Improved method of bipolar integrated circuit amplification coefficient process

An integrated circuit and process improvement technology, which is applied in the field of semiconductor manufacturing technology, can solve the problems of bipolar circuit amplification factor attenuation, stress characteristic circuit incomplete matching, etc., and achieve the effect of stabilizing the PNP tube amplification factor, preventing attenuation, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

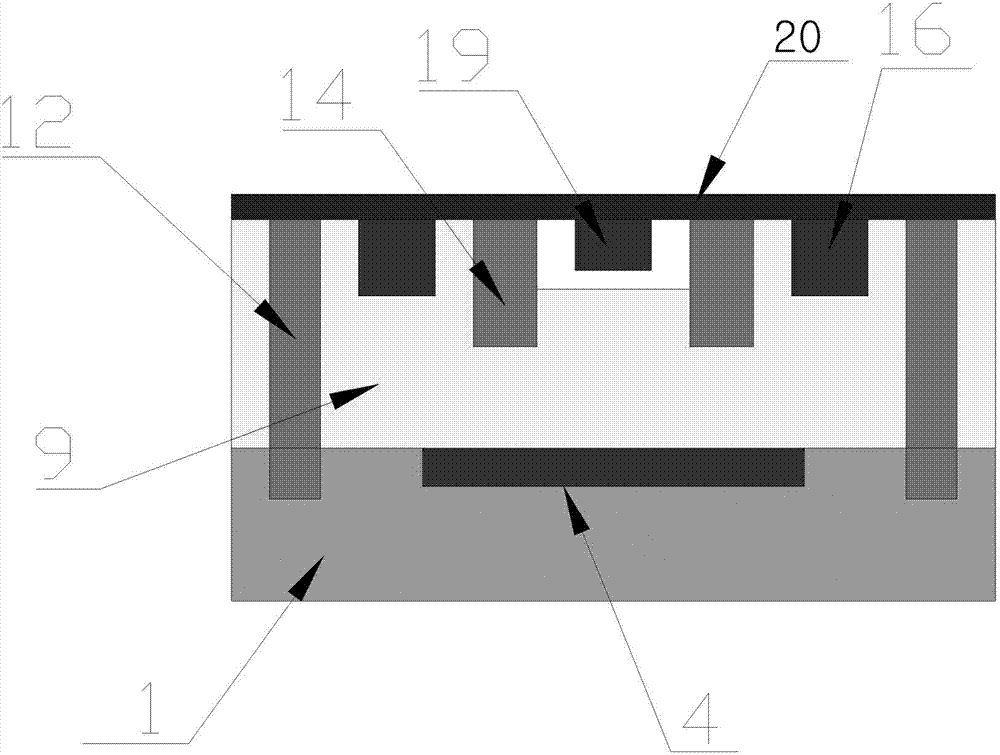

[0022] The method for improving the amplification factor process of a bipolar integrated circuit provided by the present invention includes the steps of manufacturing the basic circuit of a bipolar integrated circuit compatible with BJT and JFET by conventional technology, the step of manufacturing electrode leads on the basic circuit, and the subsequent process finishing step .

[0023] The basic circuit includes the underlying silicon P substrate 1, N - Epitaxial layer 9, P+ region 12, N+ region 4, base region boron (14), emitter region phosphorus (16) and gate region phosphorus (19).

[0024] The present invention is characterized in that the step of making electrode leads on the described basic circuit is:

