Light emitting diode (LED) pulse drive circuit and drive method thereof

A technology of pulse drive and drive circuit, which is applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of low life expectancy of LED, mismatch of service life and long service life, etc., to achieve The effect of long service life, extended service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

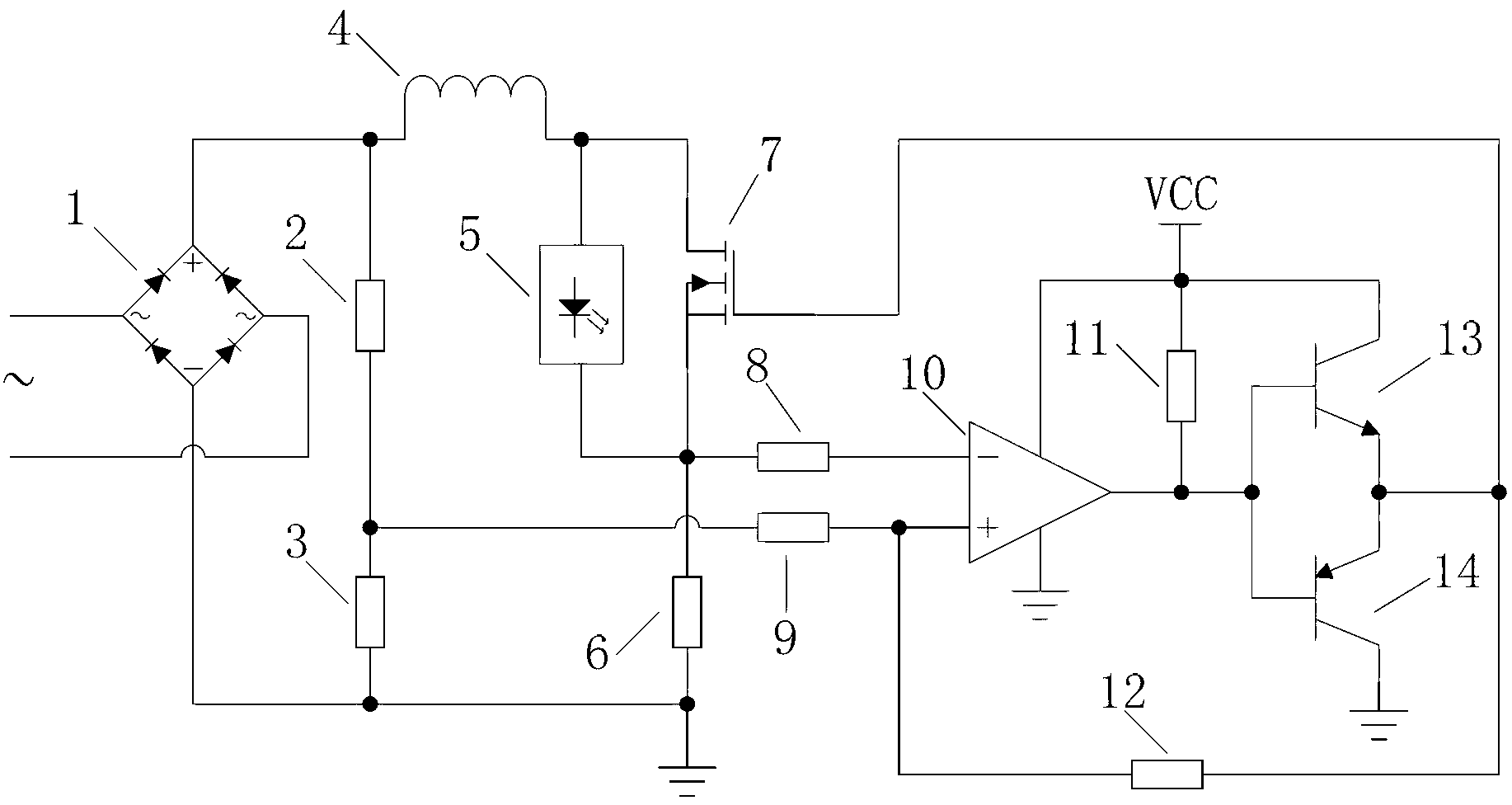

[0023] Such as figure 1 As shown, a LED pulse drive circuit includes a rectifier bridge 1, the rectifier bridge 1 has an input end and an output end, and the output end has a positive pole and a negative pole, and the LED pulse drive circuit also includes a control circuit, a switch tube drive Circuit, inductance 4, switch tube 7, LED module 5, first resistor 2, second resistor 3 and third resistor 6; one end of inductance 4 and one end of first resistor 2 are connected to the positive pole of the output end of rectifier bridge 1, The negative pole of the output terminal of the rectifier bridge 1 is connected to the reference ground, the input terminal of the rectifier bridge 1 is connected to the 220-volt single-phase AC mains, the drain of the switch tube 7 and the anode of the LED module 5 are connected to the other end of the inductor 4, and the LED module 5 The cathode of the switch tube 7 and the source of the switch tube 7 are all connected to one end of the third resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com