Separator with increased puncture resistance

A diaphragm and organic technology, applied in the field of diaphragm, can solve the problems of increasing battery resistance and reducing porosity, and achieve high tear strength, improved mechanical stability, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

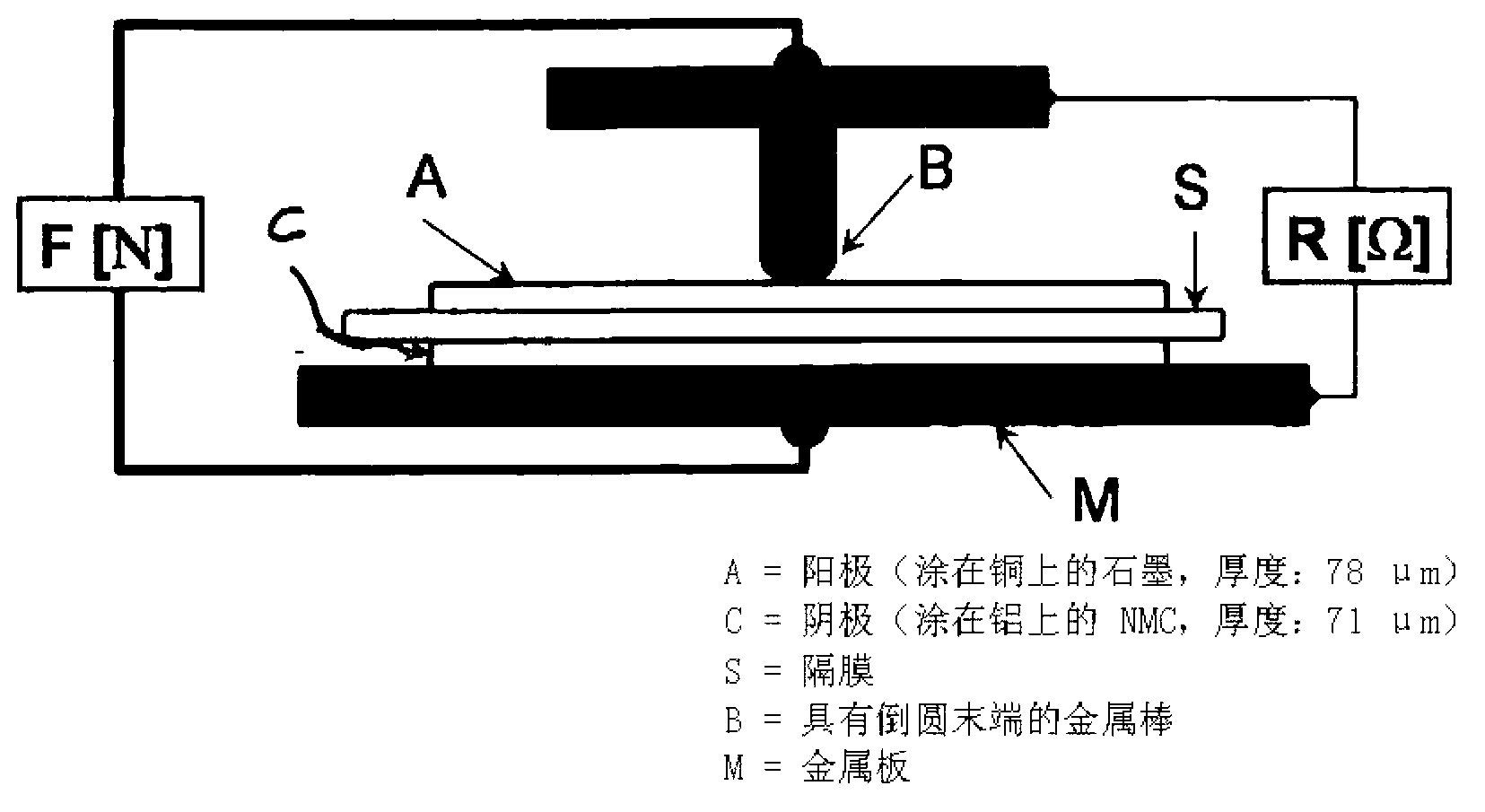

Image

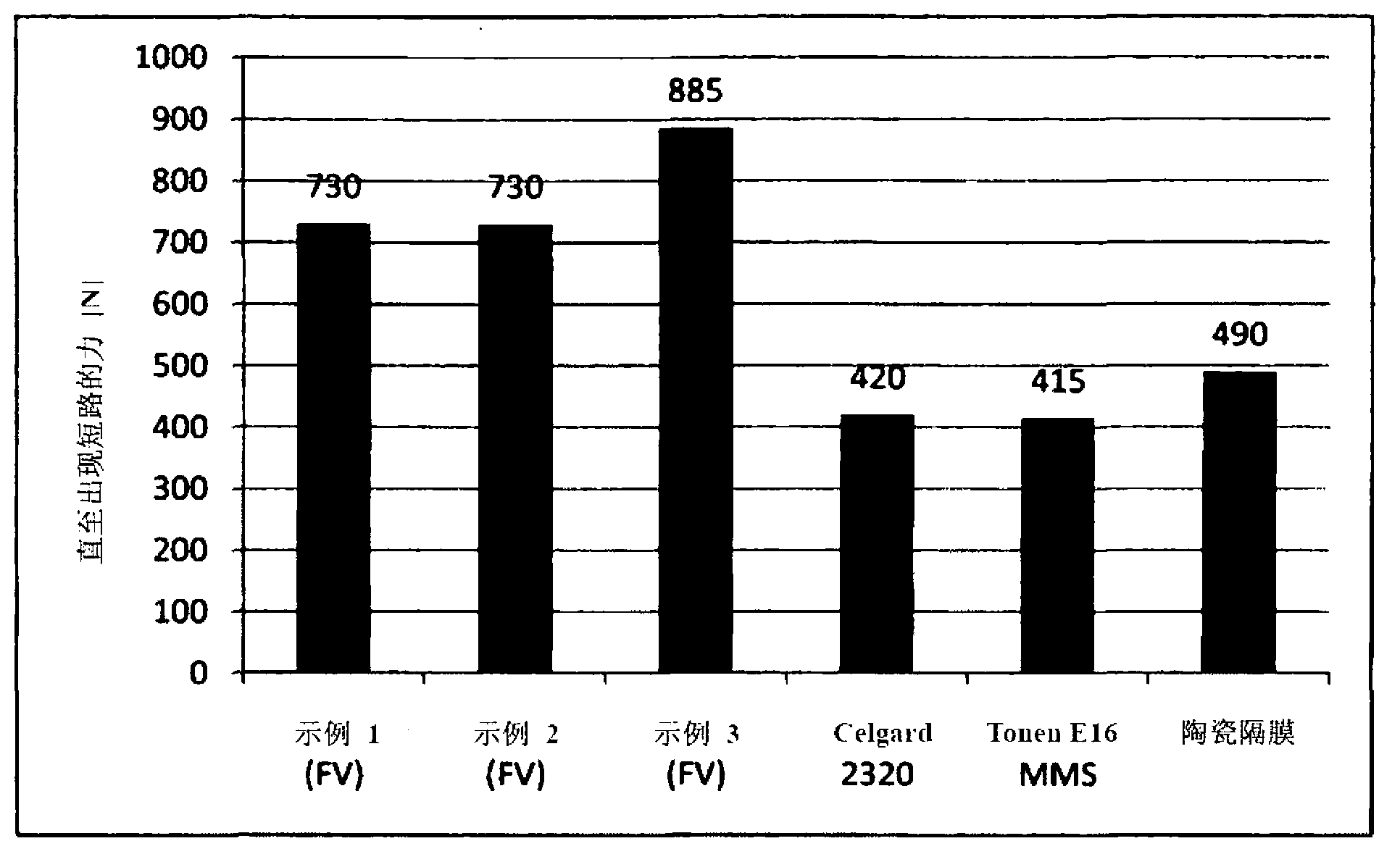

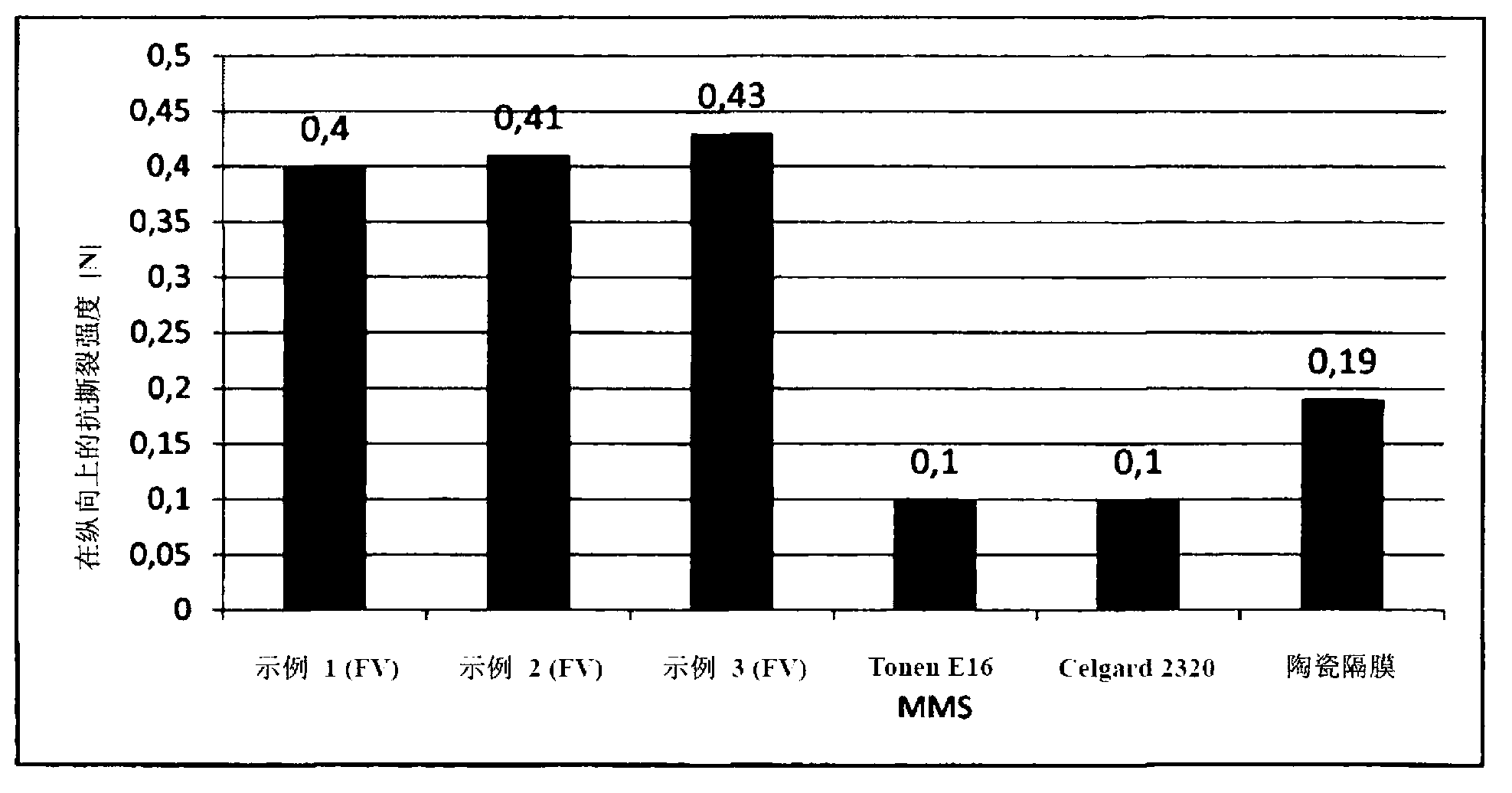

Examples

example 1

[0083] 221 parts of 70% alumina dispersion (Al 2 o 3 )(d 50 =0.7 μm) were added to 251 parts of a 2.5% hydroxymethylcellulose solution and stirred for 30 minutes. Then 10 parts of alkylphenol ethoxylates were added, followed by 24 parts of a 48% colloidal NBR dispersion (pH=9.6; TG=-12°C (glass transition temperature)), while stirring. The solution was stirred for 2 hours and tested for stability for at least 24 hours. The viscosity of the obtained solution was 290 cP. The content of flexible organic binder particles on the coating is 6.3%.

[0084] coating:

