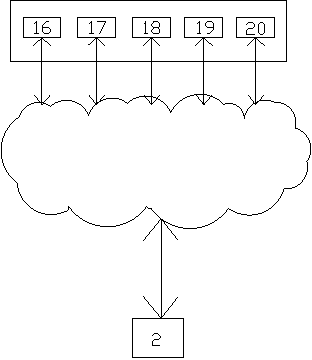

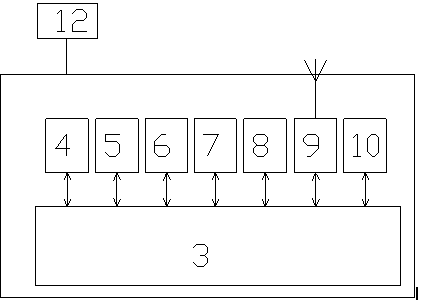

[0037] Embodiment of the present invention: the remote real-time management and control method of the on-site mixed explosives vehicle, the on-site mixed explosives vehicle is installed with a vehicle-mounted intelligent control console with standard working parameters in advance, and the on-site mixed explosives vehicle is collected by the vehicle-mounted intelligent control console. Working parameters, and compare the collected real-time working parameters with the standard working parameters. When the real-time working parameters meet the requirements of the standard working parameters, the vehicle-mounted intelligent control console will automatically start to control the production start of the on-site mixed explosives vehicle production. Force device, when the real-time working parameters do not meet the requirements of the standard working parameters, the vehicle-mounted intelligent control console will automatically interlock the production force device, so that the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com