Device and method for processing laser direct imaging

A technology of laser direct imaging and processing equipment, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of reduced productivity and product quality, poor line width repeatability, and impact on precision, and achieve processing efficiency High, simple operation, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

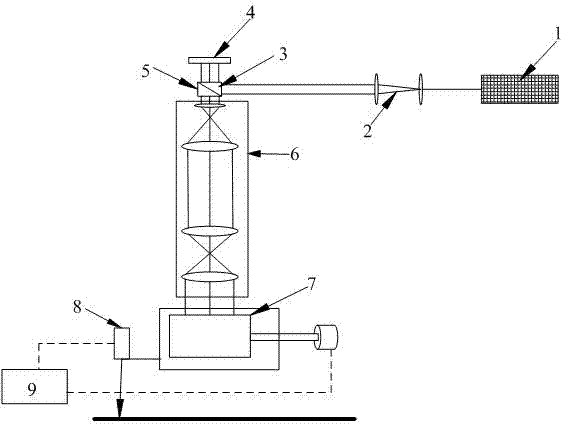

[0016] Such as figure 1 As shown, the laser direct imaging processing device is arranged with a first beam expander 2 at the output end of the ultrashort pulse laser 1, and the output end of the first beam expander 2 is provided with a first 45-degree half mirror 3, and the first 45 The reflection output end of the half-mirror 3 is arranged with a DLP chip 4, the output end of the DLP chip 4 is arranged through the second 45-degree half-mirror 5, and the transmission output end of the second 45-degree half-mirror 5 is arranged with a second beam expander Mirror 6, the second beam expander mirror 6 is facing the working platform, the working platform includes an X-axis transmission unit, a Y-axis transmission unit and a high-temperature-resistant ceramic substrate, and the X-axis transmission unit includes an X-axis slide rail and controls the movement of the X-axis slide rail The Y-axis transmission unit includes the Y-axis slide rail and the motor that controls the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com