[0085] Apply a 65cm wide PET non-woven fabric (thickness: 22μm, weight per unit area: 11g / m2) by roller coating method 2 ) to continuously coat the above solution, and then dry it without contact at a temperature of 125°C. Obtain a weight per unit area of 49g / m 2 And a coated non-woven fabric with a thickness of 40 μm. The average pore size of the coated nonwoven was 0.2 μm.

example 2

[0087] 46594 parts of 66% alumina dispersion (Al 2 o 3 , d 50 = 2.5 μm) were added to 98010 parts of a 1.5% hydroxymethylcellulose solution and stirred for 30 minutes. Then add 3000 parts of alkylphenol ethoxylates, followed by adding 5396 parts of 48% flexible colloidal NBR dispersion (pH=9.6; T G = -12°C) while stirring. The solution was stirred for 3 hours and tested for stability for at least 24 hours. The viscosity of the obtained solution was 100 cP. The solids content of the flexible organic binder particles on the coating was 7.4%.

[0088] coating:

[0089] A 58cm wide PET non-woven fabric (thickness: 19μm, weight per unit area: 11g / m2) was applied by roller coating method. 2 ) continuously coat the above solution, and then dry it at 120°C. Obtain a weight per unit area of 35g / m 2 And impregnated non-woven fabric with a thickness of 36 μm. The average pore diameter is 0.2 μm.

example 3

[0091] 221 parts of 65% alumina suspension (Al 2 o 3 , d 50 = μm) was added to 251 parts of a 2% hydroxymethylcellulose solution and stirred for 30 minutes. Then 5 parts of alkylphenol ethoxylates were added, followed by 40 parts of a 48% colloidal NBR dispersion while stirring. The solution was stirred for 3 hours and tested for stability for at least 24 hours. The viscosity of the obtained solution was 290 cP. The solids content of the flexible organic binder particles was 11.1%.

[0092] coating:

[0093] A 58cm wide PET non-woven fabric (thickness: 20μm, weight per unit area: 11g / m2) was applied by roller coating method. 2 ) continuously coat the above solution, and then dry it at 120°C. Obtain a weight per unit area of 31g / m 2 And impregnated non-woven fabric with a thickness of 34 μm. The average pore diameter is 0.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com