Y-shaped wear-resistant glasses plate and manufacturing method

A spectacle plate and font technology, which is applied to liquid variable volume machinery, components of pumping devices for elastic fluids, variable volume pump components, etc. Low problems, to achieve the effect of improving the overall wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

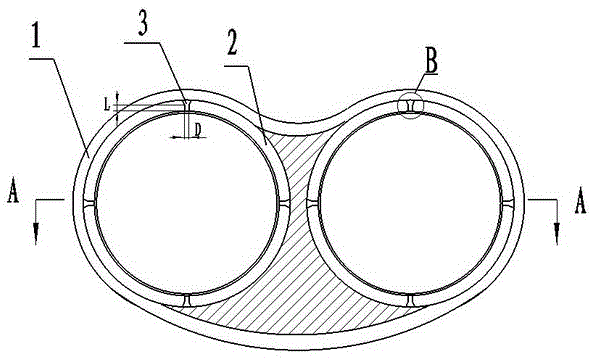

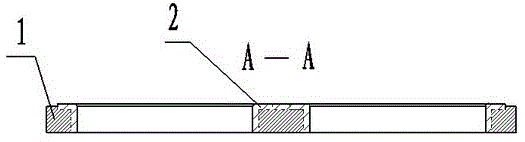

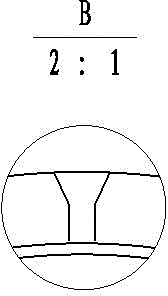

[0017] As shown in the figure, a Y-shaped wear-resistant spectacle plate includes a spectacle plate body 1 and a hard alloy wear-resistant layer on its working surface, and a cemented carbide block 2 is tailor-welded on the hard alloy wear-resistant layer. The matching gap between the hard alloy blocks 2 is a Y-shaped gap 3, and the Y-shaped gap 3 is filled with flux. The quantity of said cemented carbide block 2 is 4 pieces. The thickness of the hard alloy wear-resistant layer is 6mm. The welding method of the cemented carbide block 2 is brazing. The gap D between the Y-shaped slit 3 and the end of the feed hole is 1 mm. The included angle between the edge lines of the Y-shaped slit 3 is 30 degrees. The Y-shaped slit 3 is a parallel straight section with a length L of 2 mm near the feeding hole.

[0018] The gap between the cemented carbide blocks 2 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com