Lemongrass dehydration method capable of preparing lemongrass essential oil incidentally

A technology of lemongrass essential oil and lemongrass, which is applied in the direction of essential oil/fragrance, preliminary treatment to promote the drying of solid materials, lighting and heating equipment, etc., and can solve the problems of waste discharge and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

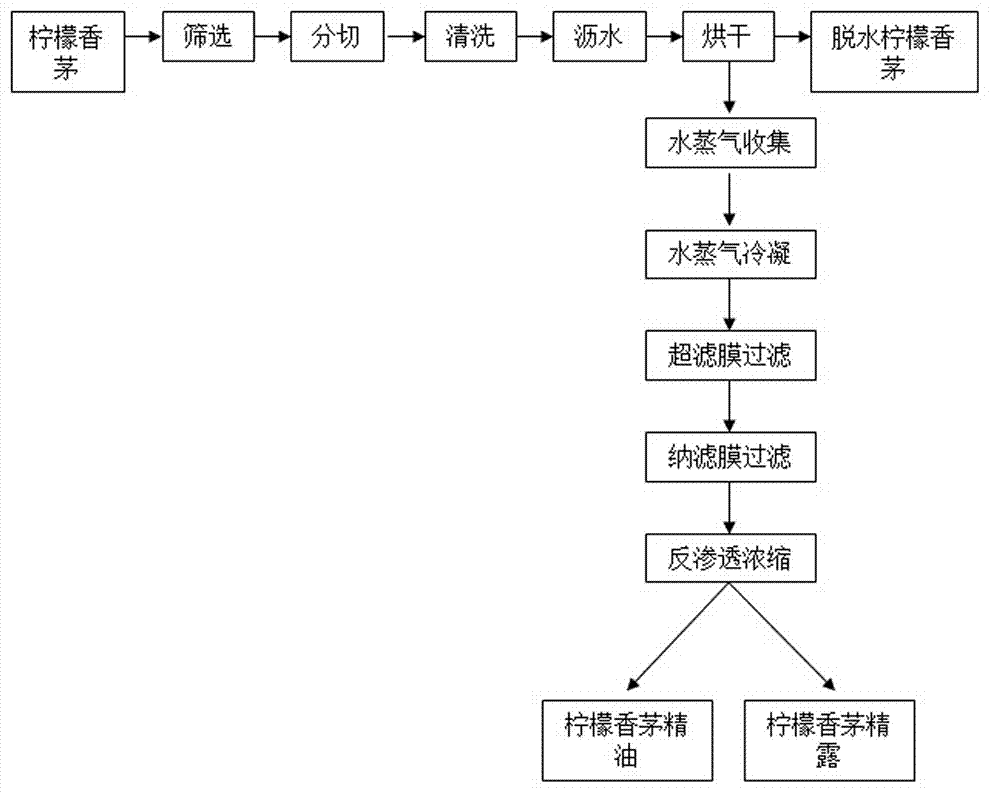

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: take by weighing 100 kilograms of freshly collected lemongrass, use a screening machine to screen and remove impurities such as clods, rotten leaves, and then utilize a fully automatic cutting machine to cut lemongrass into about 3 cm in length, then divide The cut lemongrass is sent to the washing machine for cleaning for 30 minutes, and then dried and drained with a dryer for 30 minutes. After draining, it is sent to a box-type airtight dryer for drying and dehydration. The box-type airtight dryer belongs to intermittent drying equipment. It is mainly composed of a box body, a shelf, a heater, a fan, an exhaust port, and an air distributor. The outer wall of the compartment (drying room) has a thermal insulation layer, and the shelves are used to place the lemongrass after screening, cutting, cleaning and draining. Fans are used to force clean air in and expel humid gases. The drying heat source can be a far-infrared heater arranged in the cabin, or hot...

Embodiment 2

[0019] Example 2: In this example, the cutting step is omitted, and 100 kg of freshly collected lemongrass is screened by a screening machine to remove impurities such as mud and rotten leaves, and then directly sent to a washing machine for cleaning for 30 minutes, and the drying temperature is 65°C , the drying time was 5 hours, and all the other operating methods and steps were the same as in Example 1. The dehydrated lemongrass made in this example was about 35 kilograms, the lemongrass essential oil was about 80ml, and the lemongrass essence was about 50 ml. Kilogram.

Embodiment 3

[0020] Embodiment 3: In this embodiment, steps such as screening, cutting, cleaning, and draining are omitted, and 100 kilograms of freshly collected lemongrass are directly sent into a box-type airtight dryer for drying and dehydration. The drying temperature is 75 ° C. The drying time was 5 hours, and all the other operating methods and steps were the same as in Example 1. The dehydrated lemongrass obtained in this example was about 25 kg, the lemongrass essential oil was about 30ml, and the lemongrass essence was about 45 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com