Production management device for sewing machine

A production management and sewing machine technology, applied in program-controlled sewing machines, sewing equipment, textiles and papermaking, etc., can solve the problems of difficult production completion date production, no record of production process, inability to understand the number of sewing pieces and production process, etc., to achieve effective The effect of production management and efficient production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The production management device of the present invention is incorporated into a part of the function of the sewing device (sewing machine), and can grasp the production process during sewing with a simple structure. Hereinafter, the present invention will be described in detail with reference to the accompanying drawings according to the embodiments of the present invention.

[0030] (Example)

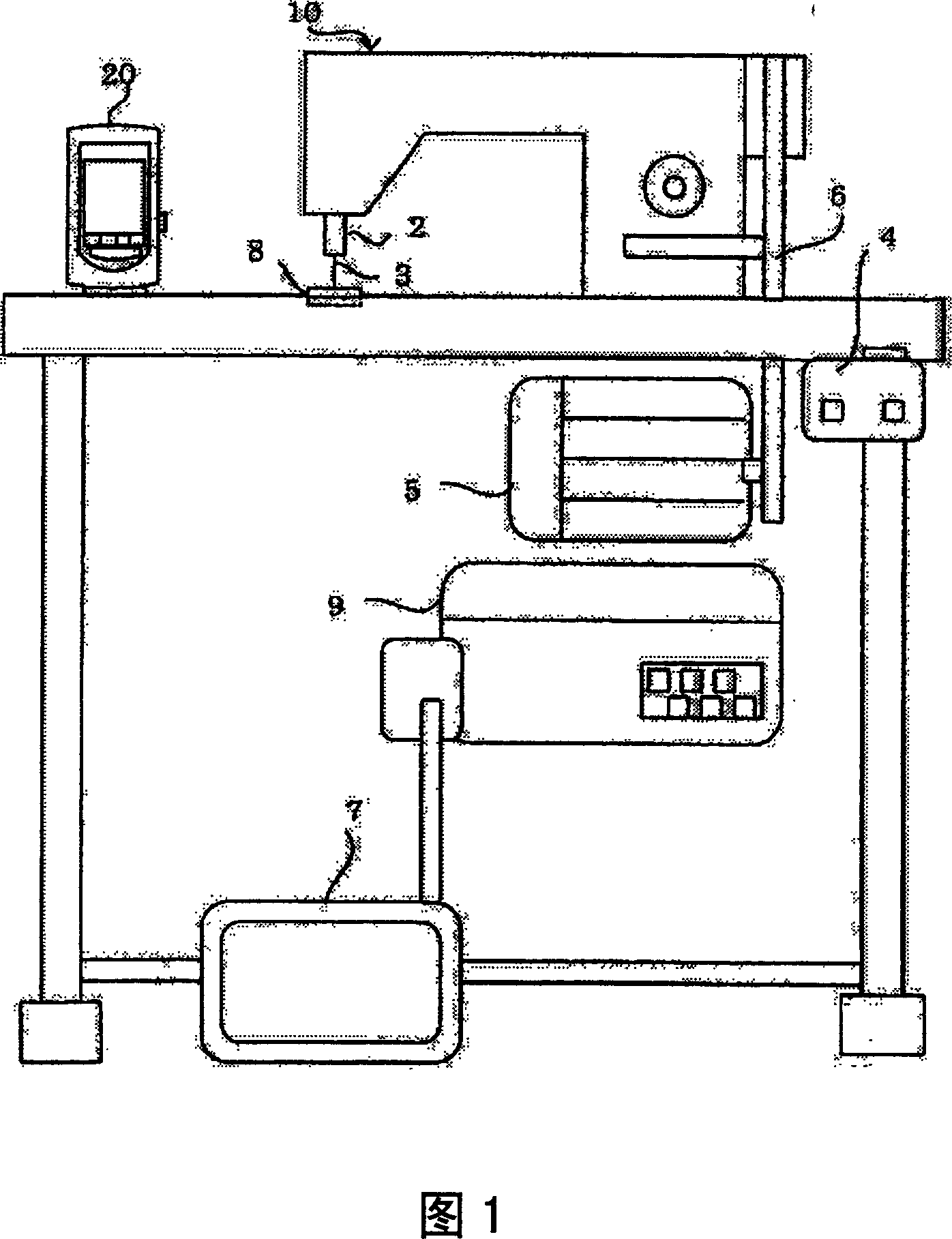

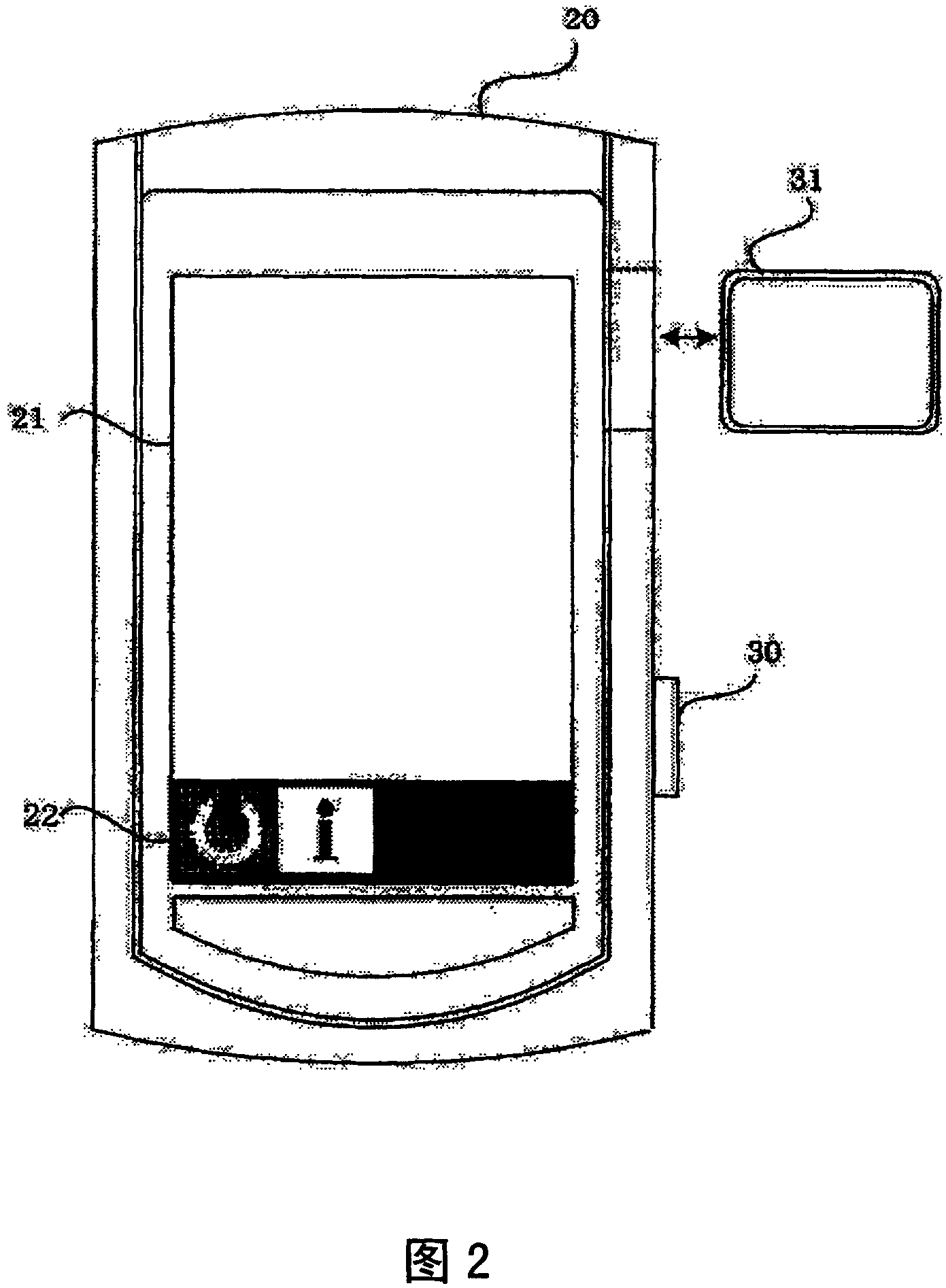

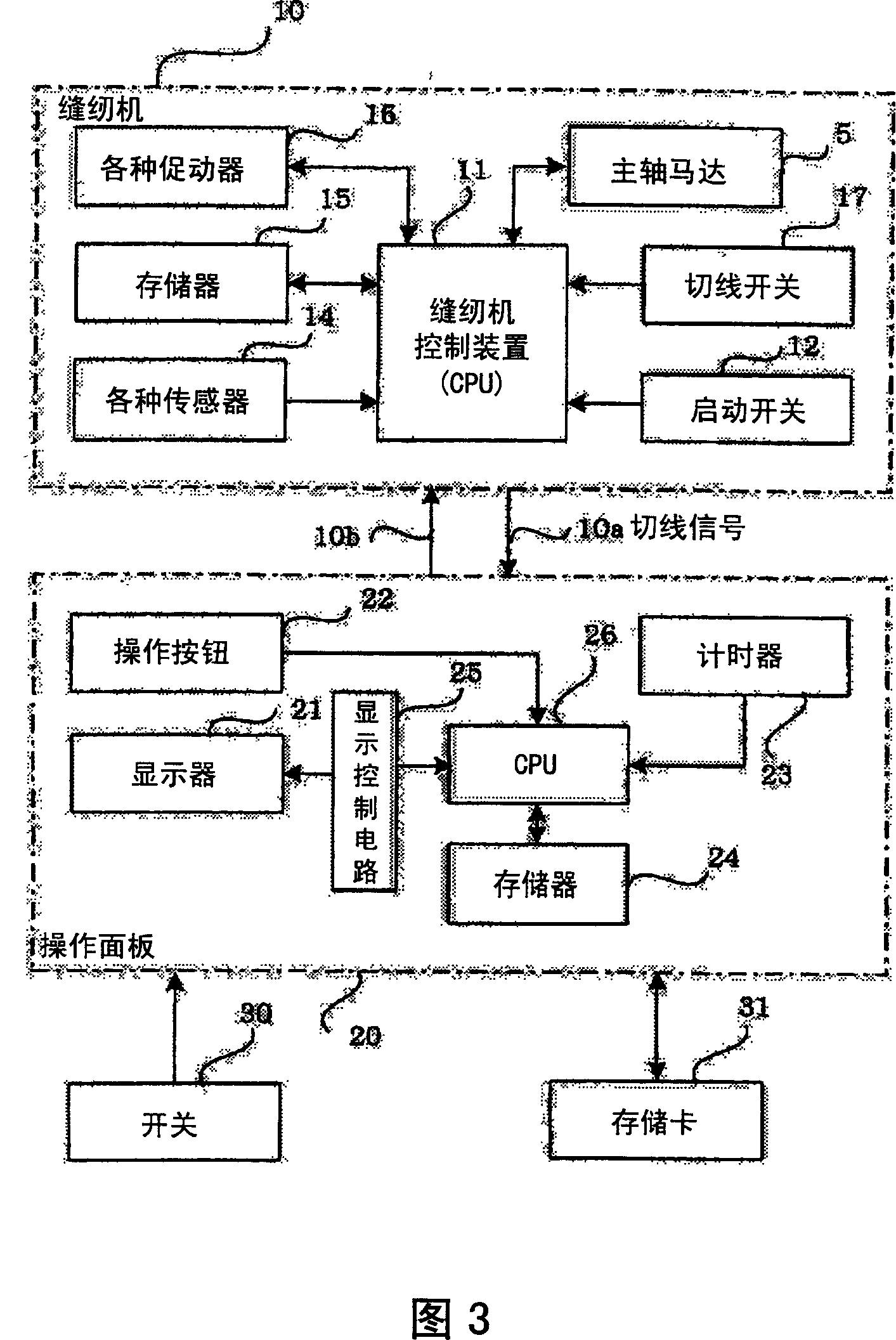

[0031] The production management device of the present invention, such as figure 1 As shown, it is assembled in a sewing system composed of a sewing machine 10 and an operation panel 20 connected thereto.

[0032] In the sewing machine 10, the needle 3 is supported by the needle bar 2 thereof, and the main shaft motor 5 supplied with power by turning on the power switch 4 rotates and the rotation is transmitted to the main shaft by the belt 6, thereby moving up and down. According to this needle movement, the cloth is fed by the cloth feeding device 8 at a predetermined cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com