Drive motor control system and control method of laser-boring optical element

A technology for driving motor control and optical components, which is used in laser welding equipment, manufacturing tools, welding equipment, etc., and can solve problems such as the error between the motor speed ratio and the preset value, and the inability to guarantee the accuracy of graphics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

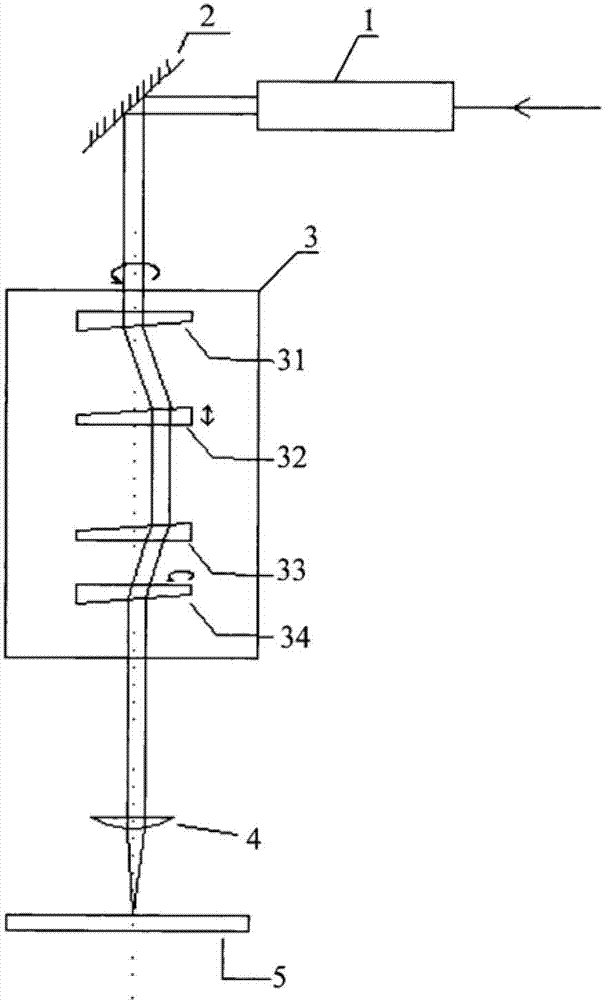

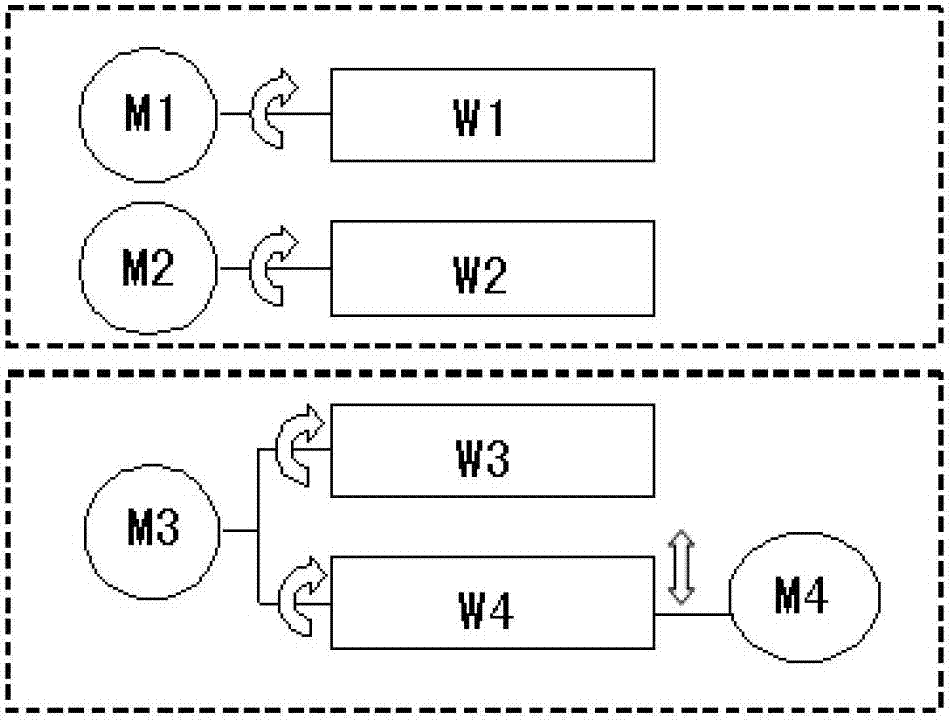

[0035] Such as figure 2 As shown, the controlled object of the present invention is as figure 2 Shown is: four motors M1-M4 that drive the four optical wedges 1-4 to move. Among them: the optical wedges W1 and W2 are driven by the motors M1 and M2 respectively, and the optical wedges W3 and W4 are both driven by the motor M3 to rotate. At the same time, the optical wedge W4 can also move up and down through the drive of the motor M4 to pull apart the optical wedge. The distance between W3. It can be seen from the optical principle that when rotating, if the deviation angle is formed between the optical wedges W1 and W2, the rotating beam will produce a radius of rotation; if the distance between the optical wedges W3 and W4 along the optical axis makes the rotating light speed A lateral displacement is generated, and after passing through the focusing mirror, a beam of rotating light with a taper will be formed.

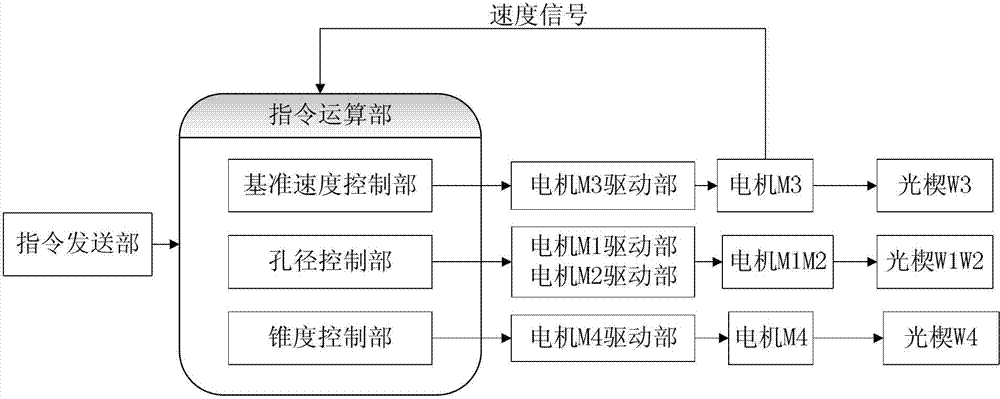

[0036] Such as image 3 Shown: the control system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com