Contact double-shielding structure

A double shielding and contact technology, applied in switchgear, electrical components, switchgear setting and other directions, can solve the problems of unreasonable structure, poor insulation of insulating medium and easy breakdown, and achieve lower dielectric strength and avoid insulation. Material destruction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

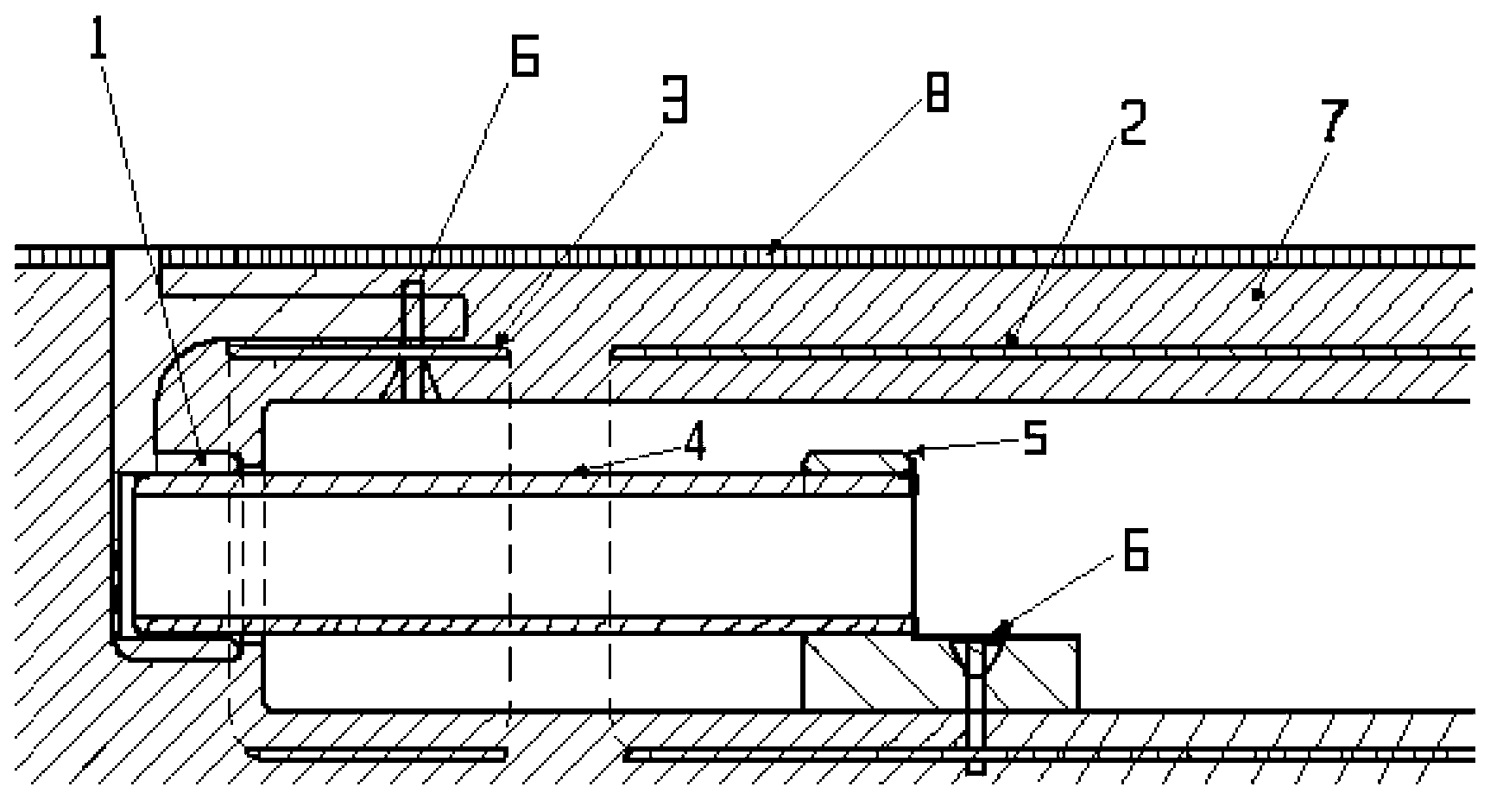

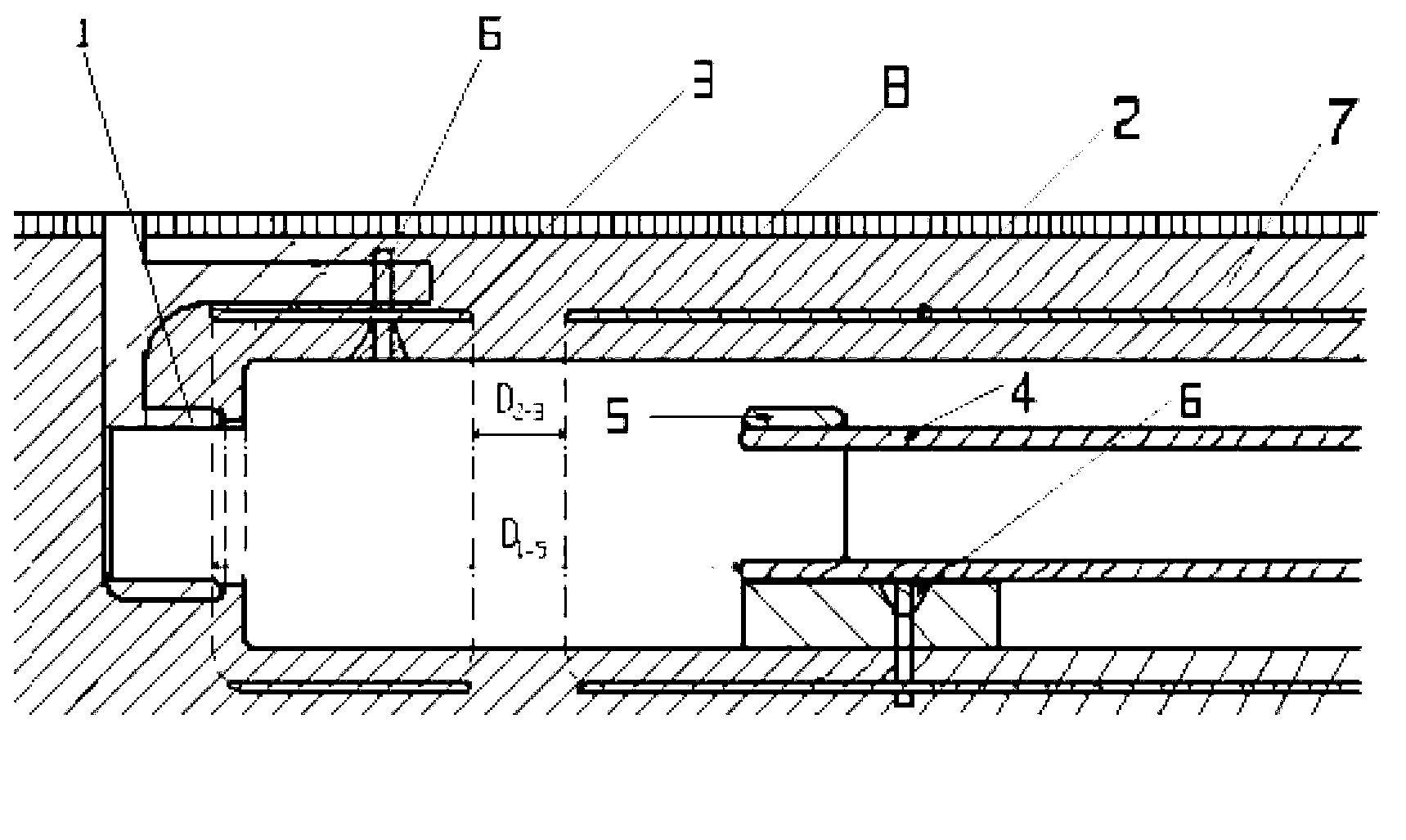

[0018] Such as figure 1 and figure 2 As shown, a contact double shielding structure of the present invention includes a first fixed contact 1, a first shielding net 3, a second shielding net 2, a moving contact 4, a second fixed contact 5, a solid insulator 7 and a grounding Conductive coating8. The first shielding net 3 and the second shielding net 2 are poured in the solid insulator 7 at intervals, and the solid insulator 7 is provided with a cavity, and the first fixed contact 1 and the second fixed contact 5 are arranged in the cavity at intervals. The fixed contact 1 is electrically connected to the first shielding net 3 through a connecting screw 6 , and the second fixed contact 5 is electrically connected to the second shielding net 2 through a connecting screw. A moving contact 4 is also provided in the cavity; a grounding conductive coating 8 is provided o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com