Keel connecting piece for building modular clean operating room

A modular, operating room technology, applied in the direction of architecture, building structure, etc., can solve the problem of difficulty in guaranteeing the overall quality level, and achieve the effect of reducing the impact of product quality and improving technical quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes a corner joint piece 1 , a riveting piece 2 and a hook piece 3 .

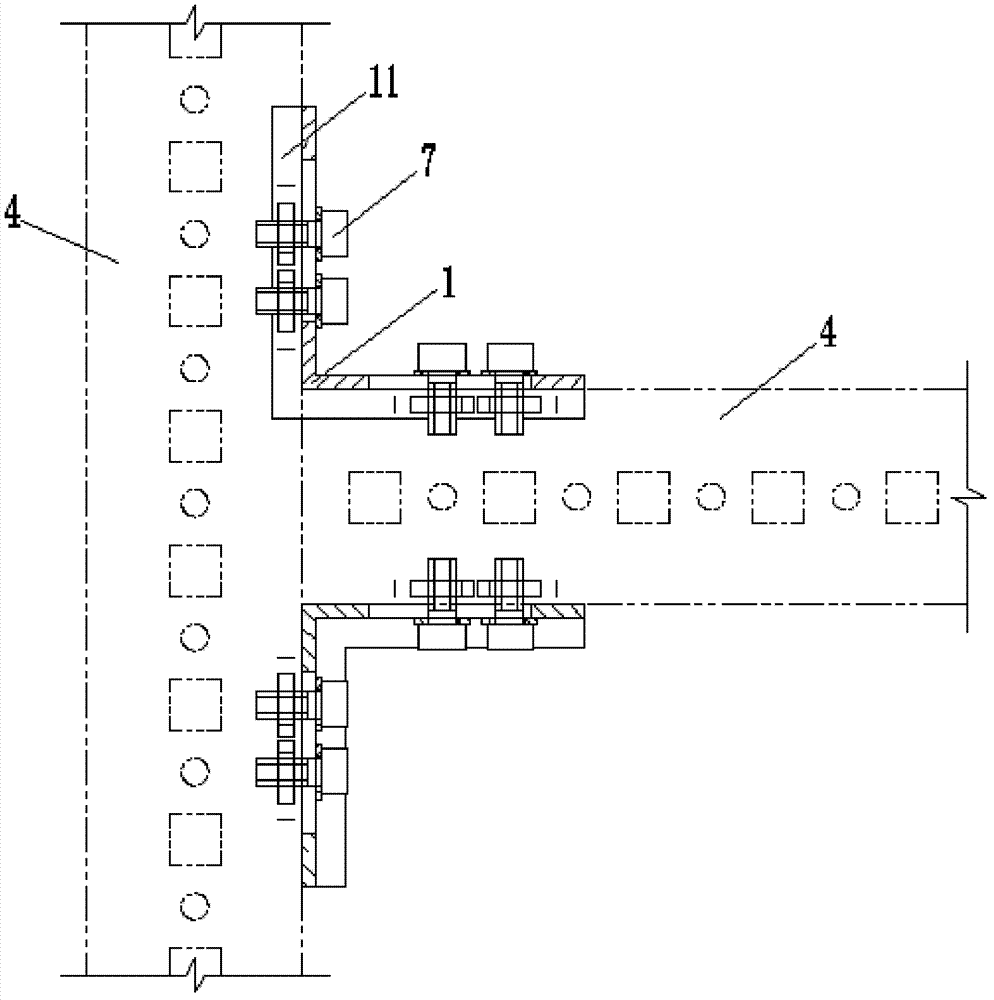

[0030] See figure 1 , when the two keels 4 are fixedly connected, the corner joint 1 is fixedly connected with the two keels 4 through the threaded fastener 7 .

