Electroforming screen printing plate grid line for solar battery

A technology of solar cells and grid lines, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of thick grid printing and screen deformation, and achieve the effect of avoiding thick printing, improving printing quality, and not affecting battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

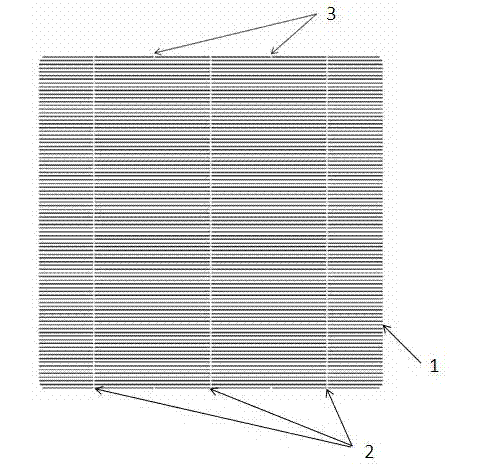

[0016] Such as figure 1 An electroformed screen grid line shown includes: a fine grid 1 and a break point 2 of the fine grid at the main grid position; there are three main grids, and the break point 3 is at the thin edge of the solar cell grid on the fence.

Embodiment 2

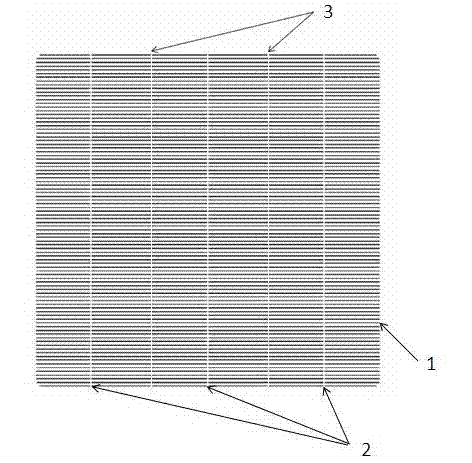

[0018] Such as figure 2 An electroformed screen grid line shown includes: a fine grid 1 and a break point 2 of the fine grid at the position of the main grid; there are three main grids, and a break point is set on the thin grid 2 in the middle of the two main grids. Point 3.

Embodiment 3

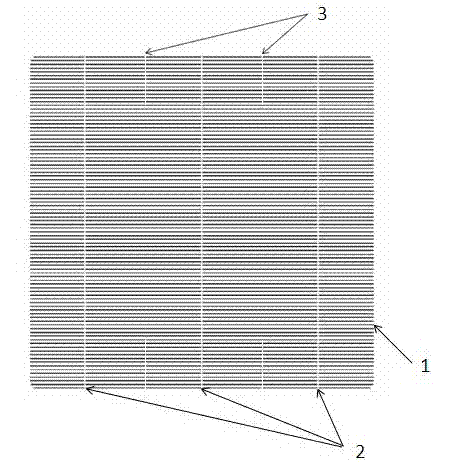

[0020] Such as image 3 An electroformed screen grid line shown includes: a fine grid 1 and a break point 2 of the fine grid at the position of the main grid; there are three main grids, and the upper part of the thin grid 2 in the middle of the two main grids is provided with a break point. Point 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com