Dry purifying device for coating

A purification device and coating technology, which can be used in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as shortening, and achieve the effects of reducing purification costs, easy handling and lifting, and shortening distance routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

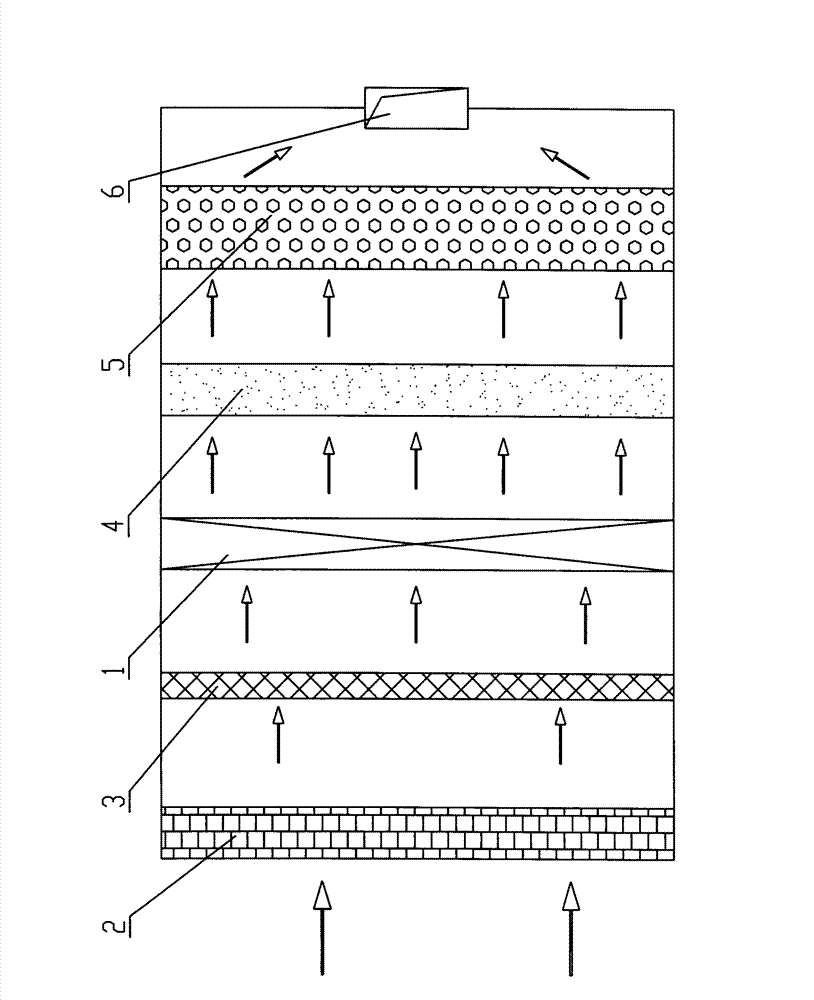

[0009] Such as figure 1 As shown, the dry coating purification device includes: an exhaust fan 1 connected to the exhaust pipe and a filter plate 2, a glass fiber filter 3 connected to the filter plate 2, and a paper filter connected to the glass fiber filter 3 Quality filter bag 4, activated carbon filter device 5 connected with paper filter bag 4 and discharge chimney 6 connected with activated carbon filter device 5.

[0010] When the above-mentioned dry-type coating purification device is used, an exhaust channel is set on the ground of the spraying workplace, and the exhaust duct is connected to the exhaust fan 1. The wind speed of the exhaust fan 1 is controlled by a frequency converter, and can be adjusted by a manual potentiometer. The output power of the exhaust fan. The exhaust fan starts to run, and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com