Knife lip wiping apparatus

A knife lip and air knife technology, which is applied in the field of knife lip wiping devices and devices for cleaning foreign matter attached to the knife lip of air knives. It can solve the problems of easy wear of the knife head, inability to adjust the blowing angle, and jamming, etc., and achieve improved cleaning. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

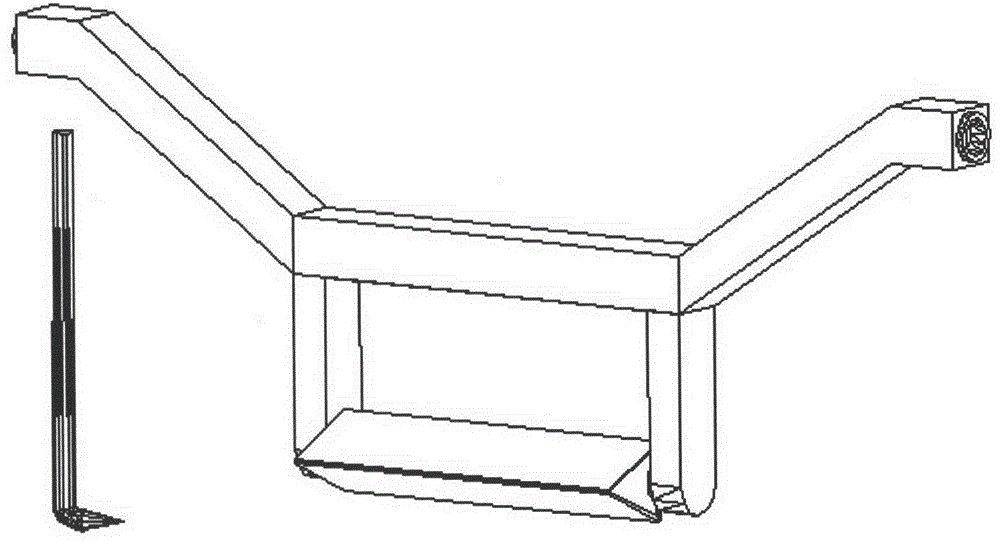

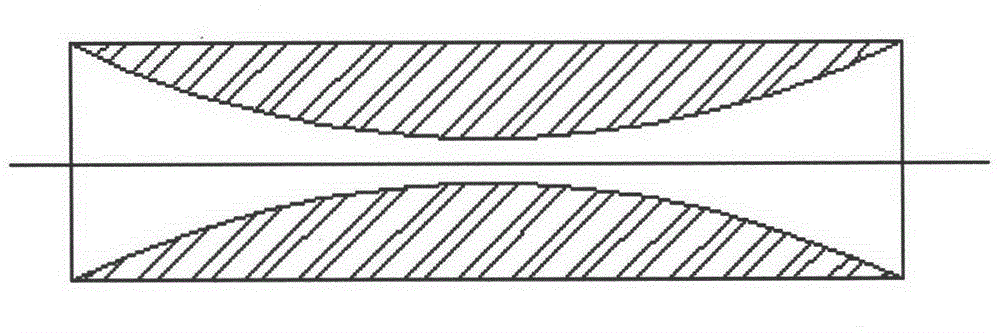

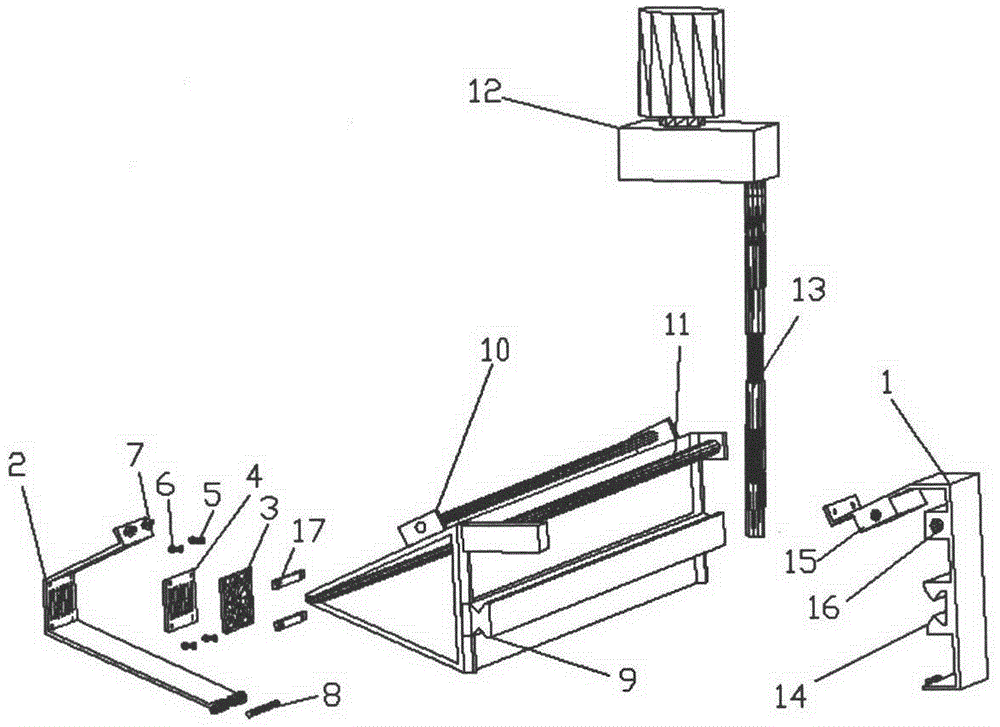

[0021] The basic structure of the air knife lip wiping device of the present embodiment is as follows: image 3 As shown, the air knife device has a blowing lip with a triangular cross-section. The back side of the air knife device away from the lip has a horizontal rail 9 extending along the length direction, and a rotatable horizontal screw 11 driven by a reduction motor 12 on the air knife device through a universal connecting shaft 13 and a helical gear. The air knife device is equipped with a triangular wiping frame composed of a fixed " Figure 4 As shown, four hexagon socket bolts 5 pass through the upper and lower pressure plates 17 respectively to line the rectangular wiping body 3 with the mesh liner 4, pass through the spring 6 respectively, and screw on the front bracket 2, that is, the rectangular wiping body liner is Behind the mesh liner, it is installed on the front bracket by springs. Therefore, after assembly, the wiping body can be pressed against the lip by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com