Nano coating preservation packaging material special for traditional red egg, preparation method and coating method

A technology for coating fresh-keeping and packaging materials, which is applied in the direction of livestock slaughtering table/slaughtering support, etc., can solve the problems of high packaging cost, low efficiency, complex production process, etc., to reduce labor costs, improve production efficiency, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

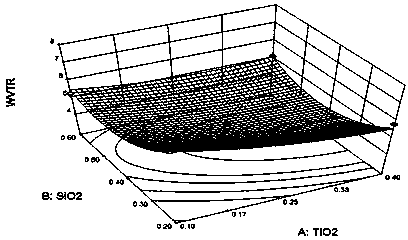

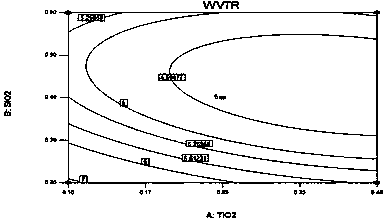

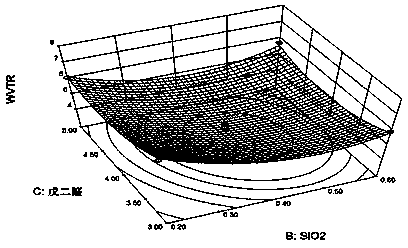

[0033] According to the special nano-coated film fresh-keeping packaging material for traditional red eggs of the present invention, its preparation method is: a certain amount of nano-TiO 2 , nano-SiO 2 Add it to 50g / L PVA aqueous solution according to the proportion, place it in an ultrasonic water bath, and ultrasonicate it for 15-20 minutes under the condition of power density 70-80W / L to make nano-TiO 2 and SiO 2 Uniformly disperse in polyvinyl alcohol aqueous solution, heat and stir the mixed solution until the temperature reaches 85-95°C, add a certain amount of glutaraldehyde into the above-mentioned nanomaterial-polyvinyl alcohol mixed solution, keep stirring for 40-50 minutes; mix 1.2g / L acid red (azorubin) is added to the above-mentioned glutaraldehyde-nanomaterial-polyvinyl alcohol solution, and stirred at constant temperature for 10-20 minutes to prepare a composite nano-coating material.

[0034] Among them, nano-TiO 2 , nano-SiO 2 The addition amount of glu...

Embodiment 2

[0043] Nano TiO 2 , nano-SiO 2 Add the ratio of 0.1g / L and 0.2g / L to 40g / L PVA aqueous solution, put it in an ultrasonic water bath, and ultrasonicate for 15 minutes at a power density of 80W / L to make nano-TiO 2 and nano-SiO 2 Uniformly disperse in polyvinyl alcohol aqueous solution; heat and stir the mixed solution until the temperature reaches 88°C, add glutaraldehyde in the ratio of 3g / L to the above-mentioned nanomaterial-polyvinyl alcohol mixed solution, keep stirring for 45 minutes; mix 1.2g / L Add L acid red (azorubin) into the above-mentioned glutaraldehyde-nano material-polyvinyl alcohol solution, and stir at constant temperature for 15 minutes to prepare a composite nano-coating material. The film-forming performance of the composite coating fresh-keeping packaging material was tested, and the moisture permeability was found to be 6.077 g*m -2 *h -1 , The diameter of the inhibition zone is 20.14mm.

Embodiment 3

[0045] Nano TiO 2 , nano-SiO 2 Do not add 0.4g / L, 0.6g / L to 70g / L PVA aqueous solution, put it in an ultrasonic water bath, and ultrasonicate for 15 minutes under the condition of power density 80W / L to make nano-TiO 2 and nano-SiO 2 Uniformly disperse in polyvinyl alcohol aqueous solution; heat and stir the mixed solution until the temperature reaches 88°C, add glutaraldehyde into the above-mentioned nanomaterial-polyvinyl alcohol mixed solution at a ratio of 5g / L, keep stirring for 45 minutes; mix 1.2g / L Add L acid red (azorubin) into the above-mentioned glutaraldehyde-nano material-polyvinyl alcohol solution, and stir at constant temperature for 15 minutes to prepare a composite nano-coating material. The film-forming performance of the composite coating fresh-keeping packaging material was tested, and the moisture permeability was found to be 4.775 g*m -2 *h -1 , The diameter of the inhibition zone is 21.43mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com