Steel ball cleaning and drying equipment

A technology of drying equipment and steel balls, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of affecting the process, process disconnection, time-consuming and labor-intensive, etc., to improve work efficiency, improve product quality, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

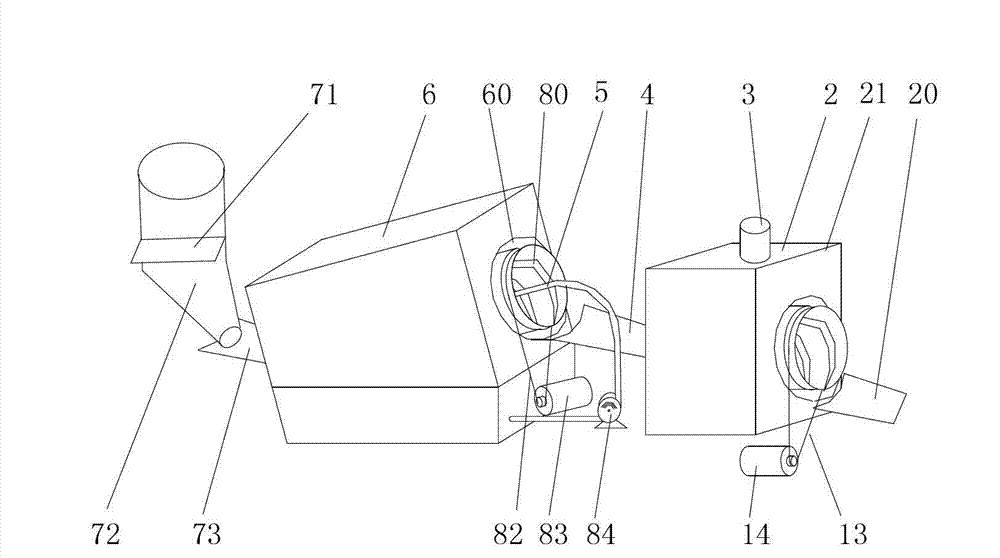

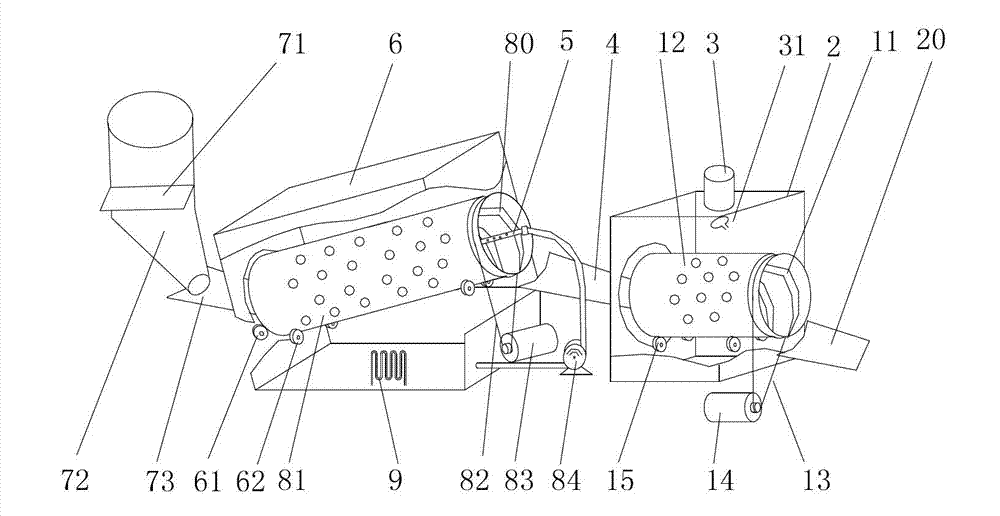

[0028] Now in conjunction with accompanying drawing, the present invention will be further described:

[0029] like figure 1 , figure 2 As shown, a steel ball cleaning and drying equipment is composed of cleaning and drying equipment. The cleaning equipment includes:

[0030] The cleaning box 6 is composed of upper and lower parts, the upper part is inclined, and round holes 60 are provided at both ends, and the lower part is used to hold cleaning liquid;

[0031] Cleaning drum 81 is arranged concentrically with circular hole 60 and is supported by two pairs of cleaning rollers 62 and anti-skid bearings 61. The peripheral surface of cleaning drum 81 is provided with a through hole smaller than the diameter of the steel ball, and the inner peripheral surface is fixed with a steel ball for conveying steel balls. The spiral plate 80 of the ball, the cleaning roller 62 and the anti-skid bearing 61 are fixed on the cleaning box 6;

[0032] The spray pipe 5 has a hole for sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com