Safety socket

A technology for safety sockets and slots, applied in electrical components, coupling devices, circuits, etc., can solve problems such as hidden dangers of electric shock, insufficient safety protection performance, etc., achieve reliable work, reduce the probability of accidental electric shock accidents, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

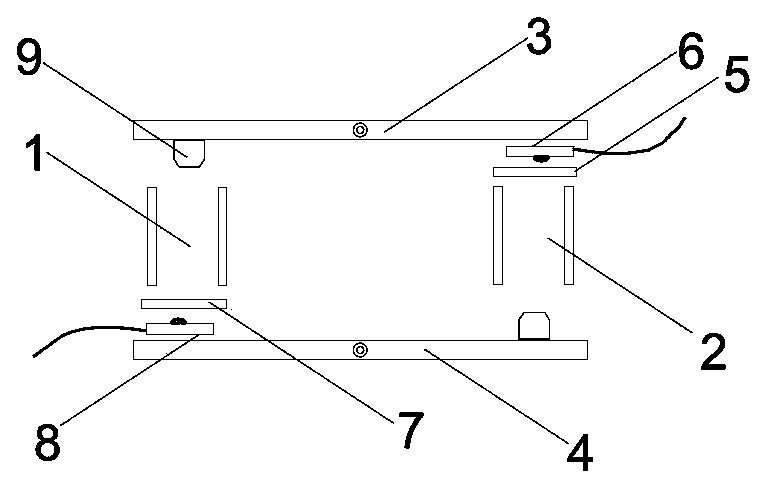

[0031] Such as figure 1 As shown, a safety socket is a two-hole socket, including a shell and a power cord, and the shell is provided with a first slot 1 and a second slot 2 parallel to each other for inserting the zero line pin and the live line pin of the plug. , between the first slot 1, the second slot 2 and the power line, there are respectively a first slot touch circuit and a second slot touch circuit that can switch current, and the first slot touch circuit includes The first touch push rod 4, the first moving guide piece 7 and the first intermediate guide piece 8, the first moving guide piece 7, the first middle guide piece 8 and the first touch push rod 4 are arranged on the inside and outside in turn. Next to the first slot 1, the second slot touch circuit includes a second touch push rod 3, a second moving guide 5 and a second middle guide 6, the second moving guide 5, and the second middle guide 6 and the second touch push rod 3 are arranged on the side of th...