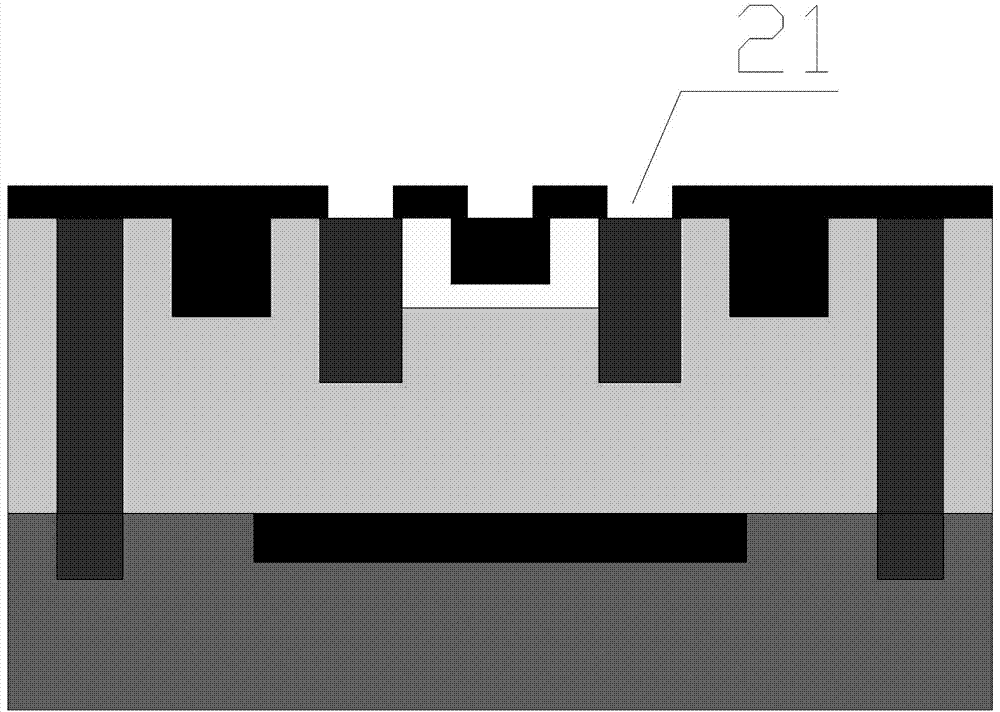

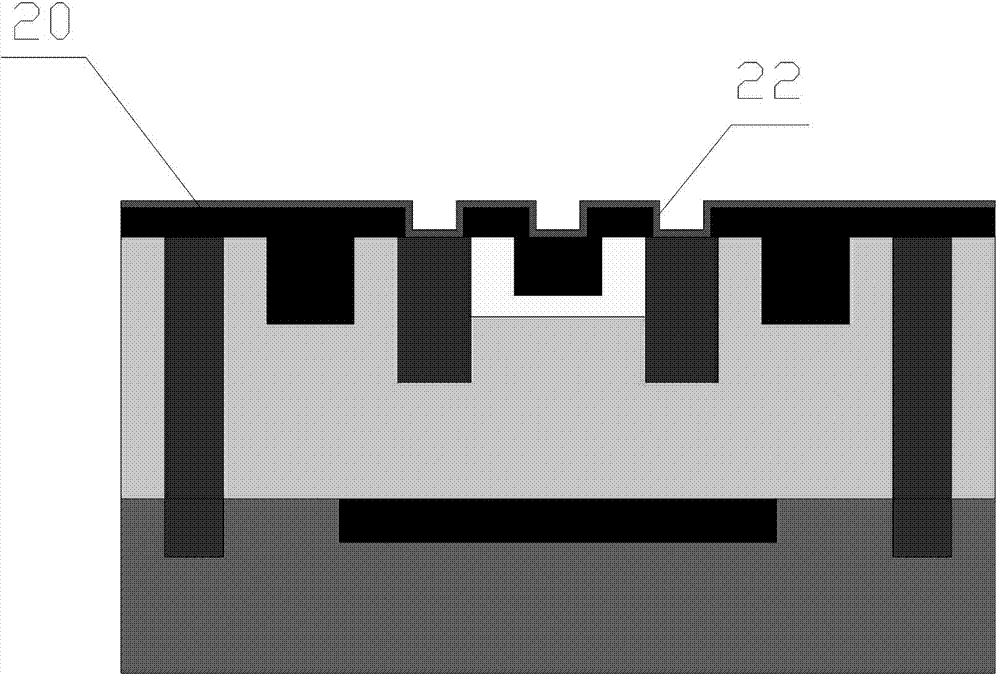

[0025] a. Depositing LTO - such as figure 1 As shown, at a furnace temperature of 420 ° C, a layer of silicon dioxide 20 of about 450 nm is deposited by LPCVD (vapor phase deposition device) as a circuit capacitor dielectric layer; then the deposited LTO layer is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com