A polyvinyl alcohol-based composite coating film fresh-keeping packaging material nano-tio2 functional modification method

A polyvinyl alcohol-based, coating film preservation technology, applied in the direction of coating, etc., can solve the problems of poor water resistance and moisture resistance, low antibacterial preservation function, etc., to improve water resistance and film-forming barrier performance, improve antibacterial preservation function, The effect of reducing moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

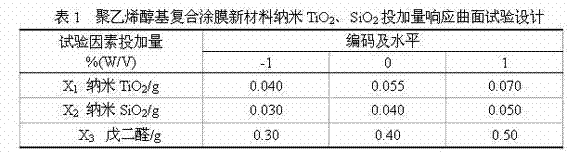

[0023] Nano TiO 2 , SiO 2 Add it into an aqueous solution of polyvinyl alcohol with a concentration of 50 g / L and stir it, place it in an ultrasonic water bath, and ultrasonicate it for 20 minutes under the condition of a power density of 65W / L. Nano-TiO 2 and SiO 2 After being uniformly dispersed in the polyvinyl alcohol solution, the mixed solution was heated in a reactor until the temperature reached 90°C and stirred for 5.5 hours at a constant temperature, then stearic acid-alcohol (ethanol content of 90-99% ethanol) was added at the same temperature (90°C) ) mixed solution, the mass volume ratio of stearic acid to alcohol is 1:20, the amount of stearic acid solution added is 4.5g / L according to the mass volume ratio of polyvinyl alcohol aqueous solution, glutaraldehyde is added at the same time, and the Combined reaction for 50 minutes, then stirred and cooled to room temperature to prepare a new nano-modified composite coating film material.

[0024] Nano-TiO 2 , SiO...

Embodiment 2

[0029] 0. 4 g / L nano-TiO 2 , 0. 3 g / L nano-SiO 2 Added to a concentration of 30g / L H2O After being stirred in an aqueous solution of polyvinyl alcohol, place it in an ultrasonic water bath, and ultrasonicate for 15 minutes under the condition of a power density of 58W / L. Nano-TiO 2 and SiO 2 After being evenly dispersed in the polyvinyl alcohol solution, the mixed solution was placed in a reactor and heated until the temperature reached 85°C and stirred at a constant temperature for 5 hours, then added stearic acid-alcohol (95% ethanol content) at the same temperature (85°C) for mixing Solution, the mass volume ratio of its stearic acid and alcohol is 1:15, and the stearic acid liquid addition amount is 4g / L according to the mass volume ratio with polyvinyl alcohol aqueous solution, adds the glutaraldehyde of 4g / l simultaneously, under constant temperature The cross-linking reaction was 40 min, then stirred and cooled to room temperature to prepare a new nano-modified compo...

Embodiment 3

[0031] 0. 4 g / L nano-TiO 2 , 0. 3 g / L SiO 2 Added to a concentration of 80g / L H2O After being stirred in an aqueous solution of polyvinyl alcohol, place it in an ultrasonic water bath, and ultrasonicate for 25 minutes under the condition of a power density of 70W / L. Nano-TiO 2 and SiO 2 After being evenly dispersed in the polyvinyl alcohol solution, the mixed solution is heated in a reactor until the temperature reaches 95°C and stirred for 6 hours, and then stearic acid-alcohol (90-99% ethanol content) is added at the same temperature (95°C) ) mixed solution, the mass volume ratio of stearic acid to alcohol is 1:25, and the amount of stearic acid liquid added is 5g / L according to the mass volume ratio of polyvinyl alcohol aqueous solution. At the same time, 4g / l glutaraldehyde was added, and the cross-linking reaction was carried out at a constant temperature of 95°C for 60 minutes, then stirred and cooled to room temperature to prepare a new nano-modified composite coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com