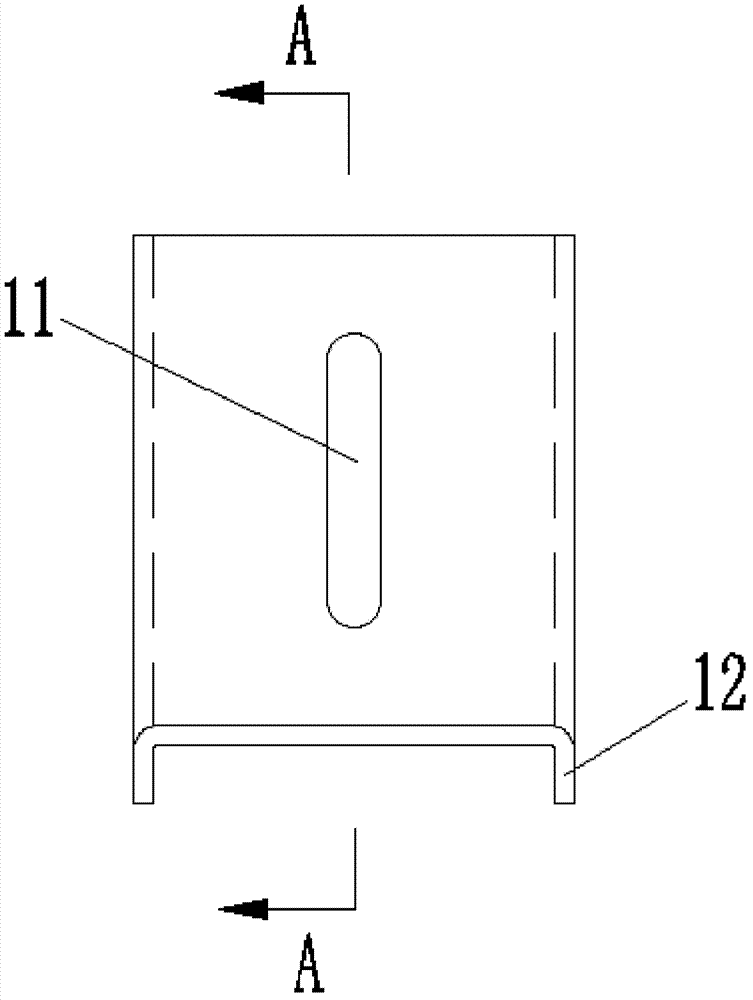

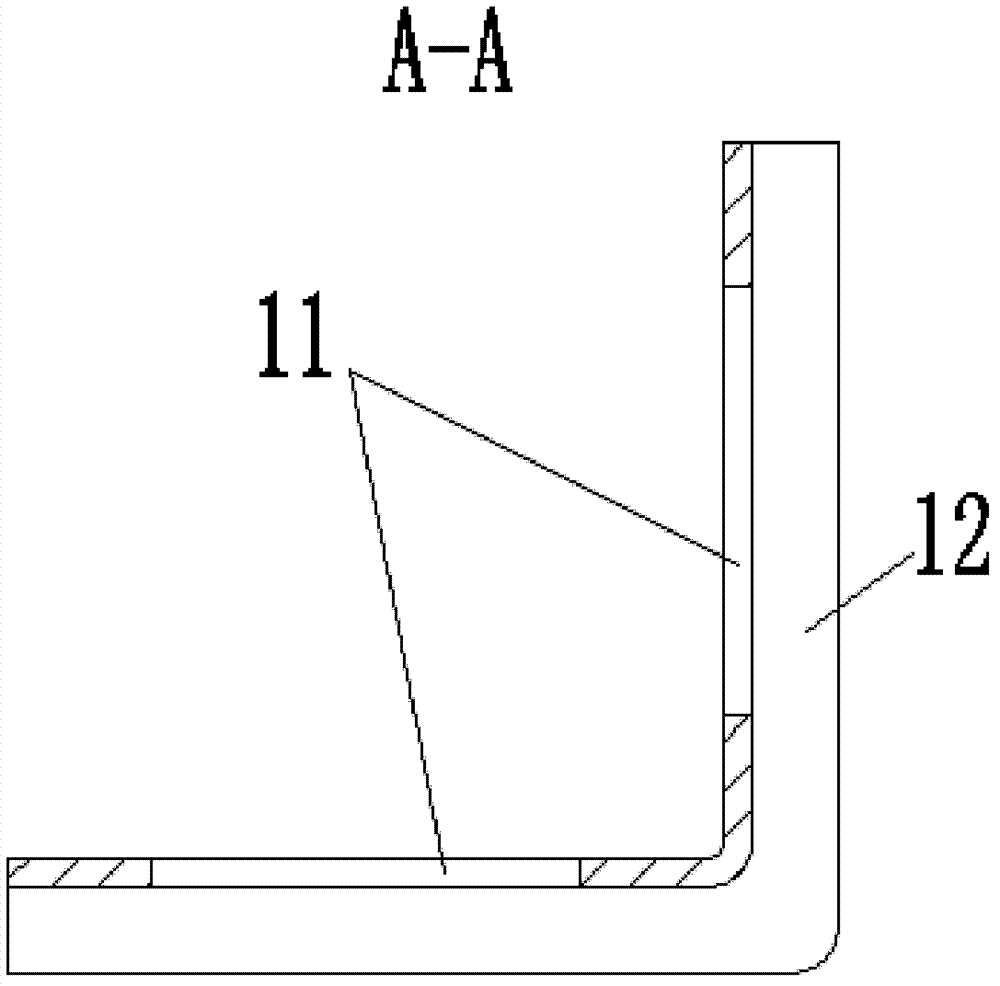

[0031] See figure 2 and image 3 , The longitudinal section of the corner joint 1 is equilateral and right-angled. Both sides of the corner joint 1 are provided with guide flanges 11 . The width and thickness of guide flanging 11 are all matched with keel 4. Both sides of the corner joint 1 are provided with oblong positioning holes 12 .

[0032] See Figure 4 , when the wallboard 5 is fixedly connected to the keel 4, the wallboard 5 is fixedly connected to the riveting part 2 through the rivet 8, and the riveting part 2 is fixedly connected to the keel 4 through the threaded fastener 7.

[0033] See Figure 5 and Figure 6 , the longitudinal section of the riveting piece 2 is in a right-angle Z shape. One ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com