Embodiment 2

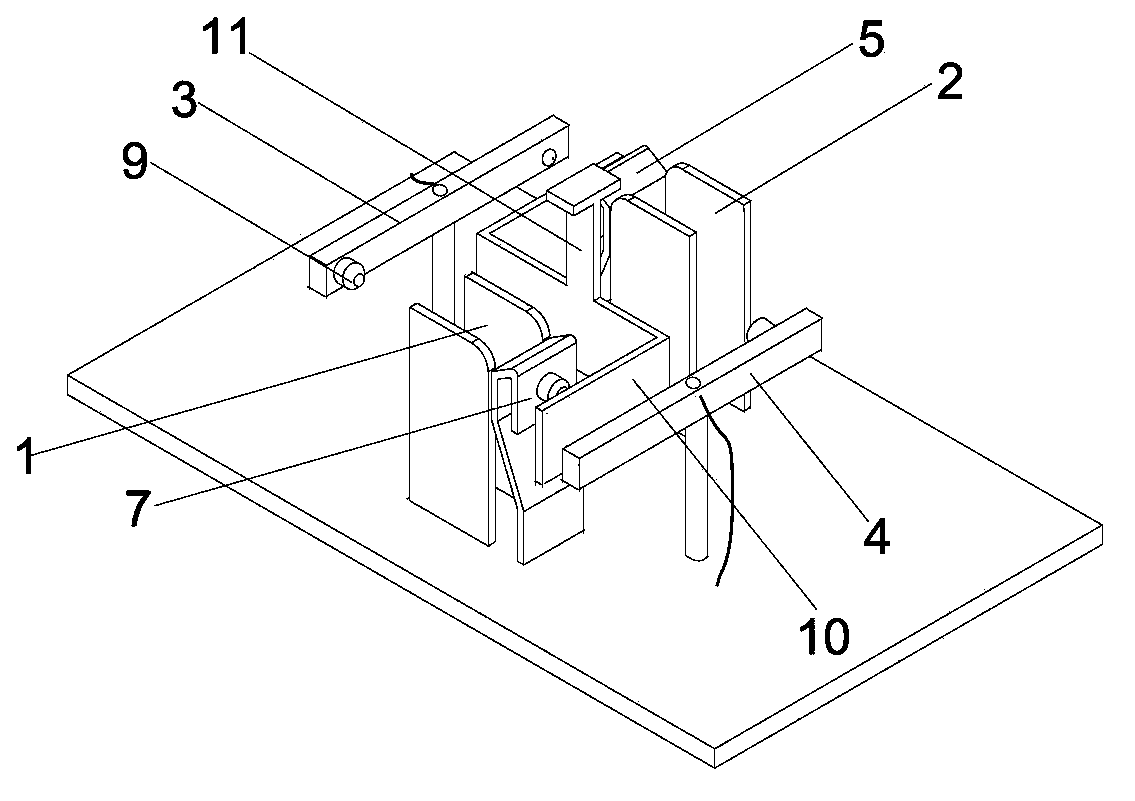

[0034] Such as figure 2 As shown, in this embodiment, the first intermediate guide 8 and the second intermediate guide 6 are not provided, the first touch push rod 4 and the second touch push rod 3 are both made of metal, and the power supply described above is connected to The endpoints are directly set on the first touch actuator 4 and the second touch actuator 3 respectively, the zero line of the power line is directly connected to the center of the first touch actuator 4, and the live wire of the power line is directly connected to the second touch actuator 3 central connections. The safety socket also includes a circuit isolating device, which includes an insulating plate frame 10 , an insulating plate frame guide groove, and an insulating plate frame pressing rod 11 . Insulating board frame 10 is stepped, and is made of plastics. At the bottom of the housing, a pair of mounting brackets are fixed between the first slot 1 and the second slot 2. The guide groove of ...

Embodiment 3

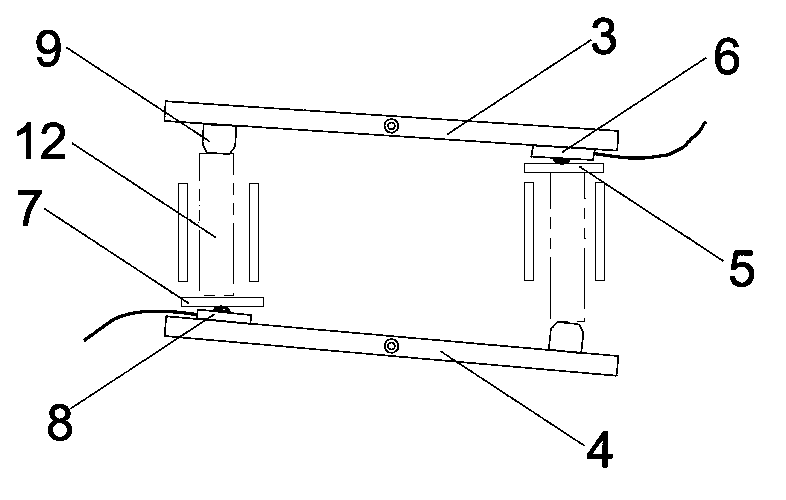

[0037] Such as Figure 5 As shown, the first slot touch circuit includes a first intermediate guide 8, the first intermediate guide 8 is arranged between the first touch push rod 4 and the first moving guide 7, the second insert The groove touch circuit includes a second intermediate guide 6, which is arranged between the second touch push rod 3 and the second movable guide 5, and the power access terminals are respectively arranged in the first middle Guide 8 and the second intermediate guide 6. The first middle guide piece 8 and the second middle guide piece 6 are respectively fixed on the ends of the first touch pusher 4 and the second touch pusher 3 by screws. Both the first touch push rod 4 and the second touch push rod 3 are made of plastic. At the bottom of the housing, a pair of mounting brackets are fixed between the first slot 1 and the second slot 2. The insulating frame guide groove 13 is composed of a pair of guide groove side plates perpendicular to the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com