A method and a reactor for mixing one or more chemicals into a process liquid flow

A technology of chemical products and reactors, applied in the direction of chemical instruments and methods, fluid mixers, mixers, etc., can solve the problems of increased risk and increased incidence, and achieve the effect of uniform mixing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

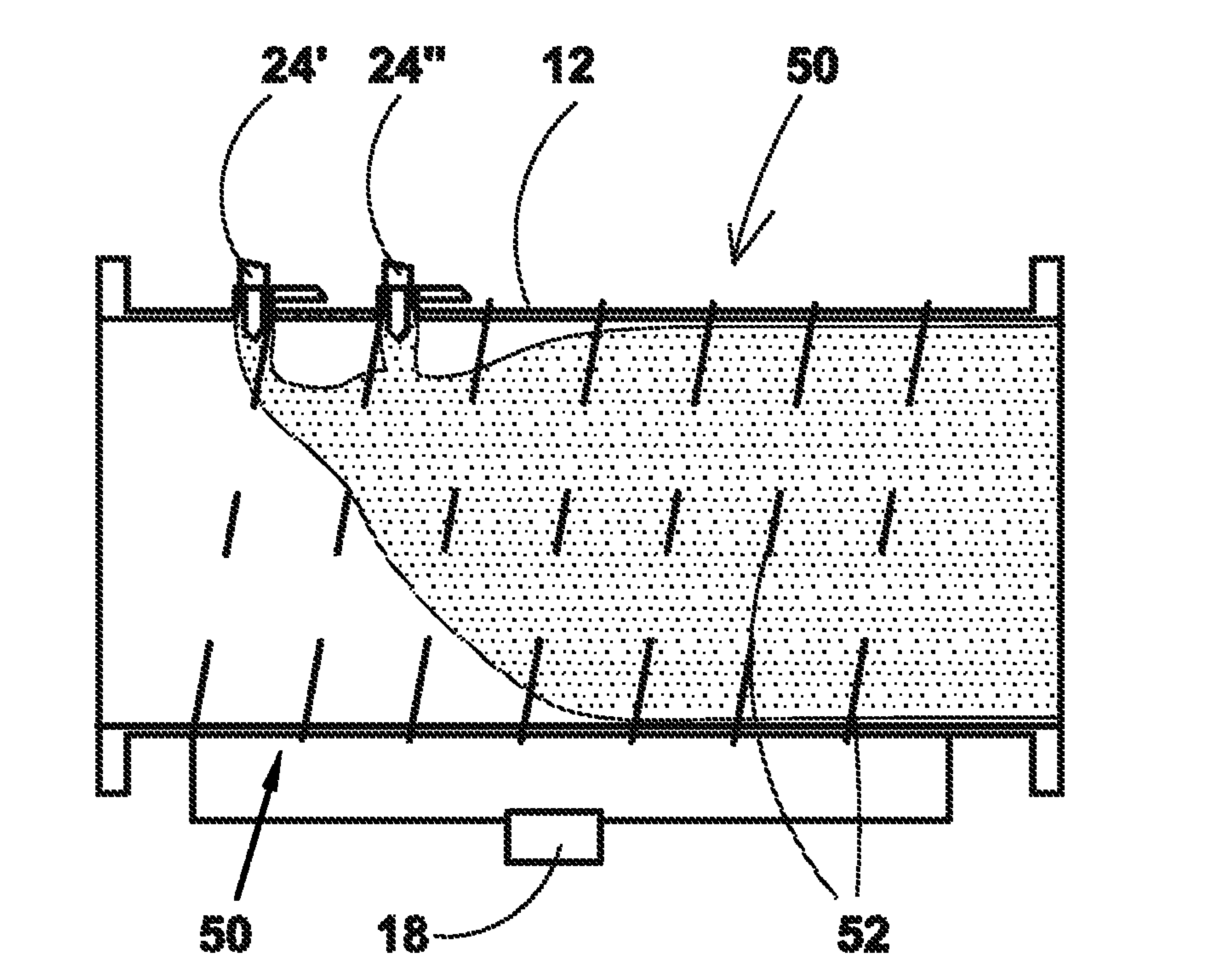

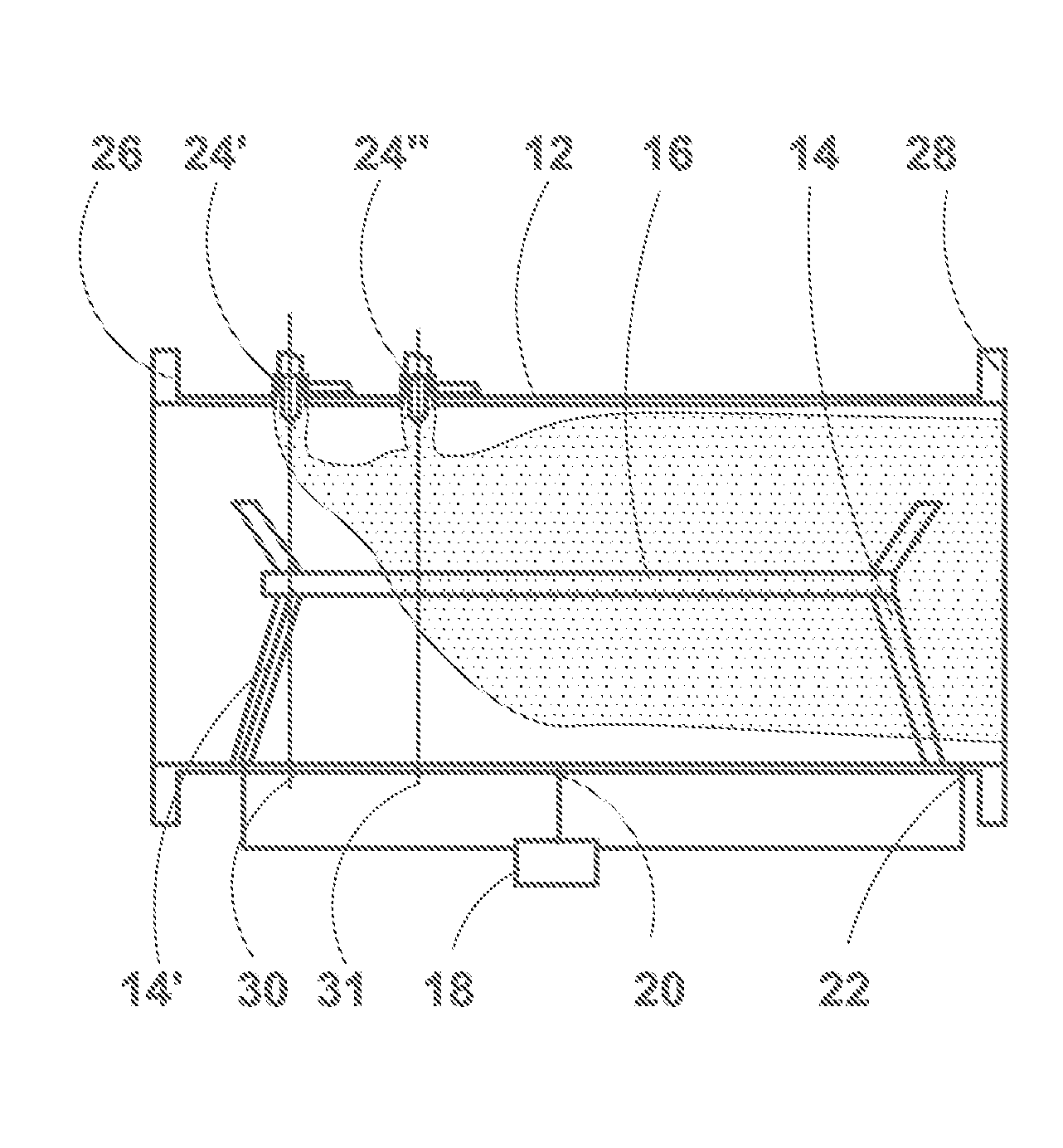

[0044] Figure 1a and Figure 1b A reactor 10 according to a preferred embodiment of the present invention is shown relatively schematically. The reactor 10 in Figure 1 comprises a straight cylindrical flow tube 12 inside the reactor 10 at a distance from the inner surface of the wall of the reactor, preferably at least one electrically conductive electrode substantially in the center of the flow tube The rod 16 is fastened by means of an arm 14, in this embodiment the rod is electrically connected via an arm 14' to a control system 18, preferably comprising a voltage source. Where the flow tube 12 is made of metal, as it is in most cases, the electrode rod 16 must be electrically isolated from the flow tube 12 . This is performed, for example, by arranging the fastening arm 14 and the fastening arm 14' of the rod 16 to consist of a non-conductive material, or by making the rod 16 mainly from a non-conductive material and coating a suitable portion of the rod with a conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com